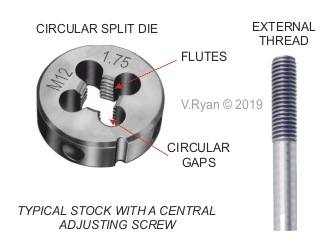

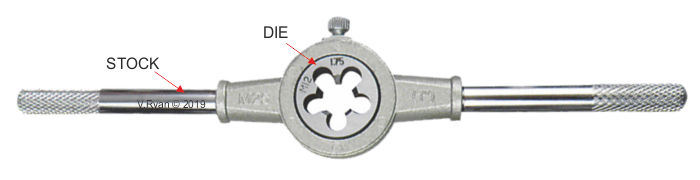

Cutting an external thread is achieved through the use of a die, held in a stock. Dies are manufactured from carbon steel or high speed steel, hardened and tempered. The stock is usually manufactured from mild steel. The most common form of die, is the ‘circular split die’, seen opposite. The flutes of the die, produce the ‘cut’ in the material being threaded, forming a thread. The ‘circular’ gaps allow chippings of waste material to escape from the die, preventing clogging of the cutting tool.

This may be obvious but, when threading round section steel, first select the correct diameter. For example, if an 8mm thread is required, the round section should be 8mm in diameter. The thread produced will be an M8 (metric 8) thread.

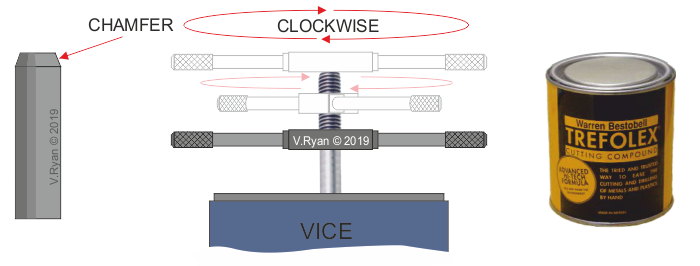

File a chamfer at the end of the round section steel. This will help start the thread, when using a die and stock. The chamfer can be created more accurately on a centre lathe, if one is available.

Use cutting compound when cutting the thread, applying it to the steel before cutting begins. This will ensure that the process is smoother and gives a ‘sharper’ thread.

Select the correct die. If an M8 thread is needed, then ensure that this is stamped / etched on the surface of the die. The die should be placed in the stock, with the wider side facing down at the steel to be threaded.

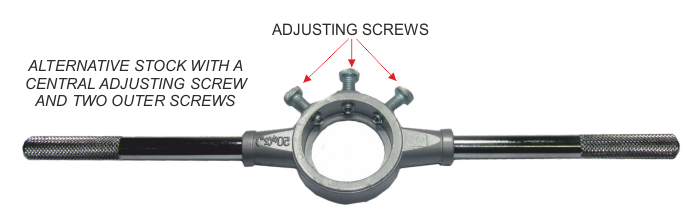

The centre adjusting screw should be tightened, widening the die slightly, as well as holding it firmly in the stock. Widening the die, makes initial thread cutting a little easier.

Ensure the round section steel is vertical in the vice (at 90 degrees).

Place the die on the round section steel, keeping it parallel with the vice. Add a little pressure and turn the stock in a clockwise direction. The first couple of ‘turns’ of the die are critical. If the stock is not parallel to the vice, a drunken thread will result. Stop once the die begins to cut the first couple of threads and check that the stock is still parallel to the vice.

Continue to rotate the stock in a clockwise direction. Once the thread has been started, for every clockwise rotation, rotate the stock in an anticlockwise direction, for half a turn. This clears away any steel chippings, from the die.

Thread cutting can continue until the correct length is been achieved.

Remove the stock and die from the thread by rotating it in an anticlockwise direction, effectively unscrewing it from the steel.

Untighten the centre adjusting screw and then tighten the two outer adjusting screws. Run the die down the thread a second time, as this will finish the thread accuratey.