Thin gauge steel sheet and plate, can be cut with a ‘flat’ chisel. The ground edge of a flat chisel is slightly curved, as this provides greater control, in the hand of a skilled engineer.

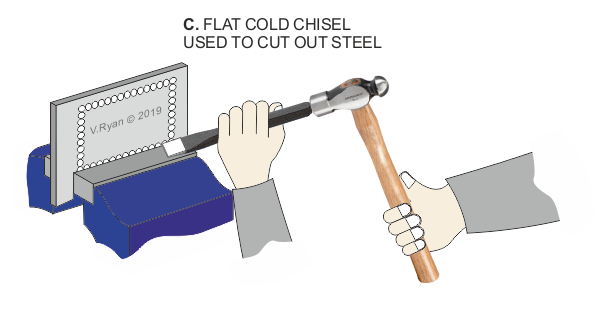

The steel is marked out with a scriber. A dot punch is used to create punch marks along the line. This makes it easier to see the scribed line. In use, the flat cold chisel is held at a slight angle to the vice. Steady blows are delivered with a ball pein hammer.

If the piece of steel sheet is too large for the engineers vice, it can be placed on a soft steel plate / block. A flat cold chisel and ball pein hammer, are then used to cut out the ‘waste’ material.

Soft steel plates / blocks are very useful, especially when centre punching and dot punching.

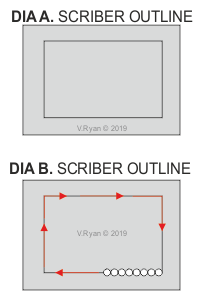

A flat cold chisel can be used to cut steel plate (see below). Streel Plate is much more difficult to cut than steel sheet. The shape is outlined with a scriber (dia A). A series of holes, very close to each other are drilled following the scriber line (dia B). Then, a flat cold chisel is used to cut out the shape (dia C).

It would be impossible to cut out the shape, without first drilling the holes first.