| CLICK HERE FOR INDEX PAGE |

| |

| THE JEWELLER’S TORCH |

V.Ryan © 2021 |

| |

|

|

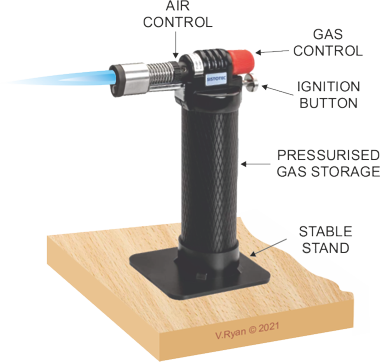

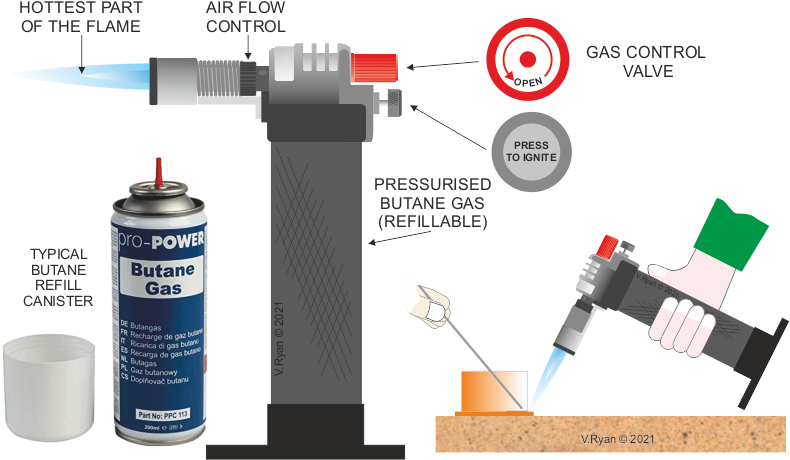

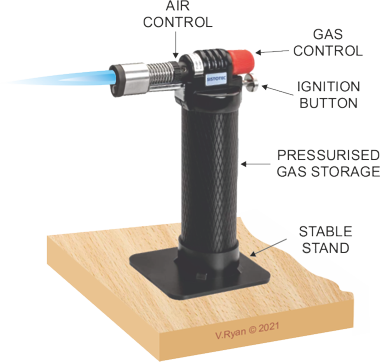

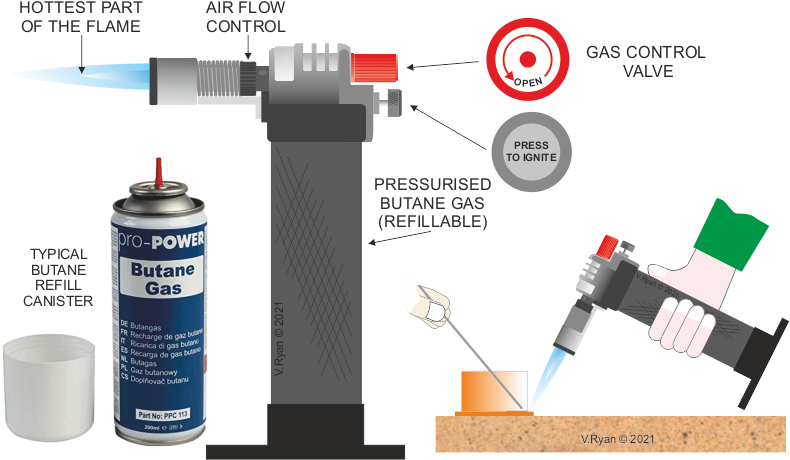

This is a modern Jeweller’s torch. It is operated by one hand and fuelled by butane gas. The torch can be refilled through a ‘refill valve’ in its base.

When in use, the focussed flame reaches a temperature of 1300oC, which means it can cope with most of the jewellers needs.

Butane torches are ideal for beginners and for general use. They are portable and easy to use.

