| CLICK HERE FOR INDEX PAGE |

| |

| TOOLMAKERS’ CLAMP |

| V.Ryan © 2019-24 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

|

|

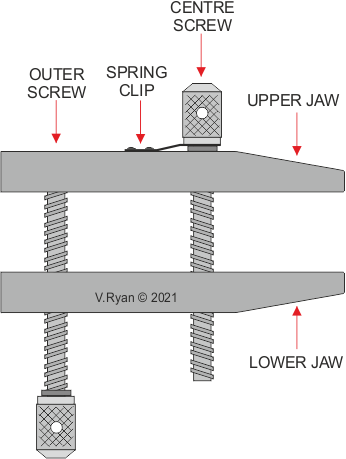

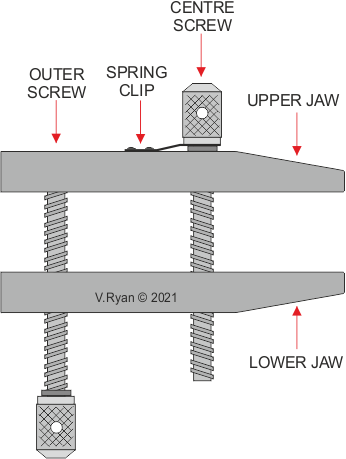

The toolmakers’ clamp has a number of uses. It can be used to clamp materials together, to enable marking out and even during welding. Toolmakers’ camps are sometimes used to secure materials during drilling, although often, more capable clamps are available for this process.

The jaws are made from mild steel that have been case hardened. The adjusting screws(centre and outer screws), are knurled because they are ‘adjusted’ by hand. Every effort should be made to keep the jaws parallel to each other, when clamping materials. If the jaws are not parallel, when clamped, the screws can be damaged (bent), but also, the materials may not be secured properly.

Holes in the knurled portion of the screws, are for a tommy bar, if more pressure is required, during the clamping process. |

| |

|

|

| |

| PHOTO-REALISTIC IMAGE OF TOOLMAKERS CLAMP |

| |

|

| |

| The two diagrams below, show the toolmakers’ clamp being used to secure / hold material, during practical work. |

| |

|

| |

|

|

| |

| Toolmakers’ clamps can used, to secure material to an angle plate, prior to being drilled, using a bench drill. The angle plate has been secured to the table of the drilling machine, by bolts. Two toolmakers’ clamps, are use to secure the material, to the vertical side of the angle plate. Note: this system of securing work for drilling, is fine for ‘lighter’ materials. |

| |

|

| |

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|