V.Ryan © 2020

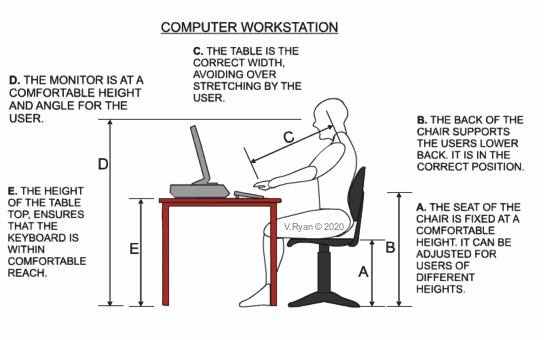

Ergonomic workstations should include consideration of the following:

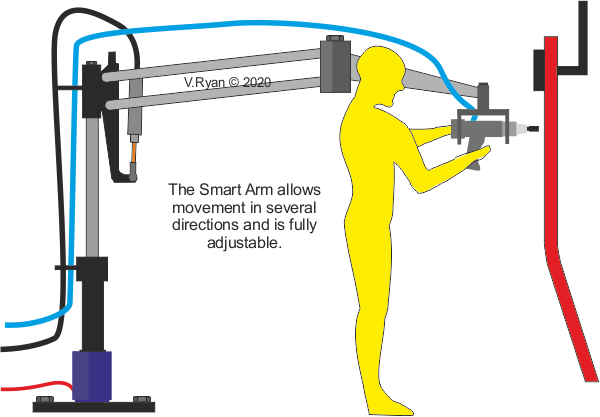

It may be necessary to adapt each work space, to suit a variety of individual operatives. This includes their working heights and how they stretch, to reach components / parts.

Ergonomic workstation design, recognises the spacial awareness of the operative and the range of vision required, for safe and efficient working. If an operative can easily see all the components he/she requires, this will reduce wasted search times, raising efficiency.

Reducing or limiting the unnecessary movement of the operative, will ensure he / she is more comfortable, promoting efficient working. Repetitive strain injuries often occur, due to uncomfortable working practices.

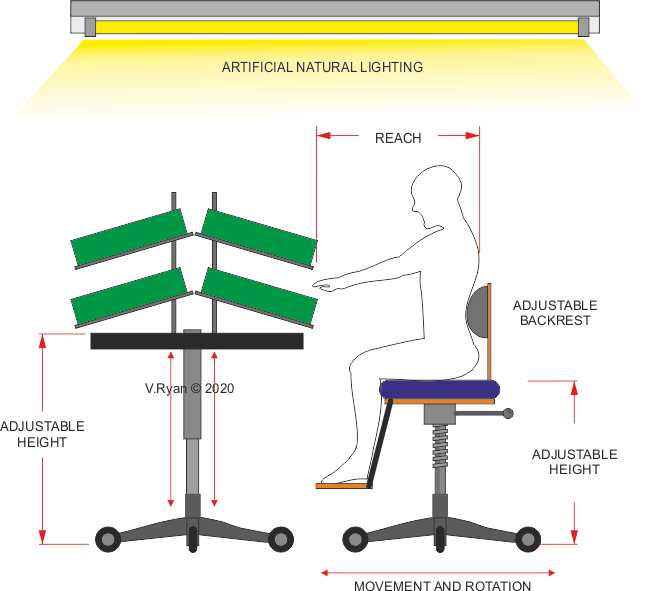

Good lighting is an important safety and ergonomic factor. The work area and everything in it / around it, should be visible. This will speed up the selection of components, by the operative, reducing eye strain, which could lead to tiredness and mistakes, or even accidents.

Seating, workbench and storage heights, should be adjustable, as operatives will vary in height and reach. The diagram above, shows that the seat and its backrest are adjustable. The workbench is also adjustable, through its hydraulic system.

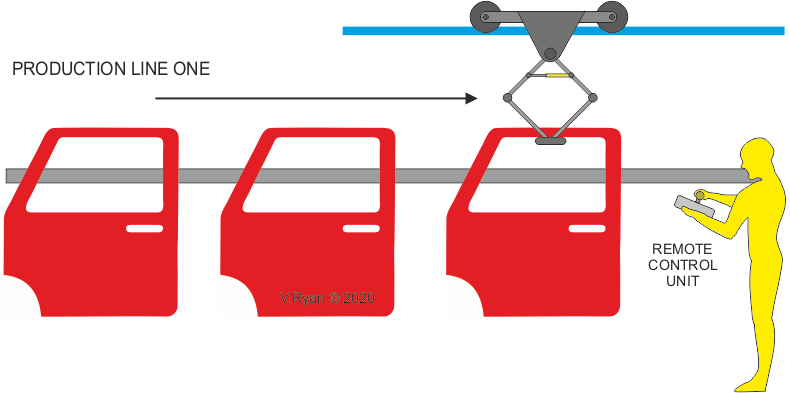

EXAMPLE: A typical conveyor and lifting system for a van manufacturer, is seen below. Production line one delivers doors to a workstation. They are transported along the production line, at the correct height, for the operator to handle. The operator controls a remote lift, which carriers each door to his / her workstation. The door is then attached to the van. There is no need at any time, for the operator to lift the door. This is an efficient and safe ergonomic system. Back and arm injuries are eliminated, time is saved and costs reduced.

BENEFITS FOR THE WORKER

Injuries are less likely.

Processes that put stress and strain on the body, are designed out, of each workstation. A workstation that is designed to promote good posture, also promotes efficiency.

Workstations are more efficient, as workers have higher levels of concentration.

Safety standards raised.

Employees feel more valued, due to the efforts my the company, to ensure a better workplace environment.

Increased productivity usually leads to higher pay.

A poorly designed workstation, leads to fatigued workers, who make mistakes and accident levels rise.

BENEFITS FOR THE EMPLOYER

Workers are less likely to be injured, therefore less time taken as sick days.

Litigation / legal action over repetitive strain injuries is less likely. Consequently, there is a reduction in compensation payments and health insurance.

Relations and mutual respect between the management and the production line worker, is improved.

Production levels and company profits rise.

Ergonomic productions lines are compatible with various forms of mass production (such as: Just in Time, Lean Manufacture and Computer Integrated Manufacture).

The development of ergonomic production lines is recognised as a commitment to good health and safety practices.