V.Ryan © 2023

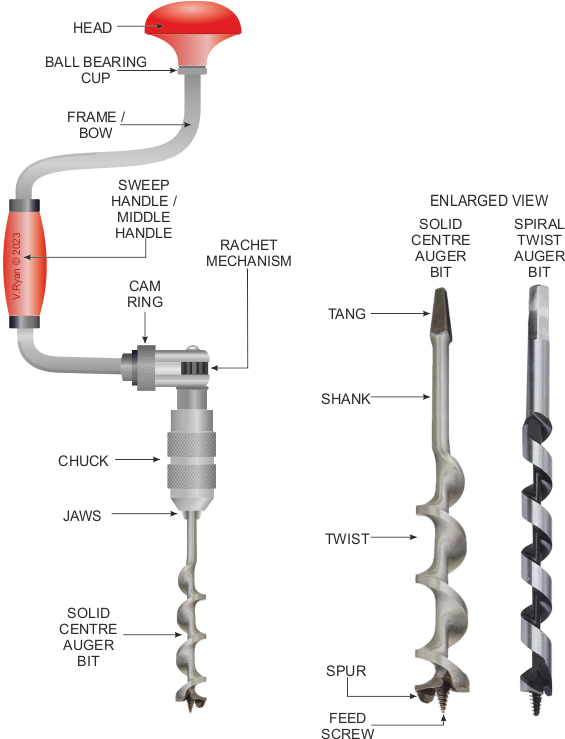

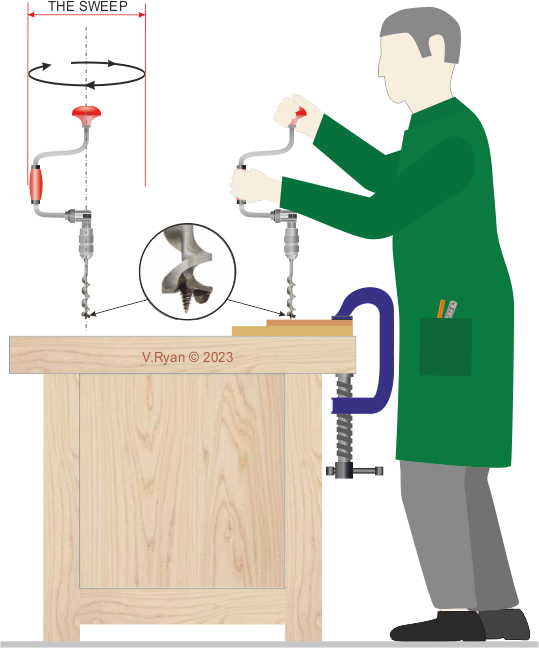

The ratchet brace is ideal for drilling holes, including larger diameters. One hand applies downward pressure to the ‘head’ (top handle), at the same time as the second hand rotates the ‘sweep handle’. The distance moved by the sweep handle, is simply called the ‘sweep’.

A clever ratchet mechanism, means that complete rotation of the sweep handle is not required (although preferred). This means the ratchet brace can be used in confined places, where full rotation is not possible.

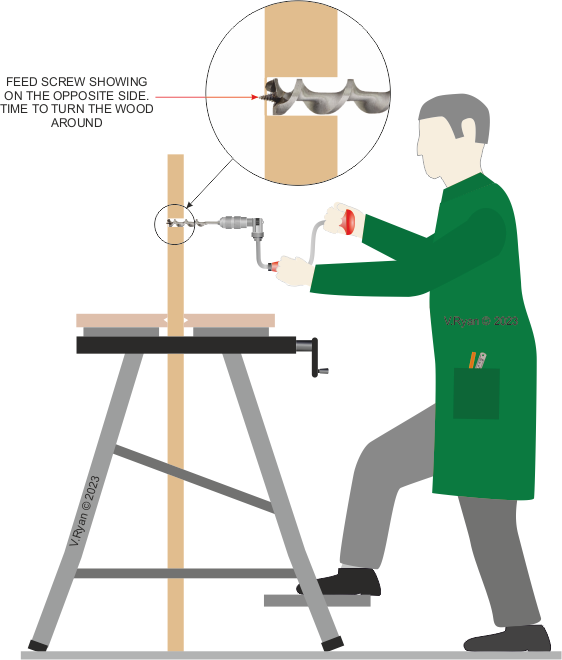

TIP - If a piece of wood is held vertically in a workbench:

Drill through the wood until the feed screw of the auger bit, shows through the opposite side and STOP.

Turn the wood round, clamp it in the jaws of the workbench. Place the feed screw of the bit, in the small exit hole already created and continue drilling.

This ensures a good, clean, finish, to the edge of the hole. Drilling all the way through the wood in one go, can lead to the auger bit ‘bursting’ through the opposite side, causing splits.