| CLICK HERE FOR INDEX PAGE |

| |

| THE PRECISION HAND MITRE SAW |

V.Ryan © 2022 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

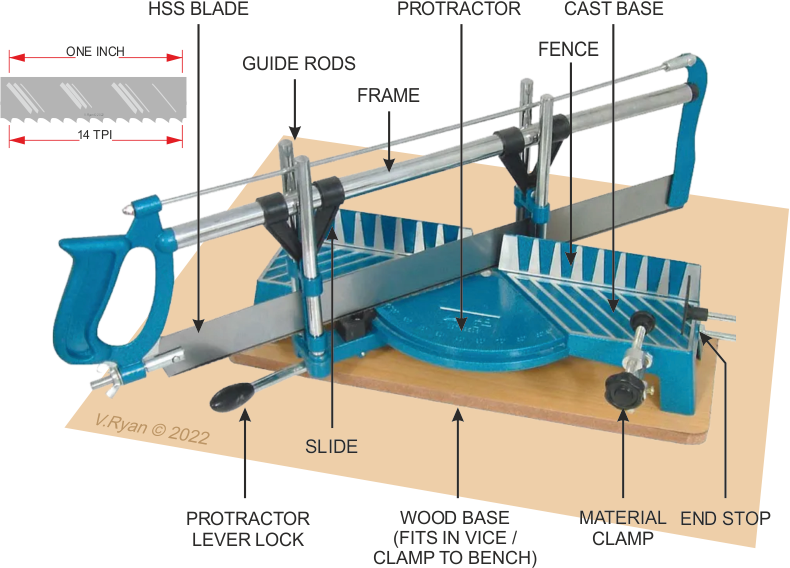

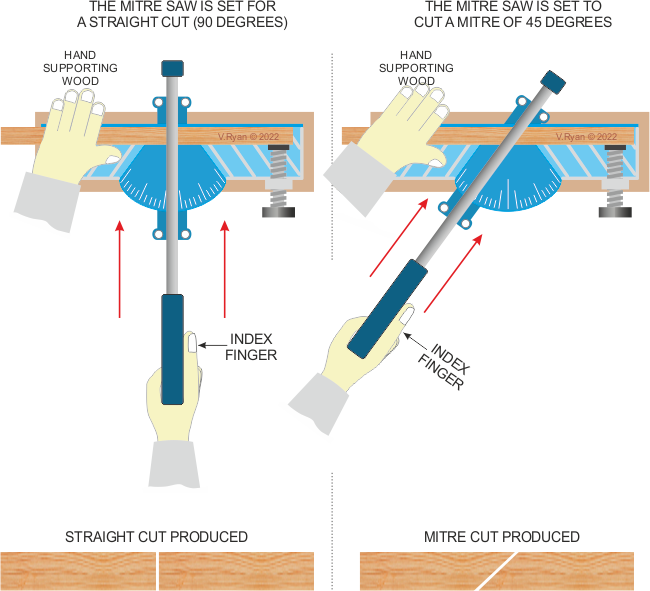

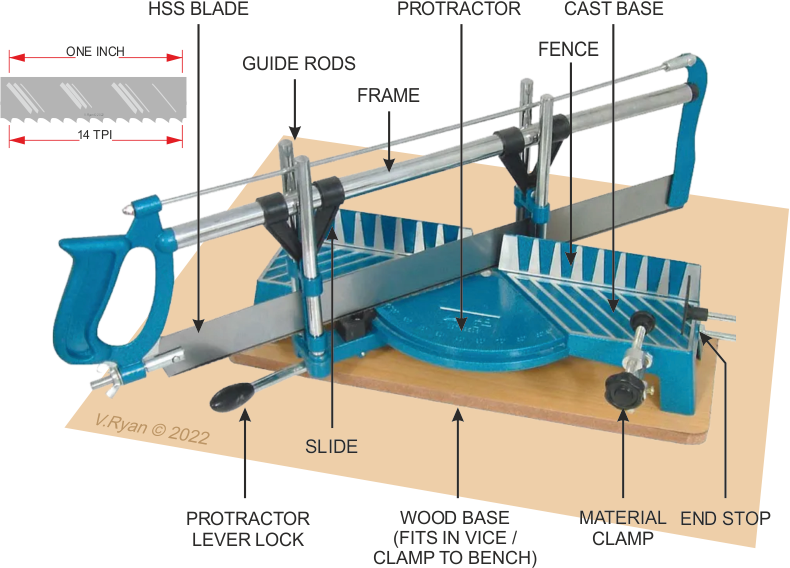

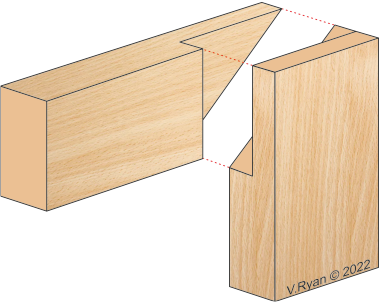

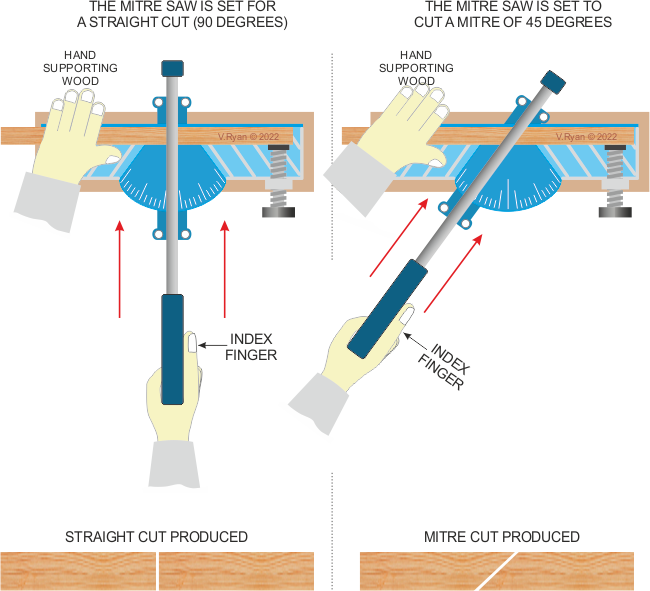

| The ‘precision hand mitre saw’ is extremely useful, especially when cutting angles. It is a lightweight adaptable saw, with a range of uses. It is ideal for cutting joints, such as the mitre corner joint. It can even be used to help cut halving joints. The most common type has a 550mm blade, with 14 TPI (teeth per inch). It also has an adjustable angle scale, a little like a protractor, that allows the blade to be set from -55 to +55 degrees. The ‘protractor’ has a number of preset angles, where the blade can be locked in position. It is important occasionally, to apply a little ‘light’ oil to the frame and slides, as this will aid a smooth cutting action and prevent jamming. |

| |

|

| |

|

|

| |

|

| |

| |

ADVANTAGES OF THE MITRE SAW

COMPARED TO OTHER HAND SAWS

A lightweight saw.

It can be secured to the bench, by holding it firmly by hand, or being held in a vice or G-cramped.

The saw has sturdy construction.

Angles are set easily, using the protractor.

People who struggle with a tenon saw when cutting angles, find the mitre saw easy to control and use.

