V.Ryan © 2022

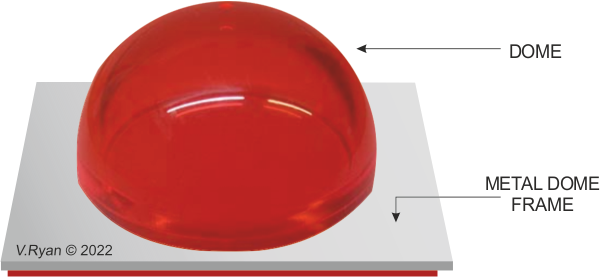

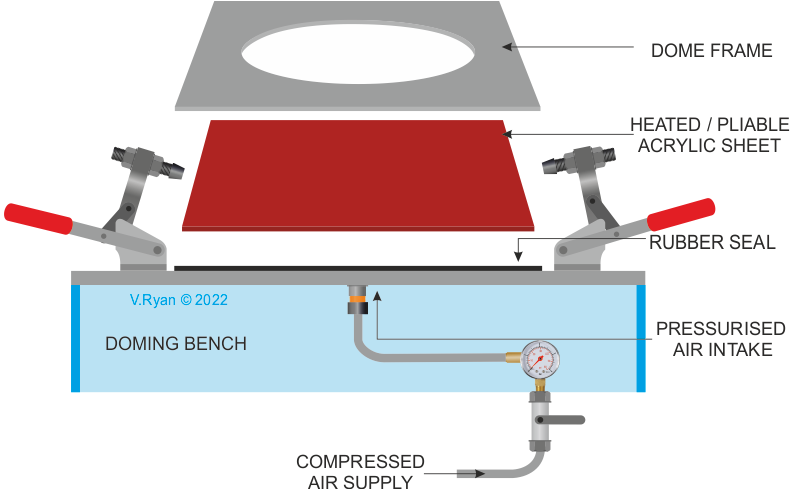

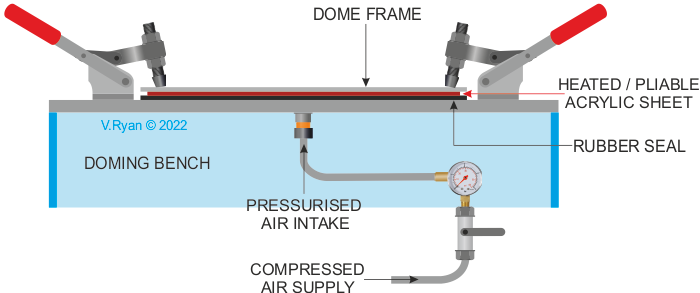

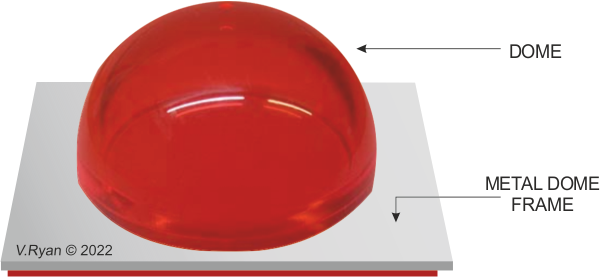

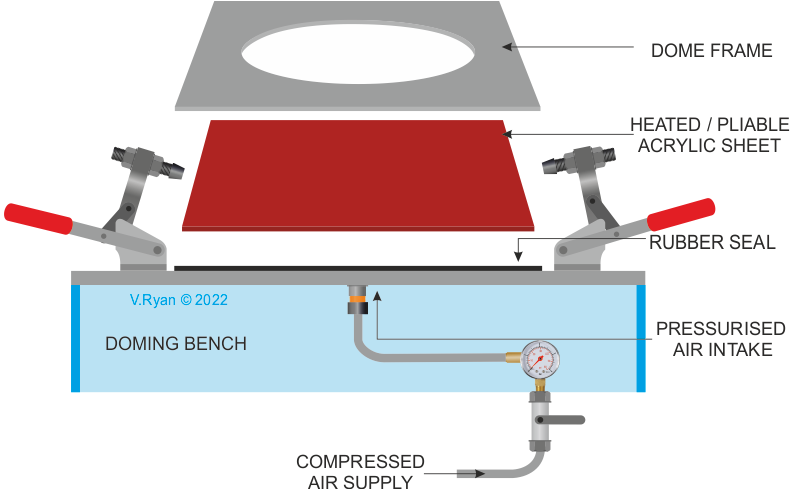

The acrylic sheet rests on a rubber mat (seal). A metal dome frame is placed accurately on top of the acrylic. The frame has an accurate circle cut out of it. This limits the overall size of the dome.

