| CLICK HERE FOR INDEX PAGE |

| |

| THE MACHINE VICE |

| V.Ryan © 2022 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

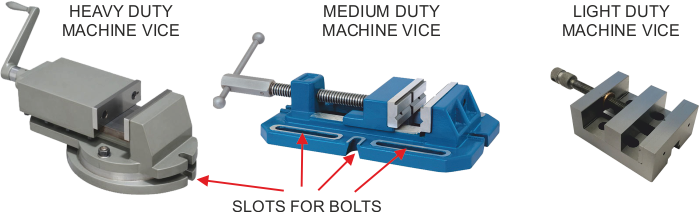

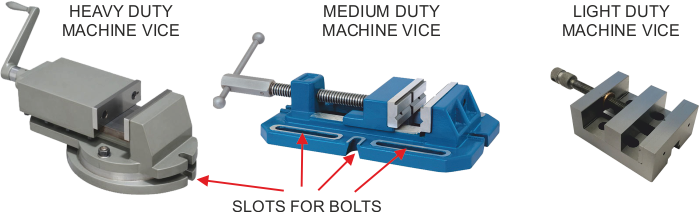

| Machine vices are supplied in a range of sizes, from light duty to heavy duty vices. The light duty vices, are designed for general drilling, such as drilling a hole on a pedestal drill. Heavy duty vices are designed for holding materials to be machined, for example, on milling machines or for drilling substantial holes in resistant materials such as steel. Both types of machine vice, tend to be supplied with a handle or a tommy bar, helping to apply leverage, when closing the jaws on the material. |

| |

|

| |

|

|

| |

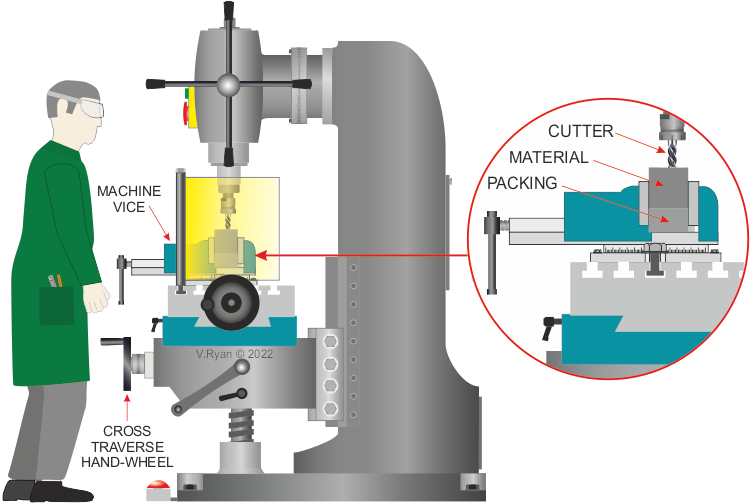

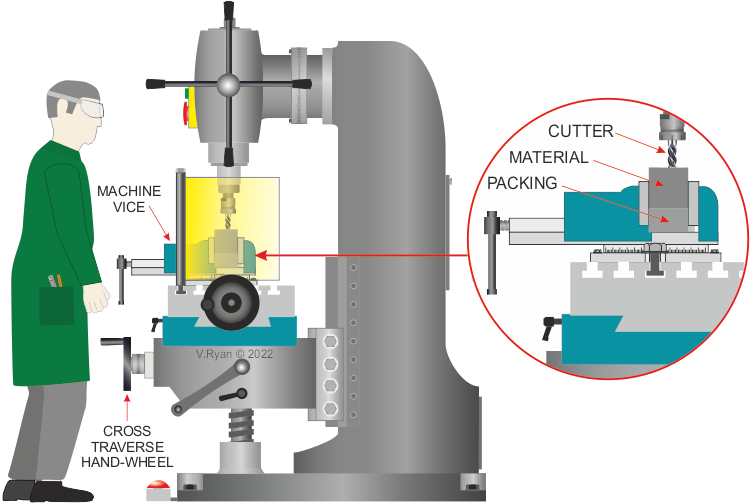

In the diagram below, the heavy duty machine vice, is bolted to the vertical milling machine.

