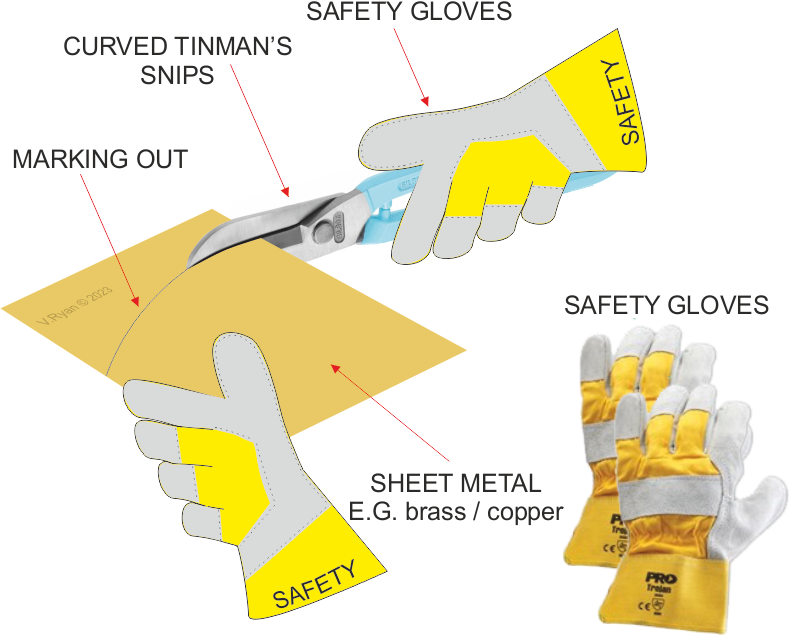

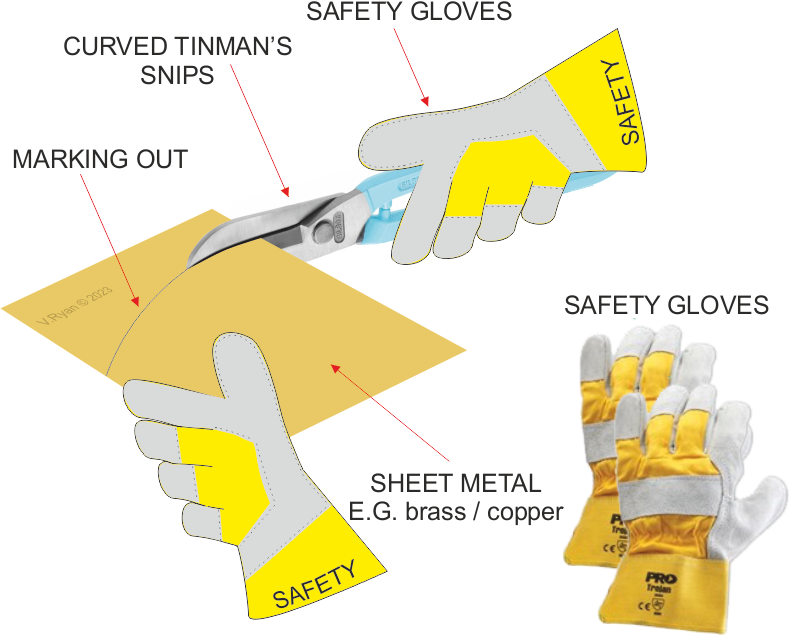

Care must be taken, as very sharp edges are produced when cutting takes place. Safety gloves are essential.

| CLICK HERE FOR INDEX PAGE |

| TINMAN’S SNIPS |

| V.Ryan © 2019-2023 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| Tinman’s Snips are ideal for cutting ‘thin’ sheet metal, such as aluminium, copper and brass. They are operated by hand and are normally used after the sheet metal has been softened through the annealing process. |

|

| HINT: Consider securing the tinman’s snips in the vice, feeding the sheet metal into the jaws. This can make the cutting process easier. Also, consider protecting your hands by wearing safety / leather gloves. The edge of sheet metal can be extremely sharp or have sharp burrs. Using leather gloves is a commonsense solution to possible accidents. |

|

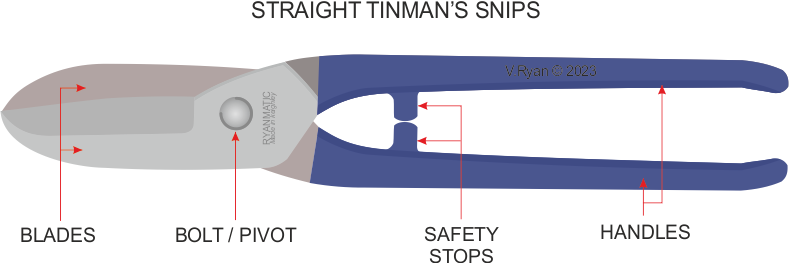

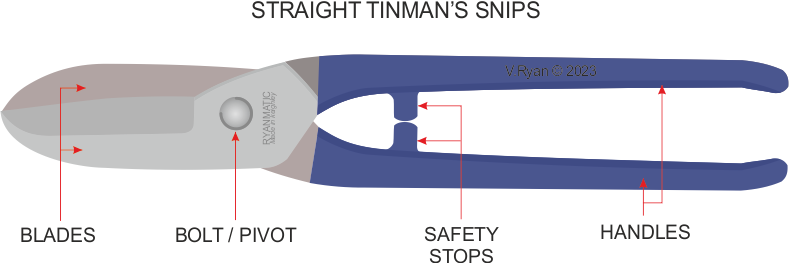

| Straight tinman’s snips are ideal for cutting ‘straight’ lines. The straight jaws act as a guide, helping to cut in a straight line. |

|

|

| CURVED TINMAN'S SNIPS |

| Curved tinman’s snips are for cutting curves. The curved ‘jaws’ / cutters, help the user to follow a curved guideline. |

|

| As the jaws of curved tinman’s snips, close, their shape helps the user follow the marking out. However, the tighter the curve, the more control is required by the user. Care must be taken, as very sharp edges are produced when cutting takes place. Safety gloves are essential. |

|

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

|