V.Ryan © 2022

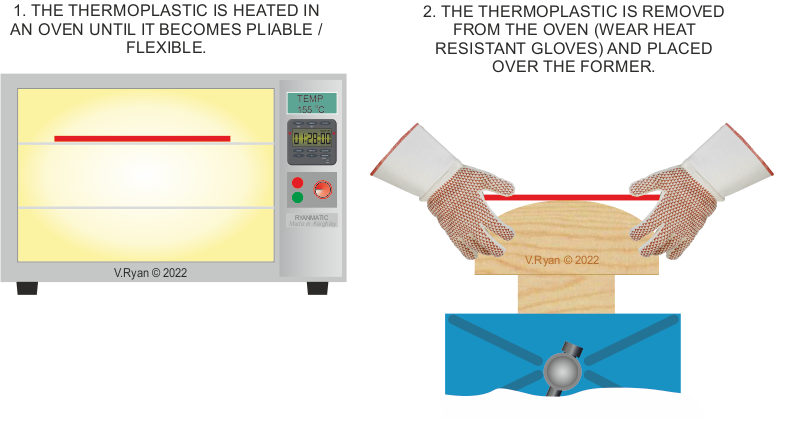

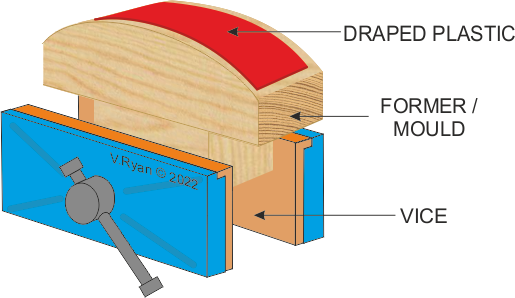

The process does not involve the use of a vacuum former, keeping costs down. The moulds / formers are usually hand made, from softwood and accurately finished.

WEAR HEAT RESISTANT GLOVES.

