| CLICK HERE FOR INDEX PAGE |

| |

| BASIC CUTTING WITH THE BAND SAW |

V.Ryan © 2022 |

| |

| |

| DISCLAIMER: Ensure that you have attended and passed the legally required course, for use of this machine. Ensure that you are allowed to operate the band saw, according to your country’s legal requirements. Never use this machine without expert, specialist training. |

| |

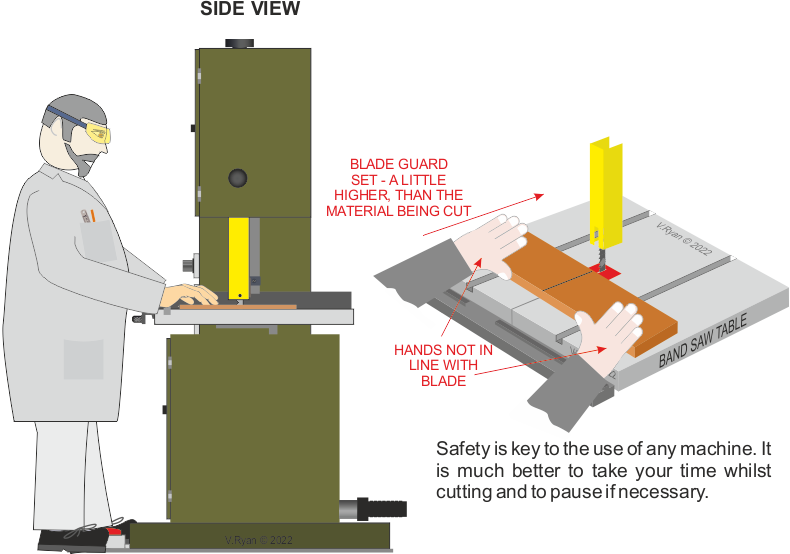

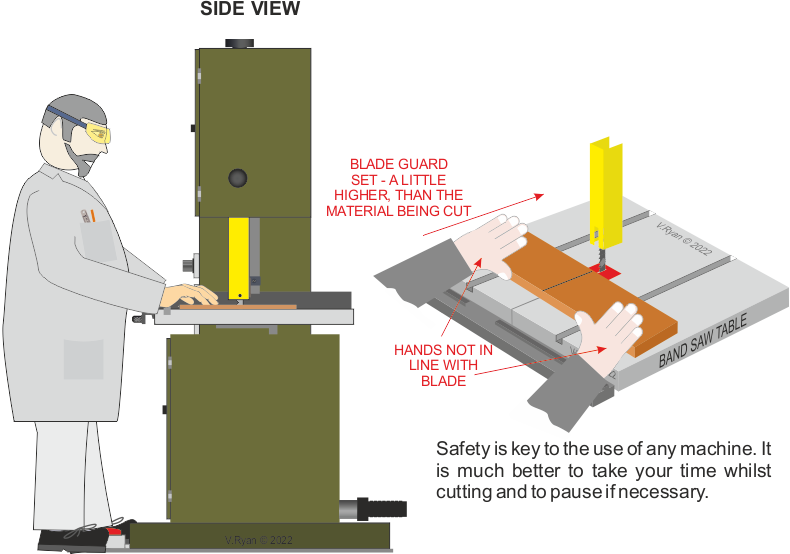

This image shows the band saw being used, without the need for a fence (free-hand cutting). Each hand is positioned to each side of the blade. This is for basic safety - if a hand slips, it will not go straight on to the sharp blade.

Set the blade guard to a little more than the thickness of the material being cut and less than the thickness of the small finger.

The material is pushed gently in the direction of the blade, until it makes contact. Gentle pushing forward continues. Experience will inform the machine operator, whether more or less forward pressure is required. If the material is fed too quickly into the blade, it may struggle to cut through the material, the blade will heat up quickly and friction against the material may even generate smoke. The blade can jam or even snap / break. |

| |

| It may be necessary to cut forward a little and then retract the material. This process can be repeated, until sawing / cutting is complete. This technique reduces the tendency of the blade to over-heat and allows waste material / dust and chippings to clear. |

| |

|

| |

|

|

| |

Only trained people should use the band saw. Ensure that you have attended and passed the legally required course. Ensure that you are allowed to operate the band saw, according to your country’s legal requirements. Never use this machine without expert, specialist training.

Wear safety clothing, including safety goggles. Follow all the usual safety rules (see the Health and Safety section of this website).

Band saws need regular maintenance checks and it is very important that there is a maintenance schedule. This includes, checking the condition of the blade, the band wheels and band bearings, guides and thrust wheels, blade tensioning and extraction. |

