| CLICK HERE FOR INDEX PAGE |

| |

| MANUALLY OPERATED - SHEET METAL FOLDING MACHINE |

| V.Ryan © 2019-2023 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

Folding sheet metal can be made easier, through the use of a manual folding machine. They are supplied in a range of sizes, determined by the by scale of folding taking place.

The folding machine seen opposite, is a typical manual folding machine and is desktop sized. The sheet metal to be folded, is seen on the bench, alongside the machine.

Folding machines favoured over folding bars, when the sheet metal is larger, than can be managed comfortably using folding bars. Also, accuracy of the final fold, can be virtually assured, with the folding machine

The operation of the folding machine is described below. |

|

|

| |

|

|

| |

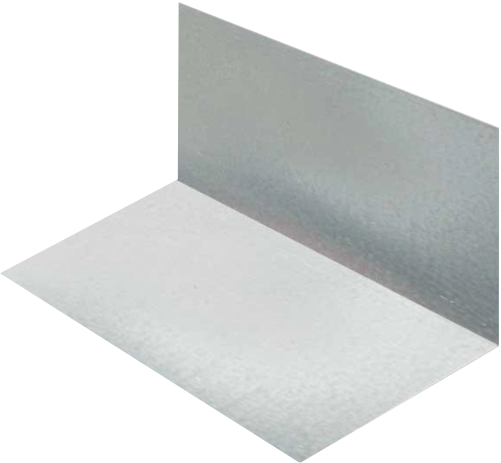

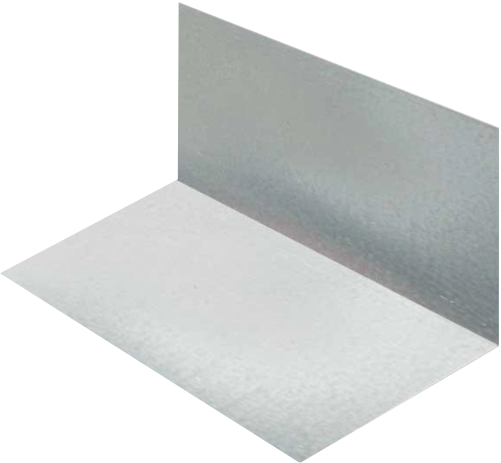

| TYPICAL EXAMPLE OF FOLDED SHEET METAL |

| |

| This is a typical example of a 90 degree fold, achieved through the use of the manual sheet metal folding machine. |

| |

|

| |

| The manual folding machine has a hinged based. The handle is screwed into the base, ready for use. It can be unscrewed after use, so that the machine is more compact to store. |

| |

The sheet metal to be folded, slides between the hinged base and the former and is secured in position by tightening the adjusting screws.

The handle is pushed upwards and the sheet metal is ‘force’ to the required angle. The adjusting screws are loosened and the sheet metal removed. |

| |

|

| |

|

|

| |

| The manual folding machine is ideal, when there is a need to fold the same angle many times, for instance during batch production. Folding bars are for smaller scale work and suitable for most school based sheet metal work. |

| |

| MANUAL SHEET METAL FOLDING MACHINE BOLTED TO A WORKSHOP BENCH |

| |

|

| |

|

|

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|