| CLICK HERE FOR INDEX PAGE |

| DRAPING / DRAPE FORMING OF PLASTICS |

V.Ryan © 2022 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

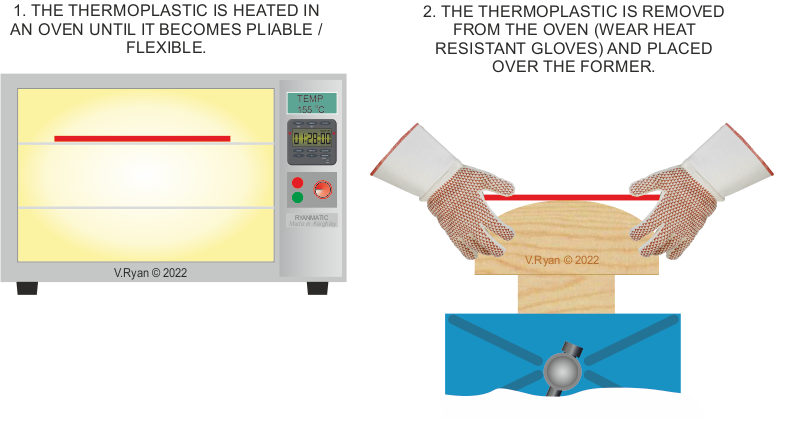

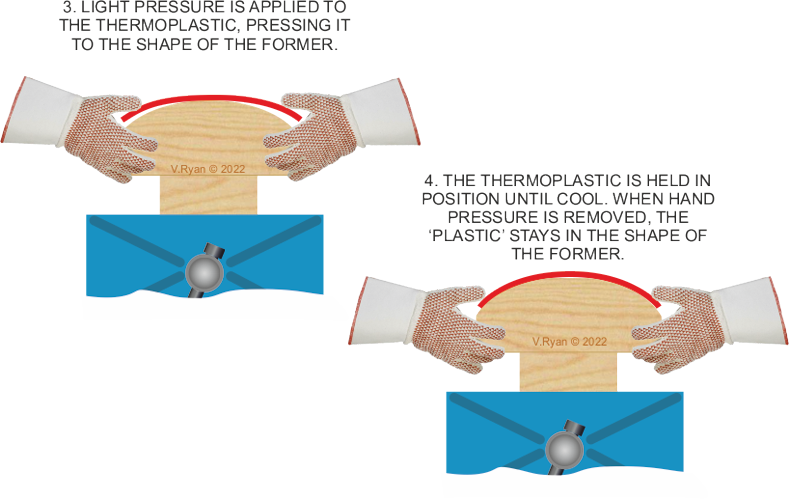

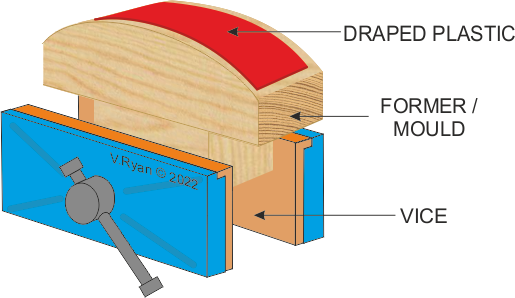

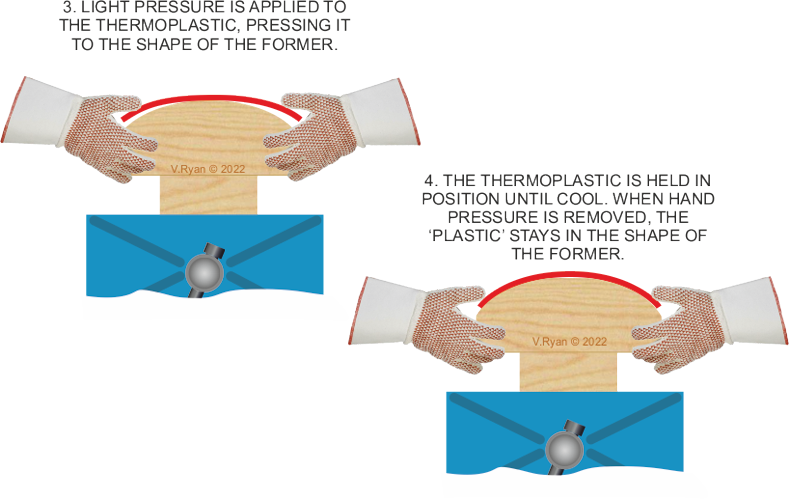

| Draping is ideal when shaping / forming plastics, as it is a relatively cheap and simple process. It involves heating a thermoplastic (e.g. acrylic) in an oven and then pressing it against a single mould (sometimes called a mandrel or former). When the plastic has cooled, it remains in the shape / form of the mould. The process does not involve the use of a vacuum former, keeping costs down. The moulds / formers are usually hand made, from softwood and accurately finished. |

|

|

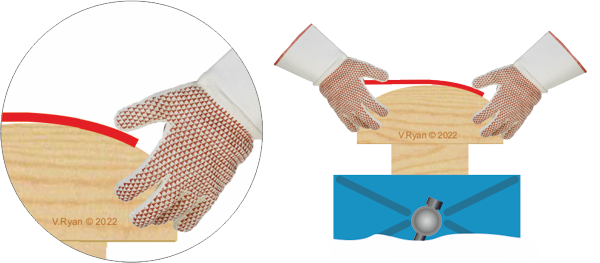

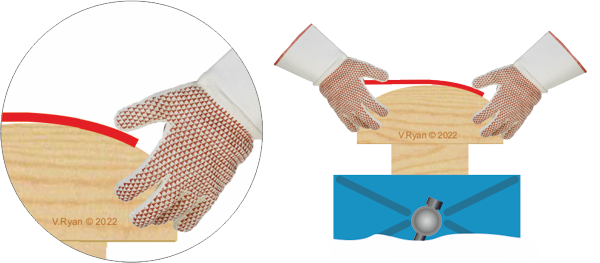

| Consider securing the former / mould in a vice before ‘forming’ the thermoplastic. Allow enough room for both hands to hold the thermoplastic in position. |

|

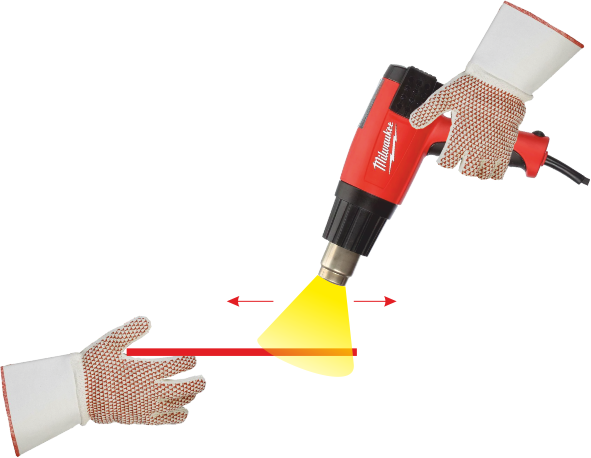

| APPLYING LOCALISED HEAT TO A SPECIFIC AREA |

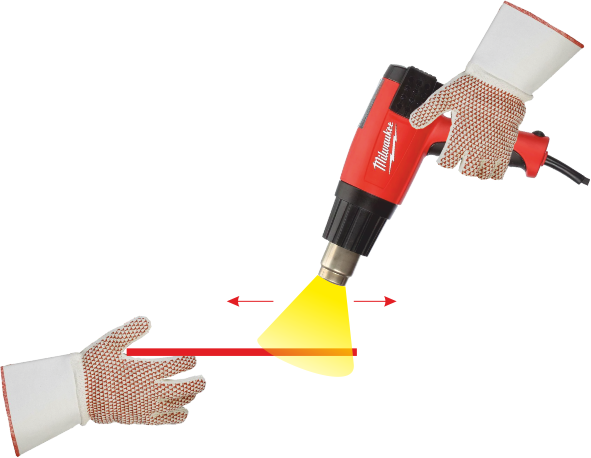

| If a small area of the thermoplastic is to be formed / shaped, simply heat the specific area with a heat gun. Take care to keep the heat gun moving over the area you want to form / mould. Holding the heat gun too close to the thermoplastic and in the same place, can cause the surface to ‘bubble’ and deform. |

| 1. USE A HEAT GUN TO ‘HEAT’ THE THERMOPLASTIC, IN THE AREA TO BE FORMED. WEAR HEAT RESISTANT GLOVES. |

|

| 2. PRESS THE PLIABLE / FLEXIBLE PART OF THE THERMOPLASTIC OVER THE MOULD AND HOLD IT IN POSITION. |

|

| 3. WHEN THE THERMOPLASTIC IS COOL, HAND PRESSURE IS REMOVED AND THE ‘PLASTIC’ WILL STAY IN THE SHAPE OF THE FORMER. |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

|