| |

| USING PUSH STICKS |

| |

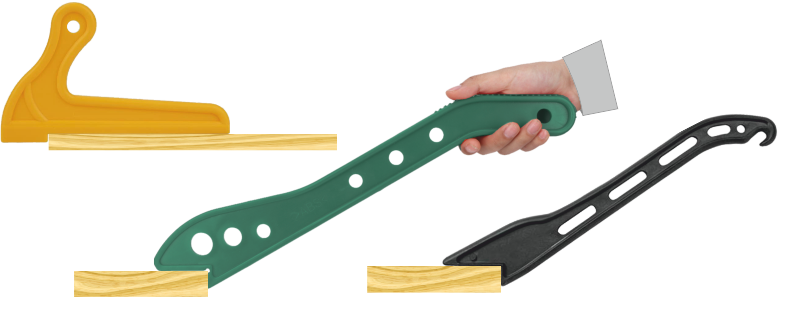

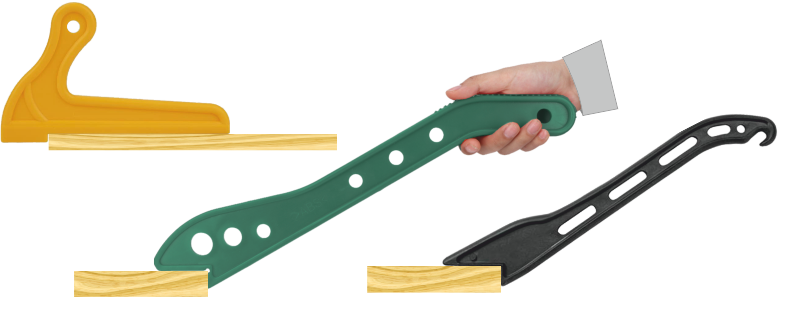

Push sticks allow the machine operator to keep his / her hands away from the band saw blade. Push sticks are usually made from wood and they are used to push material through the cutting area of the machine. The example below, shows wood being pushed along the rip fence, by two push sticks. The main advantage of this technique, is that the operators fingers are well away from the moving blade. Also, the push stick can be positioned close to the blade, helping to maintain control of the material.

Free hand cutting using push sticks is not advised. Push sticks alone do not allow the operator, to keep complete control of the material being cut. |

| |

|

| |

| Push sticks all often homemade. However, a range of different designs can be purchased (see below). |

| |

|

| |

|

|

| |

| GUIDE BLOCKS |

| |

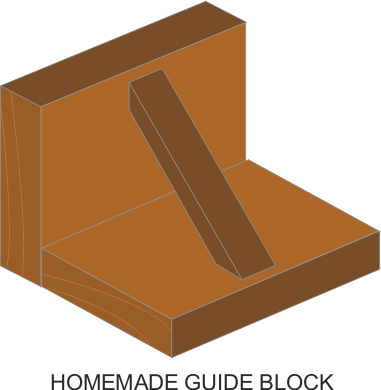

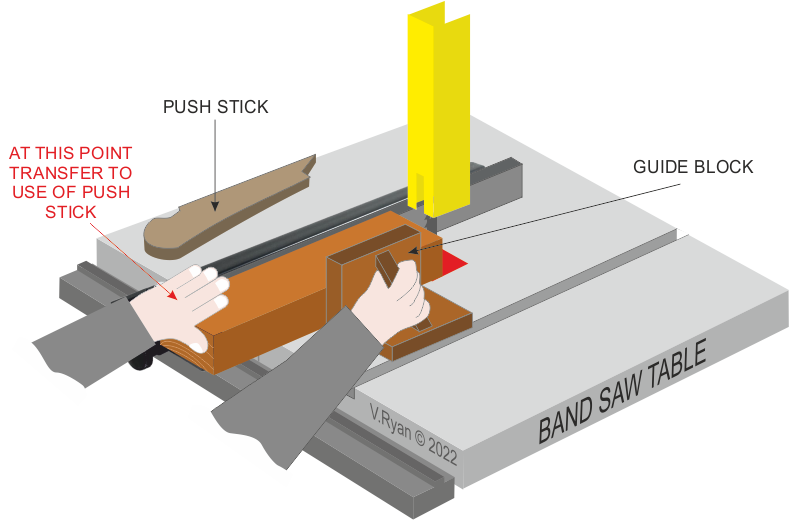

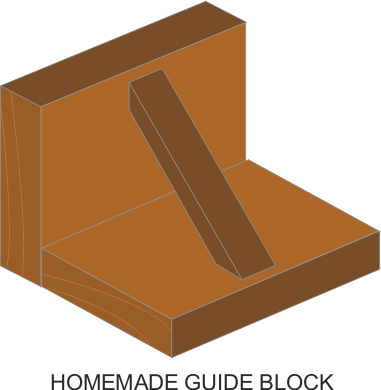

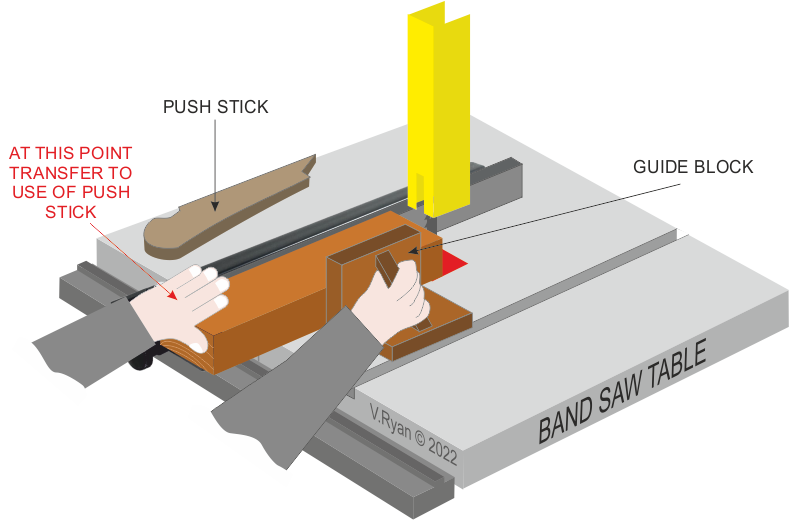

Guide blocks are very useful when feeding wood into the blade, with the aid of a rip fence. The guide block is held firmly in one hand and pressed against the material to be cut. As the material is pushed towards the blade, the guide block offers safe control and keeps hands and fingers away from the cutting area.

The diagram below, shows a guide block being used. Notice the push stick lying on the band saw’s table. When the material is pushed into the blade, there will come a point, when the machine operator will switch to the use of the push stick. This is usually when the operators hand goes over the limits of the table. In this case, this will keep his / her left hand safe and away from the blade. |

|

|

| |

|

| |

|

|

| |

| Guide blocks can be homemade or purchased (see below) |

| |

|

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|