| CLICK HERE FOR INDEX PAGE |

| |

| SPECIALIST HAMMERS - REPOUSSE HAMMER, BLOCKING HAMMER AND PLANISHING HAMMER |

| V.Ryan © 2019 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

A Rapousse hammer (also called a Chasing hammer|), is used for decorative metalwork, often in jewellery projects. It has an ergonomically designed handle, comfortable to hold. The head has a flat and rounded face, allowing a variety of detailed and decorative work, especially with non-ferrous sheet metal.

A Planishing hammer is used to ‘beat’ a patterned finish into the surface of nonferrous metals, such as copper and brass.

A Blocking hammer is the ideal choice, when ‘raising’ soft nonferrous sheet metal, to form a dish / bowl, as an aspect of beaten metalwork. |

| |

|

| |

|

|

| |

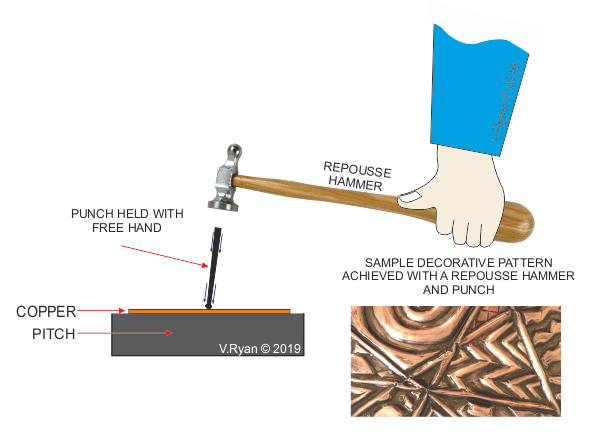

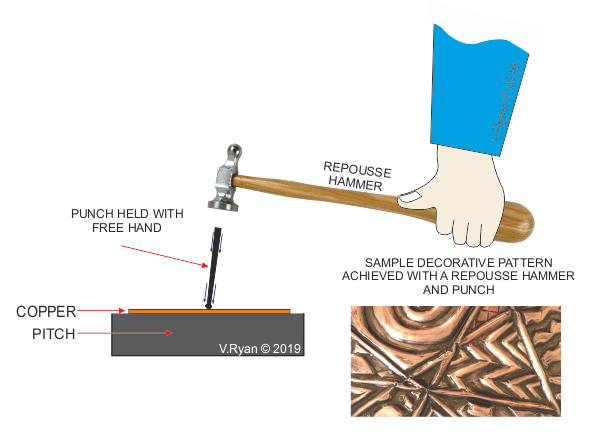

| EXAMPLE OF REPOUSSE WORK |

| |

The flat face of the repousse hammer, is being used to drive a ‘punch’ into the surface of annealed (softened) copper, producing a decorative pattern. The hammer can be reversed, so that the rounded face can be used directly onto the surface of the copper, producing a hammered pattern. Jewellers normally have a range of punches, capable of creating a variety of decorative patterns.

When ‘punching’, the copper is held securely in ‘pitch’. This is a solid material, that becomes soft when heated up. The copper is pushed into the surface and the pitch is allowed to cool. After the decorative work has been completed, the pitch can be heated up and the copper removed. |

| |

|

| |

|

|

| |

| USING A BLOCKING HAMMER |

| |

| The blocking hammer is used here, to form the initial shape of a dish / bowl, along with a hollowed out, wooden block. Jewellers have several of these blocks, with different sizes of hollows. They select the hollow most like the initial shape they want to form. |

| |

|

| |

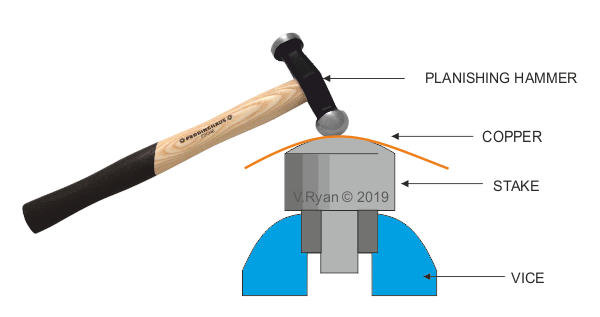

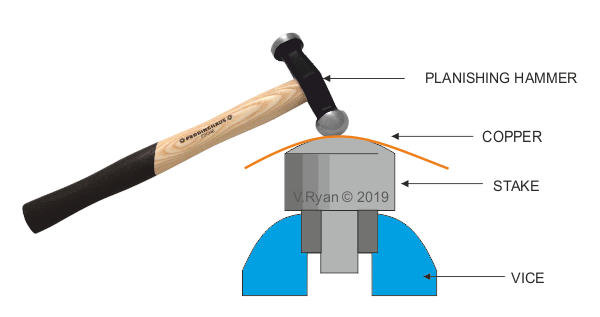

| EXAMPLE OF PLANISHING WORK |

| |

| After using a blocking hammer to form the initial shape of the dish, a planishing hammer is used to form a more accurate ‘dish’. A planishing stake of the appropriate shape/form, is held securely in an engineers vice. |

| |

|

| |

|

|

| |

| For good results, both the face of the planishing hammer and the face of the stake, must be polished and without damage or even scratches. |

| |

|

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|