| CLICK HERE FOR INDEX PAGE |

| |

| THE RIPSAW AND RIPSAWING |

V.Ryan © 2022 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

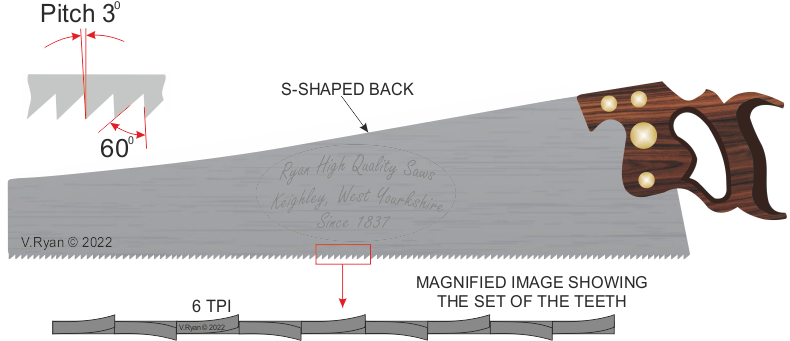

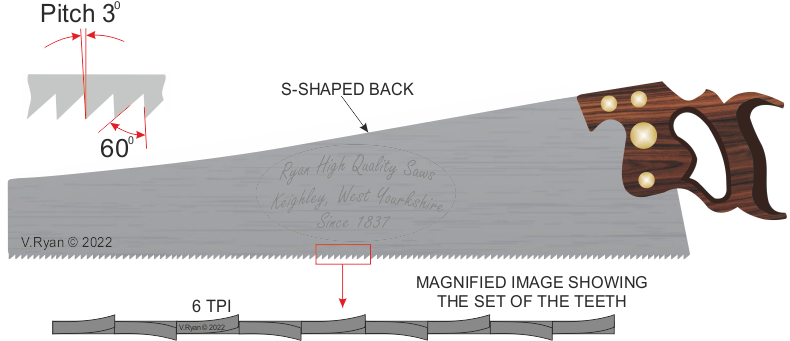

The ripsaw is one of the largest saws found in a workshop. The saw is designed to ‘saw’ wood along the length of the grain and consequently it usually has six teeth per inch (6TPI). On appearance, it is a saw with a coarse set of teeth.

Quality ripsaws have an ‘s’ shaped back, which serves to lightening the saw and improve it’s visual appearance. This type of saw is usually 650mm in length. |

| |

| The ‘set’ of the teeth (alternate teeth bent left and then right) allows clearance, so that waste chippings can escape and that they do not lead to the jamming of the saw, during cutting. |

