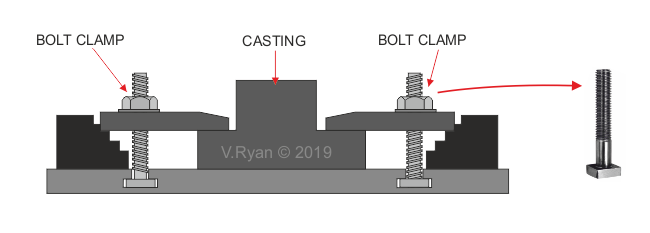

T HEAD BOLT - COUNTERSUNK - CAPTIVE MACHINE SCREW

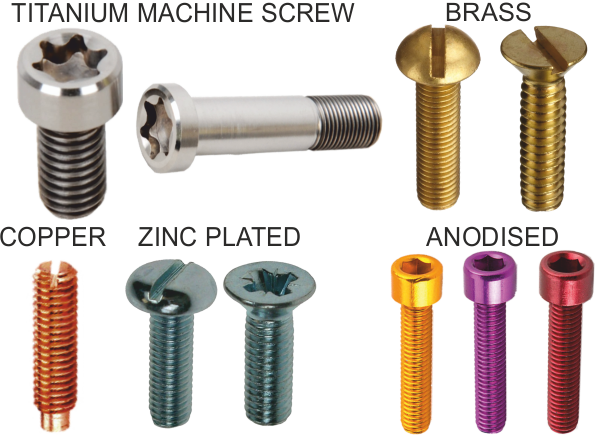

More common machine screws are manufactured from stainless steel, carbon steel, brass and even copper. Steel screws tend to be zinc plated to prevent corrosion. Machine screws are sometimes plated with, brass, copper and nickel. A more modern process applied to machine screws is anodising, which means a vast range of colours can be used. Anodising both prevents corrosion and gives an attractive finish to the machine screw.

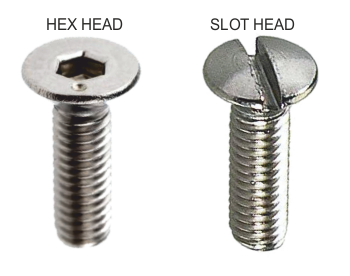

Machine screws are available with almost every description of head, such as the most common the ‘slot head’ countersunk screw, seen right

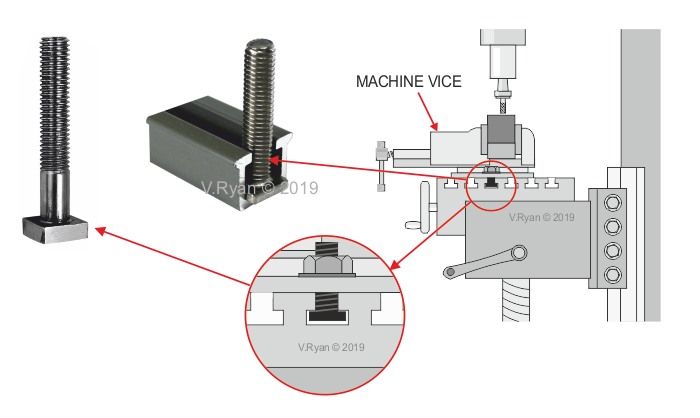

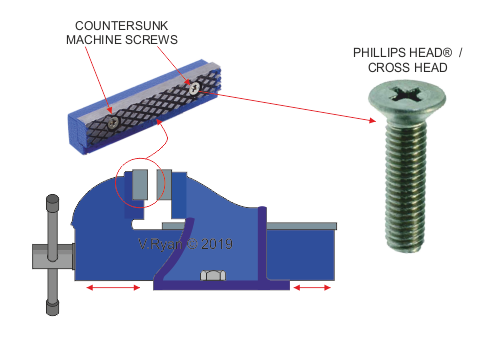

The serrated jaws of the machine vice (below), are held in position by a countersunk machine screw, with a cross head / phillips® head

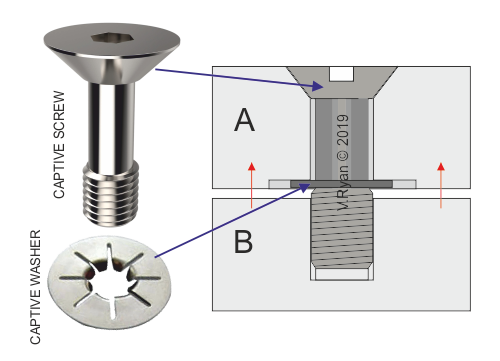

Captive screws are designed so that they cannot be removed fully when loosened. They work in combination with a captive washer.

When being fitted, the screw is placed through the first metal section (A) and then the washer. The screw can be threaded through the washer BUT not withdrawn / unscrewed. The threaded portion of the screw is then tightened into the threaded hole of the second section of material (B)