Angles are cut accurately, first time.

This saw is a relatively cheap option, compared to other quality back saws. |

|

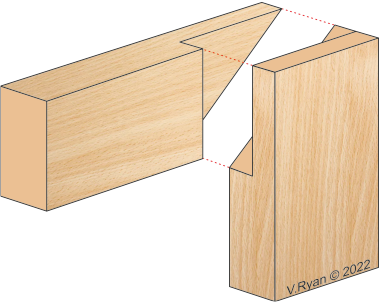

MITRE CORNER JOINT

EXAMPLE OF MITRE SAW WORK

|

| |

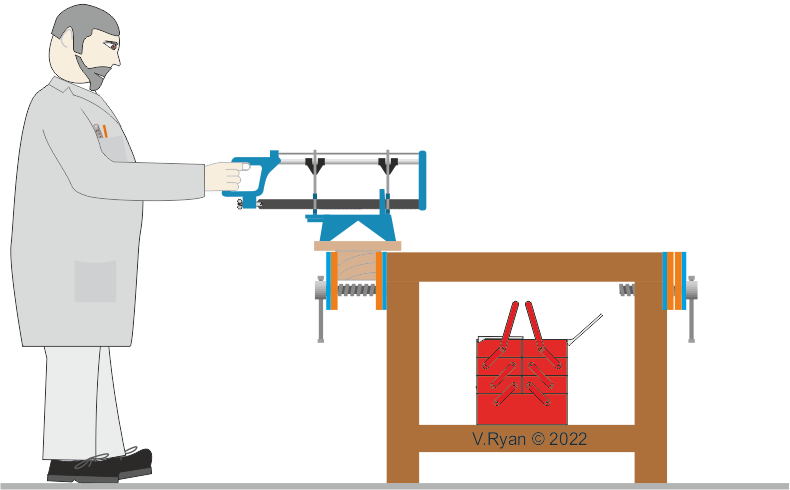

| USING THE PRECISION HAND MITRE SAW |

| |

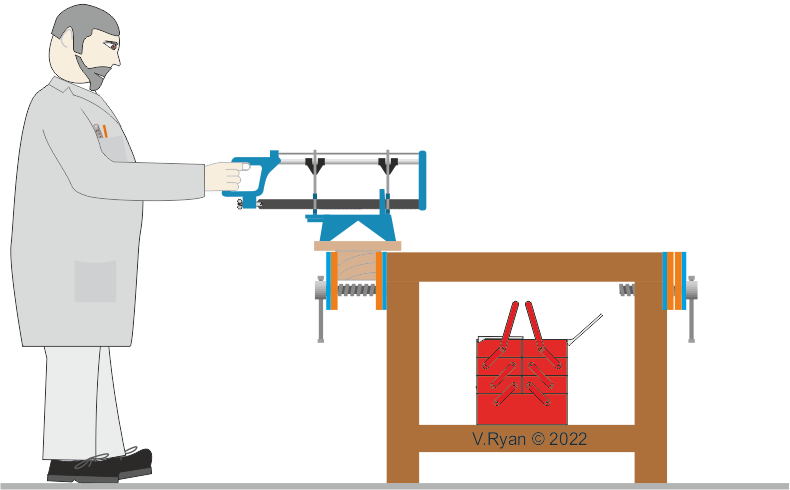

| The diagram below, shows the mitre saw being held in a vice. A block has been bolted / screwed to the mitre saw’s base and it is secured in the vice. This means that the mitre saw is not likely to work loose, during the sawing procedure. |

| The handle of the saw is held in the same way as a tenon saw. The index finger should point down the frame, ‘pointing’ in the direction of the cutting action. Smooth cutting strokes, provide the most efficient sawing. |

| |

|

| |

|

|

| |

|

| |

| This saw makes cutting angles and mitres, relatively easy. Marking out tools, such as a mitre square or sliding bevel may not be needed, because the blade / saw can be set to the correct angle, using the protractor. Once the angle is set, the saw is locked in place, using the protractor lever lock. The mitre saw is either held firmly in position on the bench surface, by hand, or placed in a vice, or it can be clamped to a work bench. |

| |

|

| |

|

|

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|