V.Ryan © 2021

Always take care when handling tools and equipment. Most tools have sharp edges, capable of cutting and slicing into hands and fingers.

Do not ‘fool around’ with tools and equipment. Always handle them according to instructions given by your teacher.

Store tools away, when they are not being used.

The image opposite shows milling tools being handled foolishly, which has severe consequences.

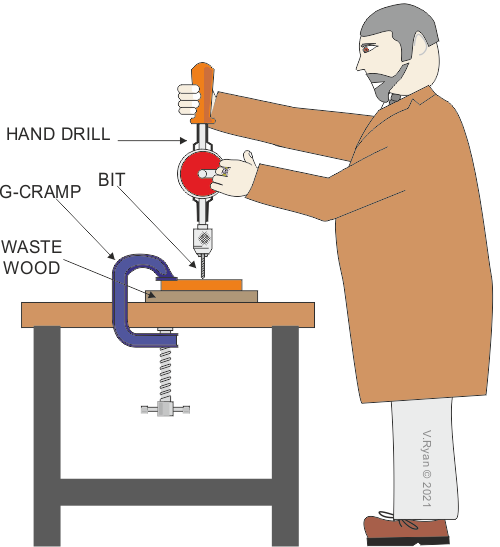

This is a good example of an everyday tool such as a hand drill not being handle with carelessly and dangerously.

1. The hand drill is not being held vertically and the work is not clamped to the bench.

2. The work is has not being placed in ‘waste / scrap wood’.

When using the hand drill, it is likely to slip, in the direction of the user. The drill bit is sharp and capable of cutting through wood and even metal. It will cut into flesh with ease.

1. It is held vertically.

The work being drilled rests on waste wood, so that the bench is not damaged by the drill bit. as it goes through the material being drilled.

2. The work and waste wood is secured to the bench with a G-cramp and will not slip.