The handle of the machine vice is first tightened by hand and then a wood / hide mallet (leather mallet) is used, to apply further force.

Machine vices are designed to hold substantial sizes of metals (steel etc...), so that they can be machined.

Notice the ‘packing’ under the material being machined. This supports the material, helping to prevent it moving during the machining process. |

| |

|

| |

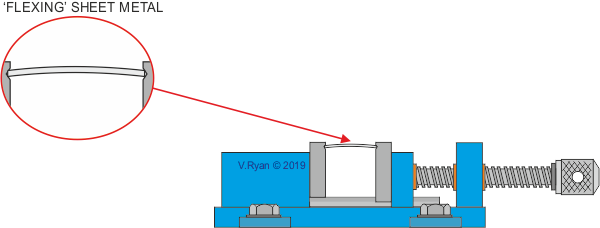

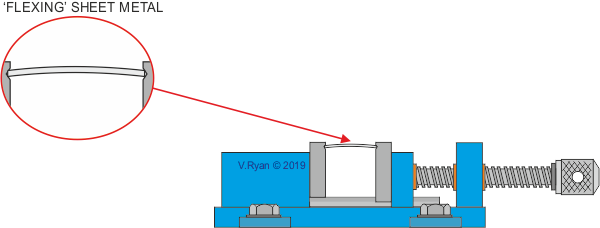

This diagram below, clearly demonstrates why a machine vice is not suitable, for holding sheet metal whilst drilling. The magnified view shows, the sheet metal bending under the pressure, applied by tightening the vice. If drilling goes ahead, the drill bit will slip from the correct position and it is likely that the metal will spin ‘dangerously’ out of the vice.

Packing underneath the metal is also vital, as this gives support, from the downwards pressure being applied to the drill bit. |

| |

|

| |

|

|

| |

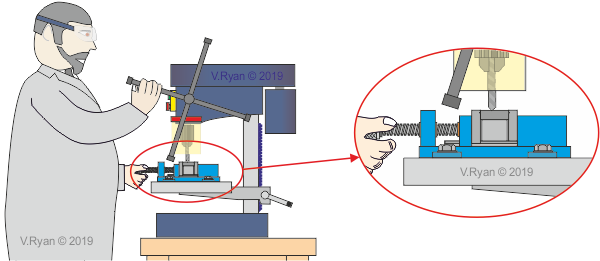

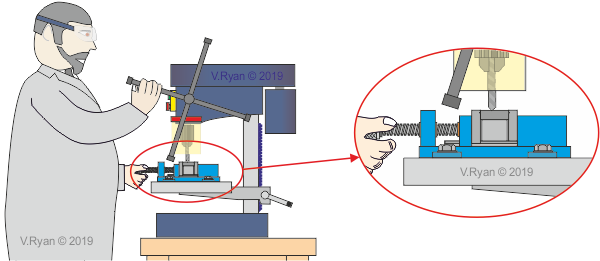

| The lightweight machine vice seen below, has been bolted to the table of the drilling machine. This means it is secured in the correct position and will not move, even if the drill bit ‘grabs’ the work. Depending on the material being drilled and the size of hole, it is usually safe to hold the vice in the hand (by the handle) and not necessary to bolt it to the drilling table. |

| |

|

| |

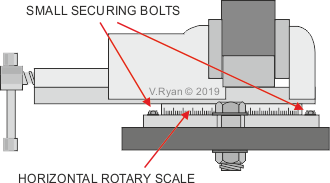

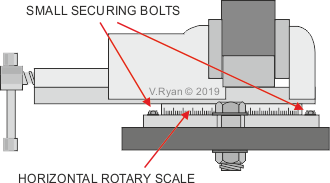

| This heavy duty machine vice can be set at a variety of horizontal angles. The ‘small’ bolts are loosened, allowing the main body of the vice to swivel 360 degrees on its horizontal axis. When the desired angle is reached, the bolts are tightened, holding the angle in position. |

|

|

| |

|

|

| |

|

|

This machine vice has both horizontal and vertical axis, alloying for a range of angles to be achieved. |

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|