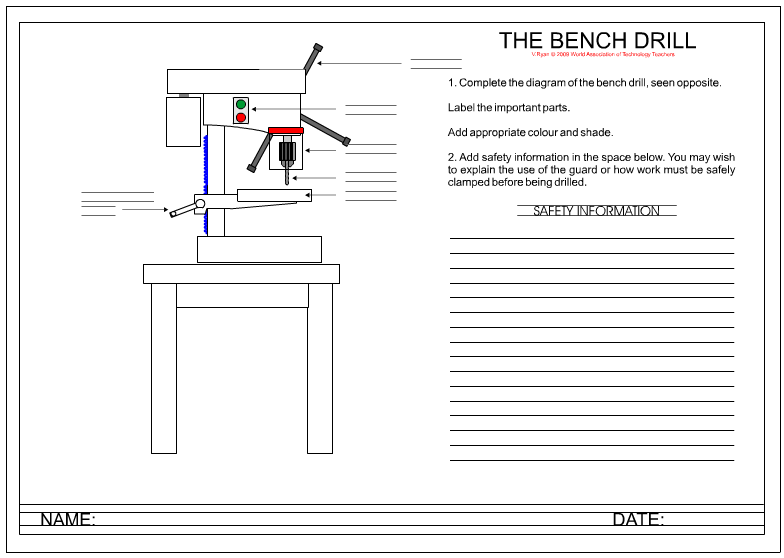

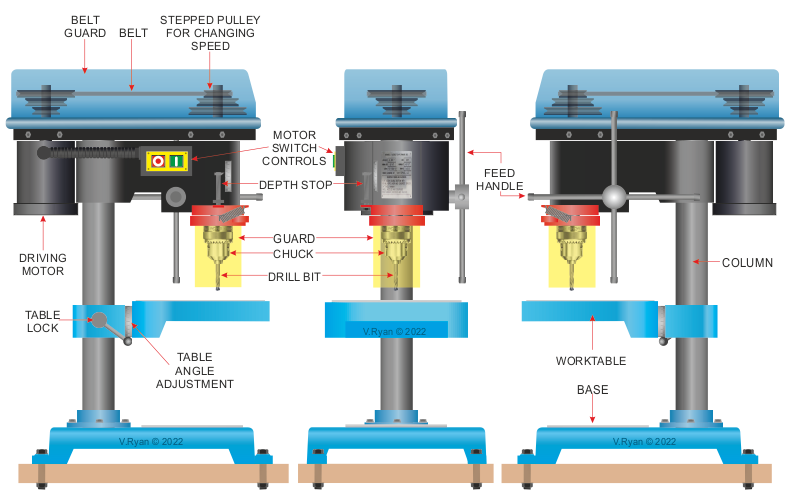

The on and off buttons are found on the left hand side of the machine and the handle controlling the movement of the drill on the right.

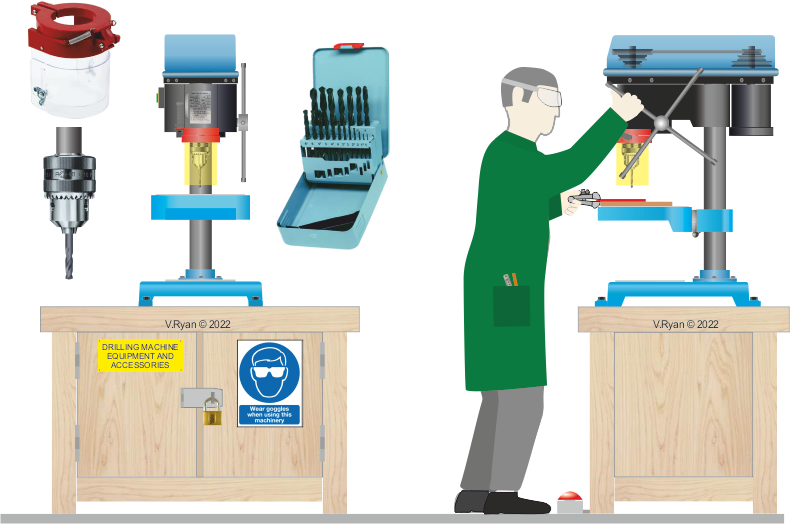

Most bench drills will also have a foot switch for turning off the drill.