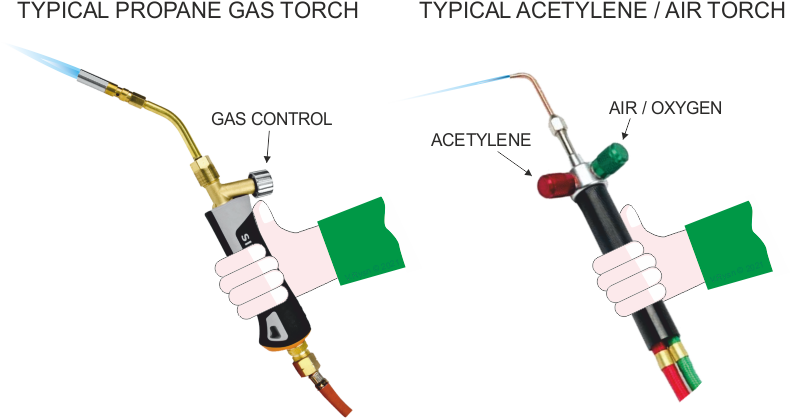

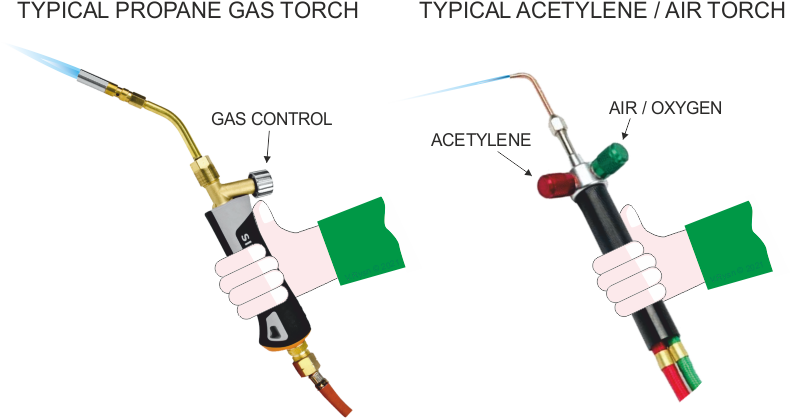

Acetylene / Air torches are also popular with jewellers. They depend on an acetylene tank. The gas mixes with air at the torch. They have a slight advantage, in that they have interchangeable torch tips, allowing for a wider variety of work.

Oxygen / propane torches are also popular, but they generally require a large gas tank. |

| |

|

|

| |

| To ignite the torch, open the gas valve slightly and press the ignition button. Then, increase the supply of gas by rotating the gas control valve. This controls the ferocity / intensity of the flame. |

| |

|

| |

|

| |

|

|

| |

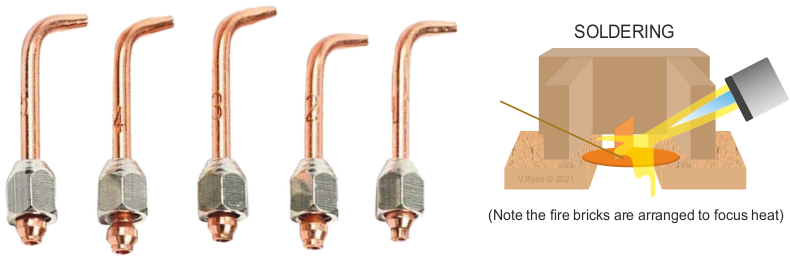

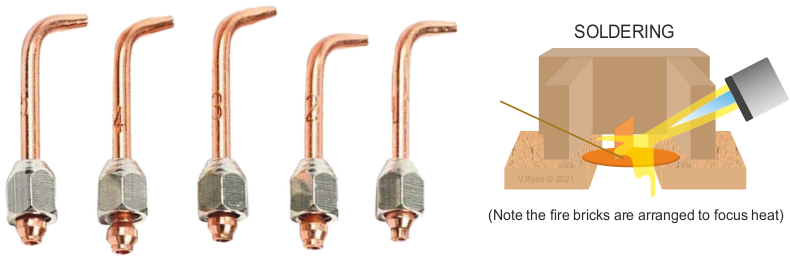

| Gas torches such as Acetylene / Air torches, are supplied with a range of torch tips (see below), which provide a range of flame lengths and heat output, suitable for a variety of metals and thickness. |

| |

|

| |

A gas torch is an essential ‘tool’ for a jeweller. Jewellers use gas torches to heat metal during the annealing process, to allow easy bending and forming of metal. As metal is worked by a jeweller it work hardens, which means during continuous working of the metal, it needs to be annealed several times.

When joining metals, the jeweller heats the metals, until they reach a specific temperature and then solder is applied. This fuses the two metals (or more) together permanently.

