| CLICK HERE FOR INDEX PAGE |

| |

| THE TRADITIONAL F-CLAMP |

V.Ryan © 2023 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

| |

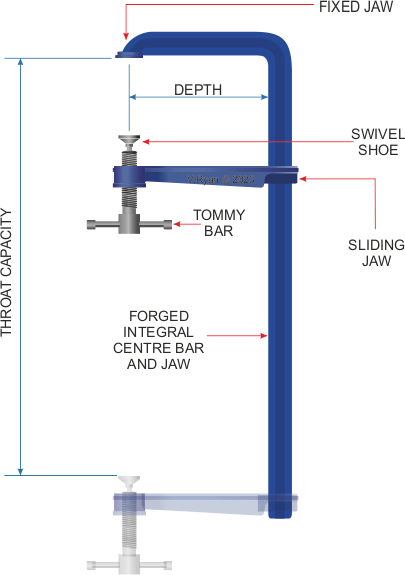

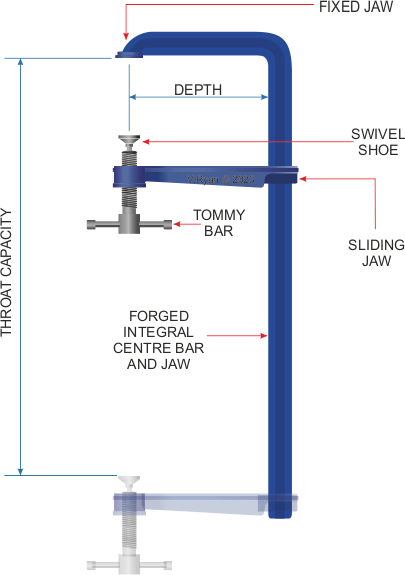

F-clamps, resemblance the letter ‘F’ (hence their name) and are also known a bar clamps. They have a similar function as G cramps, but they have a much greater ‘throat’ capacity. They are used for general clamping and are faster to use than sash clamps, but do not exert the same pressure, due to the nature of their design, especially their ‘depth’, as indicated on the diagram below.

The traditional F-clamp is made from a forged central bar (ensuring strength), which is angled at 90 degrees, forming the fixed jaw. The clamp also has a sliding jaw, which has a swivel shoe, which helps when clamping angled pieces of material. |

| |

|

| |

|

|

| |

| MODERN QUICK RELEASE F-CLAMP |

| |

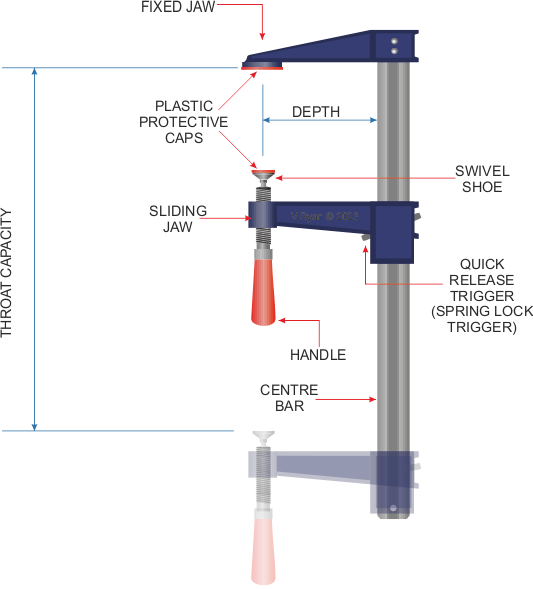

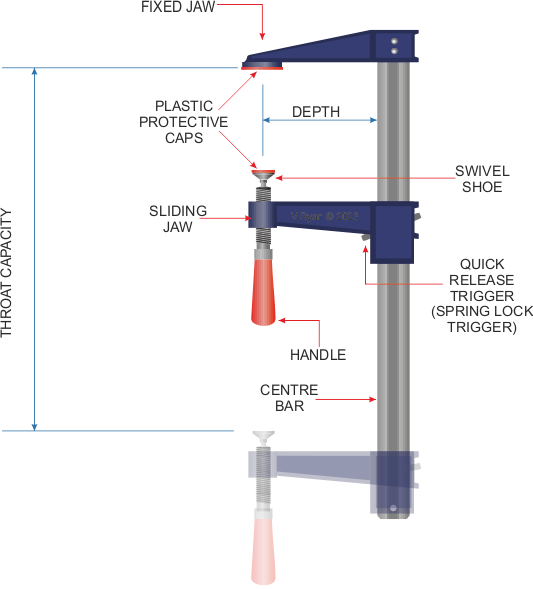

The modern F-clamp has a straight central bar, with a separate fixed jaw and sliding jaw. This means that they are slightly weaker than the traditional F-clamp, which has a forged central bar.