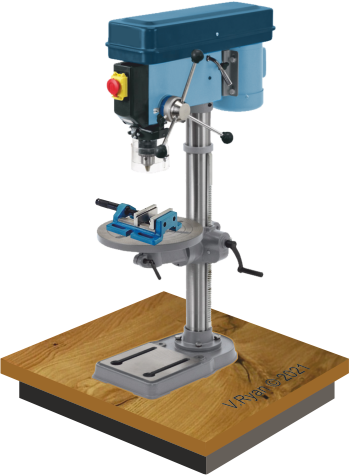

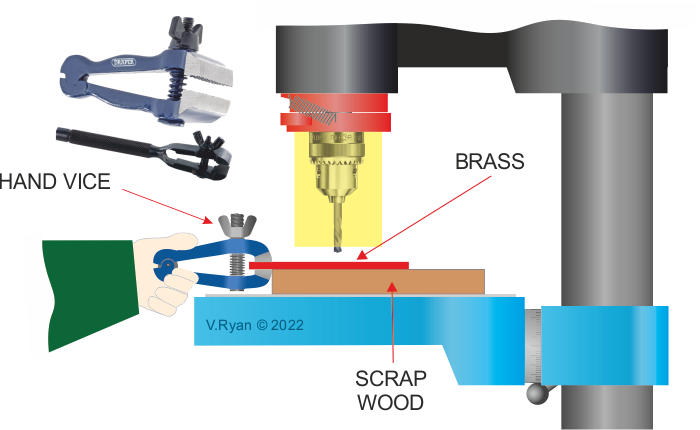

In the example the brass / metal is held in the vice and it also rests on scrap wood on the table.

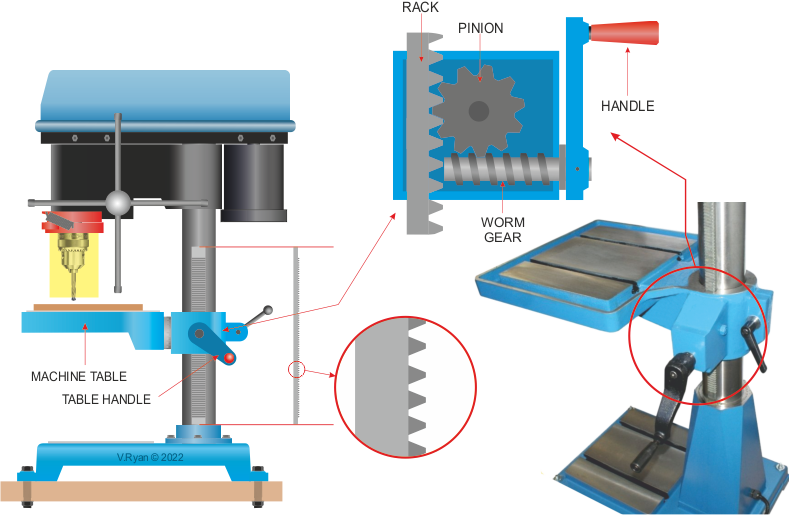

The height of the table is set by adjusting the table handle (see below). When drilling, the table should be moved quite close the the drill bit, so that the distance from the drill bit to the material is small.

Some machine drills have a rack and pinion system that allows height adjustment. The rack and pinion table adjustment, allows the user to lower or higher the machine table with ease. Simply rotate the handle to move the machine table up or down. Rotating the handle, rotates the worm gear. The worm gear meshes with the pinion gear, which rotates. The pinion gear meshes with the rack, moving the machine table either up or down.

The machine table is then locked in position.

The guard should always be used. This is the first line of defence if the material being drilled breaks or shatters. Wearing goggles is the second line of defence.