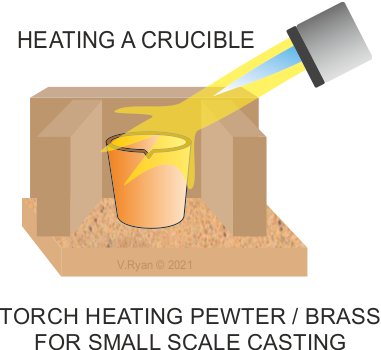

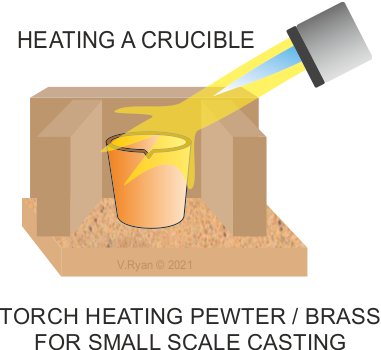

A torch can be used to melt some metals (for instance pewter), in a small jewellers crucible, ready for casting. Heating metals such as brass for casting, can be carried out on a brazing hearth. |

|

|

| |

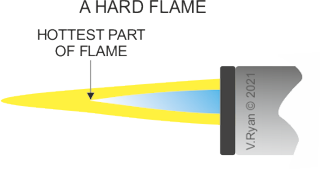

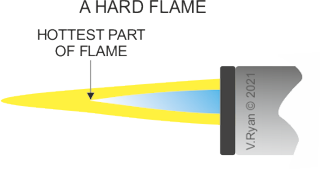

| Controlling the flame is critical during heat treatment. The shape / form / intensity of the flame, is determined by mix of air and gas. The flame shown opposite is called a ‘hard flame’. The flame is focussed and sharp. The hottest part of the flame is indicated on the image. For most jewellery work, a hard flame is too fierce, but in reality, it is the experience and skill of the jeweller, that determines the type of flame, used for different processes. |

|

|

| |

|

|

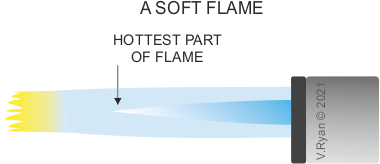

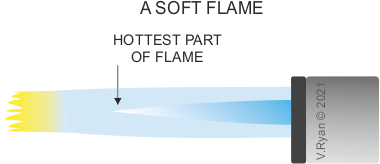

| This diagram represents a ‘soft flame’ and it is extremely useful to the jeweller. This flame is ideal for annealing metals because of its broad nature. It is also used for the majority of soldering. |

|

|

| |

|

|

| |

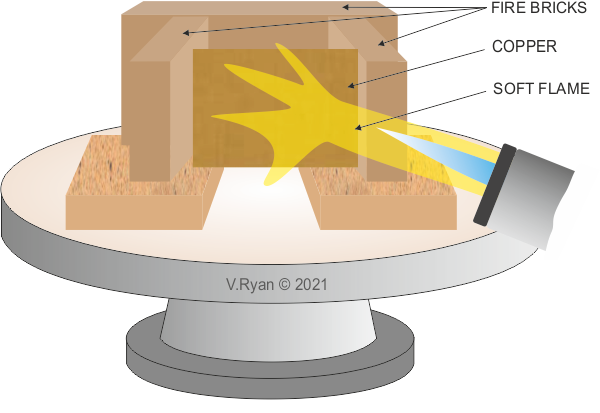

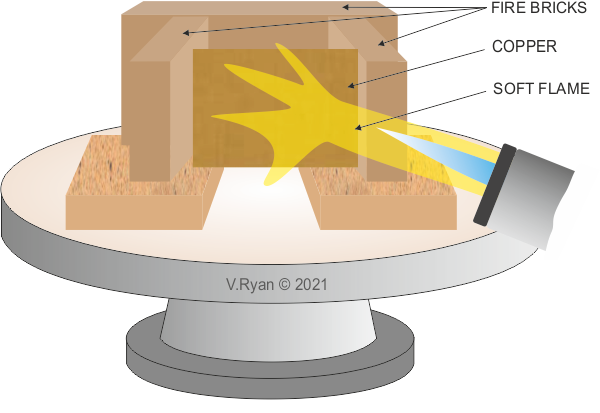

| When annealing a nonferrous metal such as copper, the copper is first cleaned. Then it is propped up by fire bricks (see below). The flame / heat is reflected back towards the metal by the bricks. A large soft flame is applied evenly across the copper surface. When the metal changes in colour to dark red (plum colour - between 500 and 600 centigrade), stop heating. The copper is then placed on a steel block and allowed to cool. The annealing process should leave the copper quite soft, easier to bend, form, shape and cut. |

| |

| Annealing brass is similar to copper, except the temperature is slightly less. |

| |

| When annealing aluminium, rub soap onto the surface. Heat the metal gently and when the soap turns black, remove the heat. |

| |

|

| |

| |

| CLICK HERE FOR JEWELLERY INDEX PAGE |

| |

|

| |

|