| |

|

| |

|

|

| |

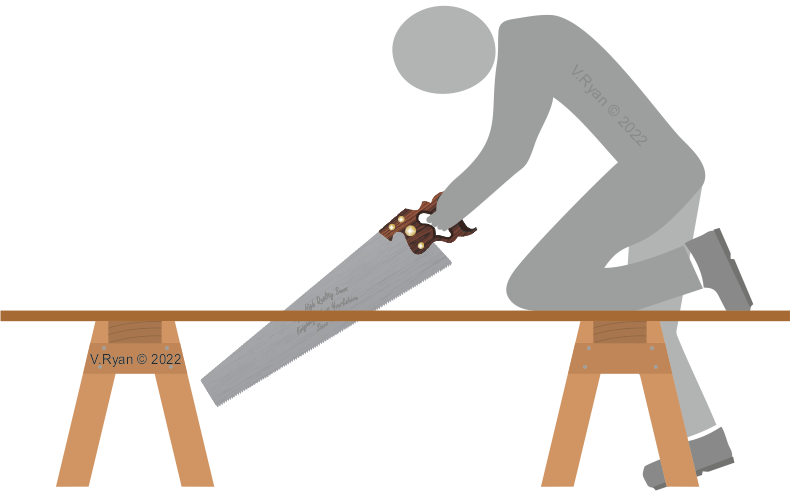

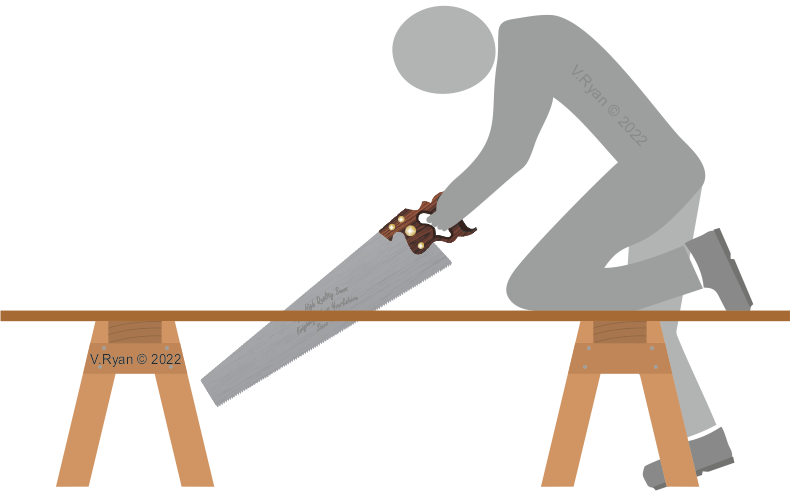

| Supporting long lengths of wood requires the use of at least two sawhorses (sometimes called trestles). The user places the wood across two sawhorses and applies pressure with one knee, whilst at the same time sawing along the grain. The free hand can be used to hold down the wood. As the wood is sawn along its length, the saw horses are moved to ensure the best support. |

| |

| TIP: If the saw blade starts to jam or the sawing action becomes difficult, due to the friction of the saw blade against the wood, rub a wax candle along its length and start sawing again. This should ensure that the sawing action, is smooth and continuous. |

| |

|

| |

|

|

| |

|

|

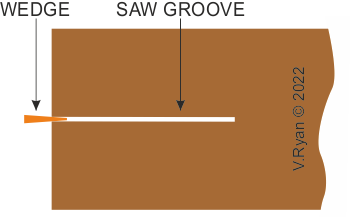

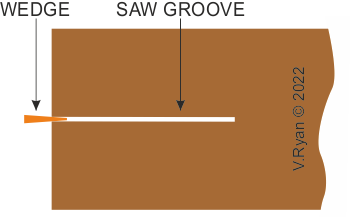

When ripsawing a long length, the groove left by the saw can begin to ‘clamp’ the saw blade. This makes sawing very difficult and sometimes impossible.

To counter this problem, tap a small wedge in the groove, at the starting point. This holds the groove apart, allowing the blade to cut, without creating too much friction, which can lead to jamming. |

| |

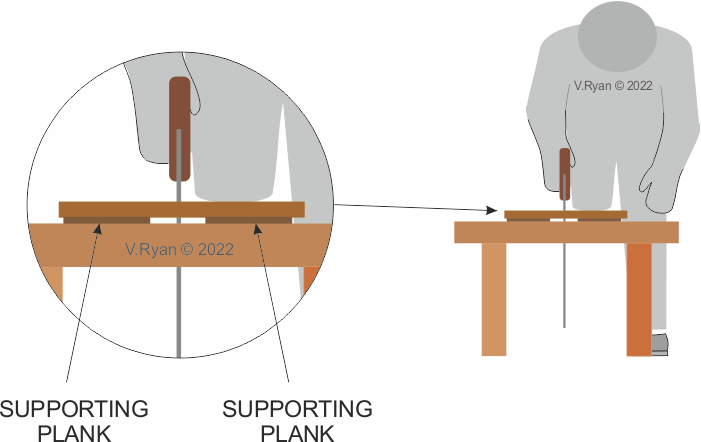

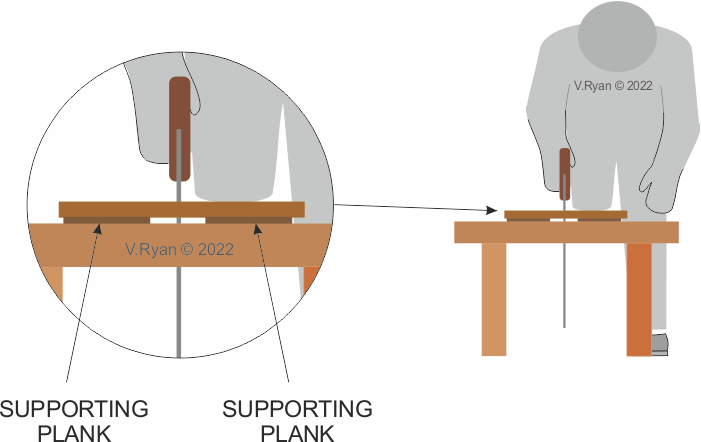

| If the wood / board being ripsawn is quite wide, it is advisable to support it with two ‘planks’. The planks are placed either side of the saw cut. This techniques helps to prevent the wood / board being cut, from bending / flexing, ensuring an easier cutting process. |

| |

|

| |

|

|

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|