| CLICK HERE FOR INDEX PAGE |

| DOMING ACRYLIC |

V.Ryan © 2022 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

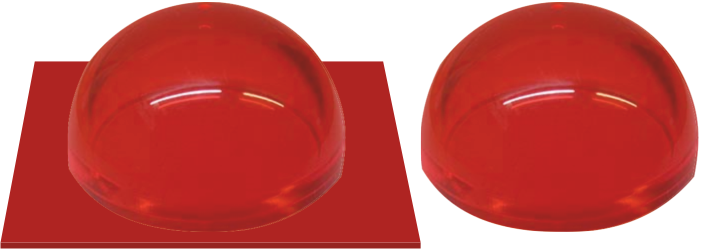

| Doming is a process, whereby a thermoplastic sheet such as acrylic, is heated in an oven and formed into a dome. Domes are very strong structures and are ideal for light covers and fitments, security camera covers, underwater devices including large scale submerged viewing areas and hygiene / display covers for food. |

|

|

| DOMING A THERMOPLASTIC SHEET - THE PROCEDURE |

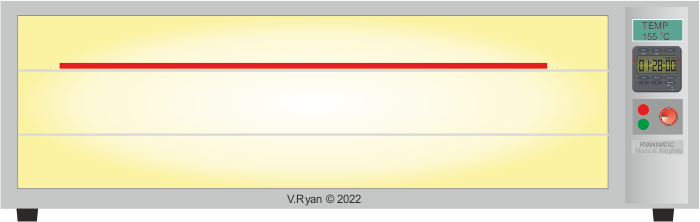

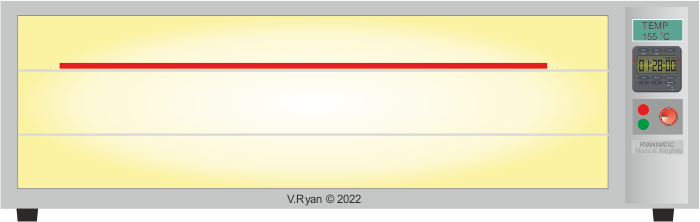

| STAGE ONE: The thermoplastic to be ‘domed’, is heated in an oven until it becomes pliable / flexible. The time required depends on the thickness and overall size of the acrylic sheet. The timer and temperature of the oven can be preset, to the required temperature and time. |

|

| STAGE TWO: When the acrylic sheet is pliable / flexible, it is removed from the oven. The acrylic must be set up on the doming bench quickly, to minimise heat loss. Any delay will allow the acrylic to cool, making it difficult to ‘dome’, or the result will be a inflexible sheet. The acrylic sheet rests on a rubber mat (seal). A metal dome frame is placed accurately on top of the acrylic. The frame has an accurate circle cut out of it. This limits the overall size of the dome. |

|

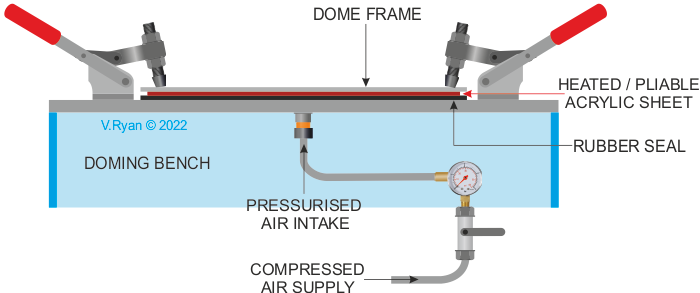

| STAGE THREE: The diagram below shows the rubber seal (rubber mat), the acrylic sheet and the doming frame clamped firmly in position. The seal between the doming bench, acrylic and dome frame must be perfect, not allowing air pressure to escape. |

|

| STAGE FOUR: The air intake is turned on, slowly allowing compressed air to form the dome. This is usually performed by a skilled worker, who has the experience to know how much air pressure to apply, at a constant, steady pace. Too much air could lead to the dome ‘bursting’ or deforming. |

|

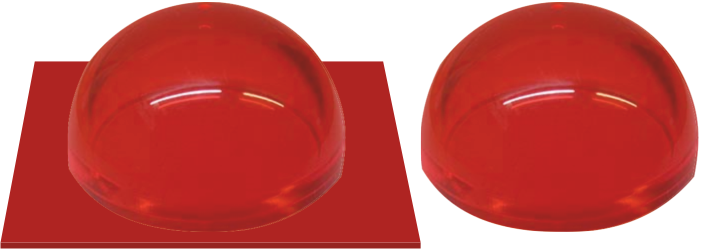

| STAGE FIVE: When the dome has cooled, it is removed from the doming clamps and the edges trimmed. |

|

| EXAMPLES OF DOMED THERMOPLASTIC PRODUCTS |

|

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

|