V.Ryan © 2021

| CLICK HERE FOR INDEX PAGE |

| CNC METAL SPINNING |

V.Ryan © 2021 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

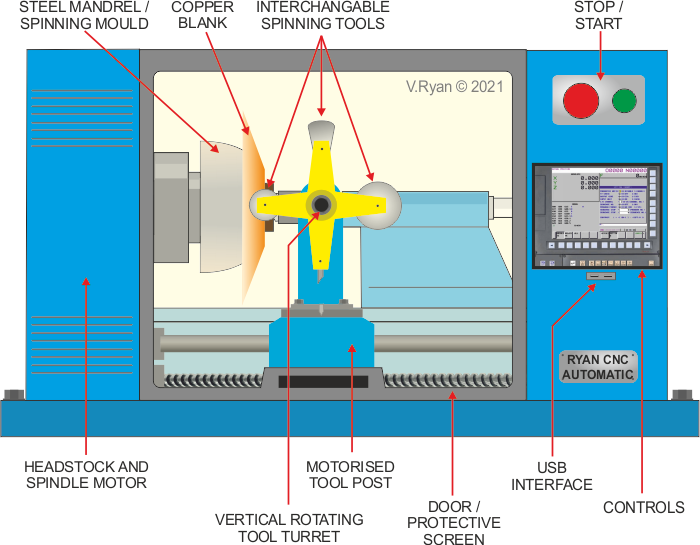

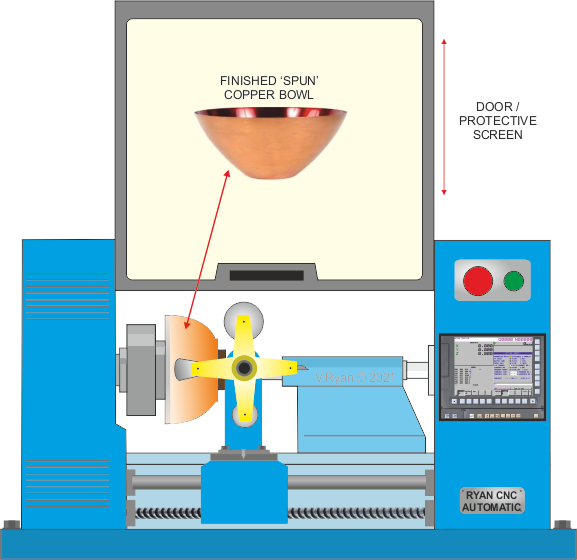

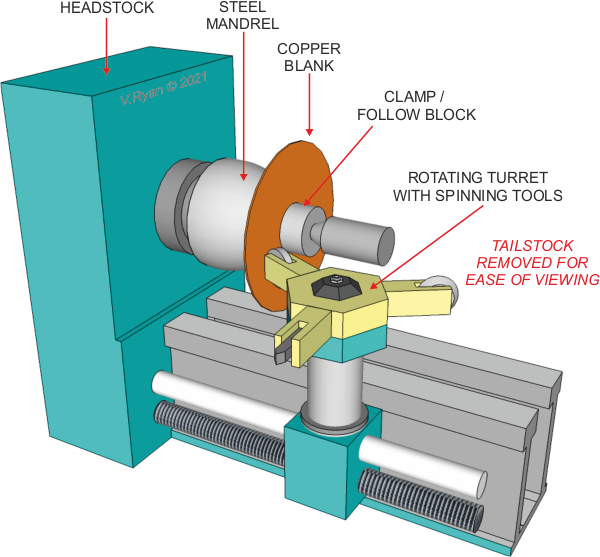

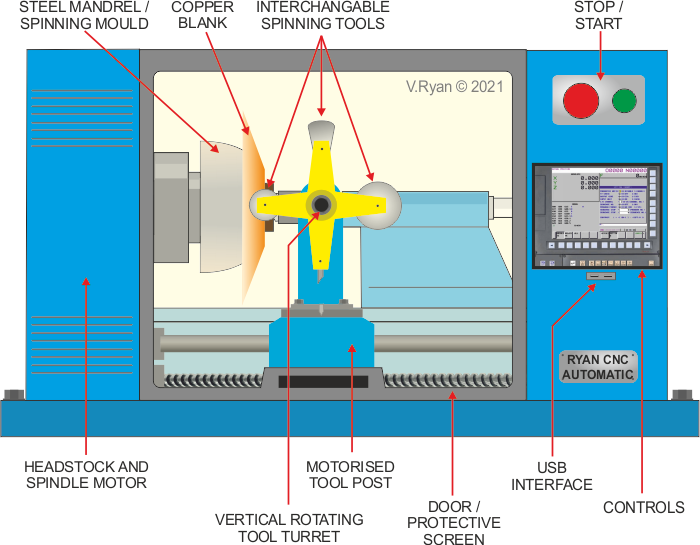

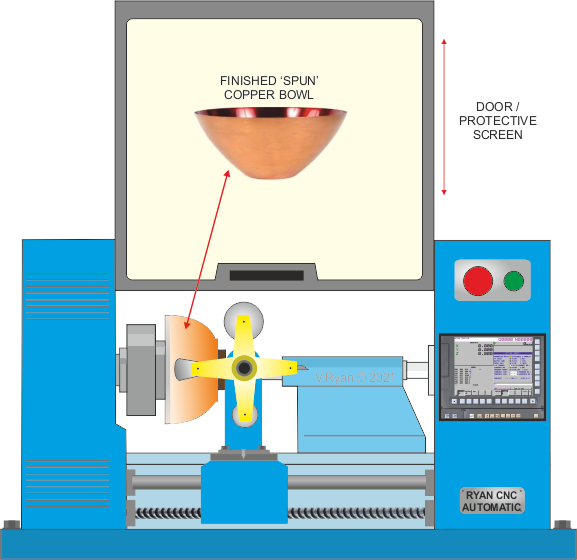

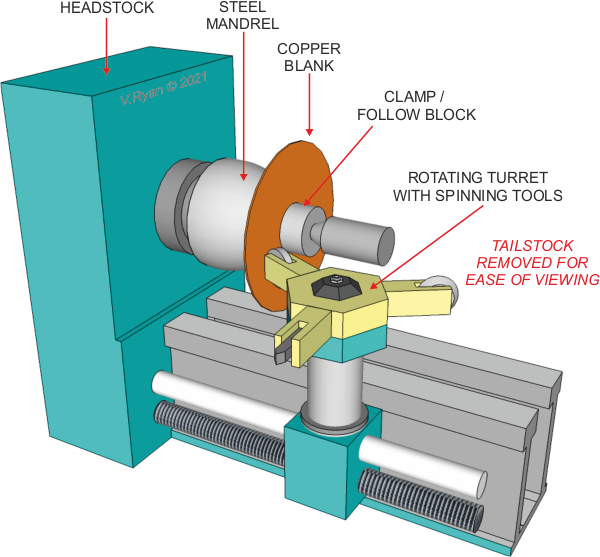

| CNC metal spinning is an automated process, requiring little handling by the machine operator. The operator sets up the sheet metal blank and the CNC machines does the rest. The operator acts as a supervisor and makes adjustment to the machine tools, when required. The spinning tools are set up on a rotary head. This rotates the varies tools, as and when they are required. |

| CNC metal spinning has several advantages over the manual process. It is a much faster process, as tool changeover is automatic. Shapes that are difficult or even impossible to achieve by manual spinning, can usually be completed on a CNC machine. Large scale production can be carried out, with the operator simply changing the blanks, each time one is finished. Automation is cost effective, when a large number of the same design / product / component, are being manufactured. |

| CNC metal spinning also has some disadvantages, compared to manual spinning. The CNC machine initially takes longer to setup and needs programming to complete the spinning process. This means that small production runs or even the manufacture of a single piece, are not cost effective. The CNC machine is far more expensive, than the cost of converting a traditional lathe, for manual spinning. Products manufactured through CNC spinning, are not hand made and cannot be labelled as such. |

|

| VIEW WITH GUARD OPEN |

|

| CNC SPINNING MACHINE WITH HORIZONTAL ROTATING TURRET |

|

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

|