BThe ‘shoes’ of both jaws usually have plastic protective caps (which tend to come off eventually). They protect the surface of the materials being clamped. The modern F-clamp also has a sliding jaw. Some modern versions have a quick release trigger, allowing for a quick release of clamping pressure. A handle and the screw thread apply the pressure when turned. |

| |

|

| |

|

|

| |

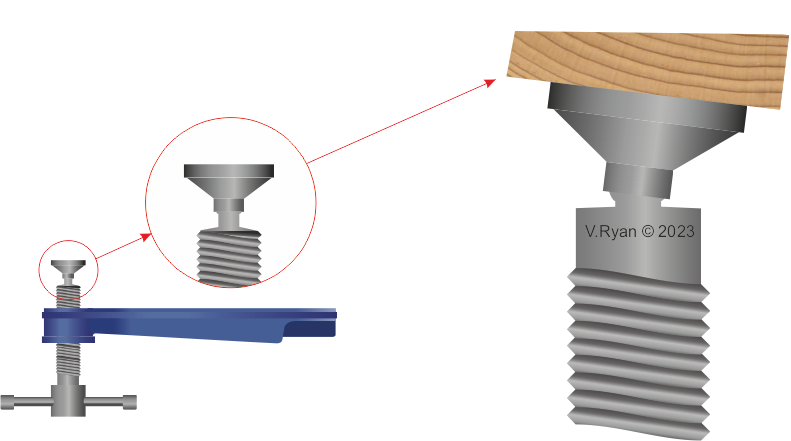

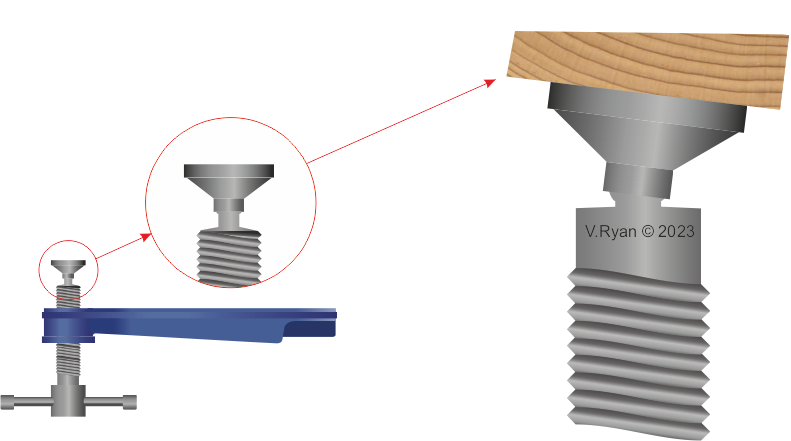

| Both types of F Clamp have a swivel shoe on the sliding jaw. This means that angled material can be clamped effectively. |

| |

|

| |

|

|

| |

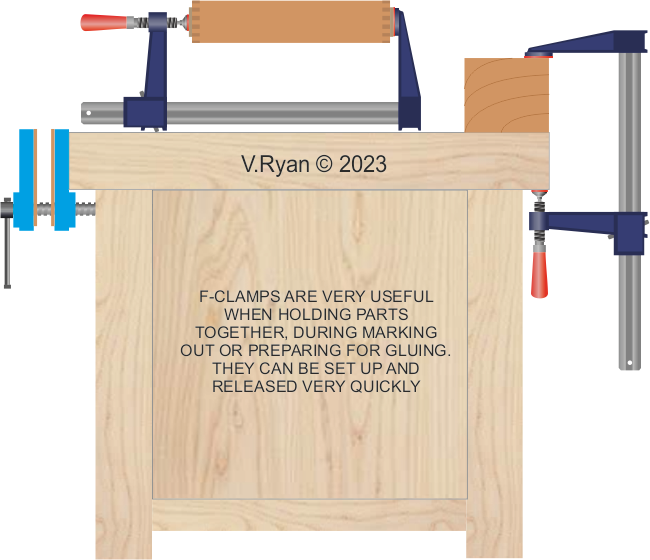

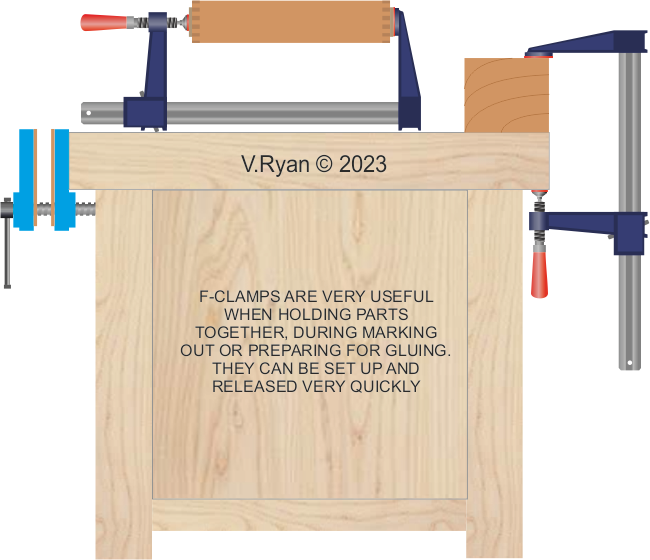

| TYPICAL USES OF THE F-CLAMP |

| |

|

| |

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|