| CLICK HERE FOR INDEX PAGE | ||

| REVISION CARDS - NON-FERROUS METALS | ||

| V. Ryan © 2012 | ||

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | ||

|

|

||

|

||

|

FERROUS AND NON-FERROUS METALS Ferrous metals contain IRON These are metals that contain iron. Consequently they tend to rust / suffer from corrosion. They need protecting with paint, oil or a surface finish. They react to a magnet. Non-ferrous metals do not contain IRON Non-ferrous metals do not contain iron. Consequently, they do not to rust or suffer unduly from contact with moisture. They do not react to a magnet. |

NON-FERROUS METALS ALUMINIUM Light grey in colour. Smelted from bauxite ore. Aluminium 95%, Copper 4%, Manganese 1% Ductile, soft, malleable, machines well on lathes and milling machines. Very light and resists corrosion. Can be cast into products from ingots. Used widely in aircraft, drinks cans, window frames, ladders, and kitchen ware.  |

|

|

NON-FERROUS METALS COPPER Reddish brown in colour, darkens slowly when in contact with air. This metal is not an alloy. Ductile, can be beaten into shape as it is relatively soft. Conducts electricity and heat. Electrical wiring, tubing, kettles, bowls, pipes and plumbing. Used also in the production of printed circuit boards.  |

NON-FERROUS METALS BRASS A copper alloy. Deep yellow to golden colour. An alloy, mixture of copper and zinc 65% - 35%. Casts and machines well. Surface tarnishes slowly on contact with air. Conducts electricity. Resists corrosion. Parts for electrical fittings, engineering, ornaments, musical instruments.  |

|

|

NON-FERROUS METALS BRONZE A copper / tin alloy. Tin content up to 10%. Engineers well on lathes and works quite well with handtools. Once used for ship fittings, due to its resistance to corrosion. Now replaced by stainless steel. Used for ornaments, cast bronze sculptures and ships propellers. Used also for bearings in engineering.  |

NON-FERROUS METALS PEWTER Pewter is a soft, malleable alloy, 85% to 99% tin. Other metals are copper, lead, antimony and bismuth. Has a low melting point compared to many metals (170–230 °C) making it highly suitable for casting. Usually purchased in ingots and cast to shape in a workshop. Used for making tankards and other decorative pieces.  |

|

| QUESTIONS | ||

| 1. What is the difference between ferrous and non-ferrous metals? | ||

| 2. Is copper an alloy? Tick the correct answer. YES NO | ||

| 3. What metals combine to form the alloy brass? | ||

| 4. Describe some practical uses of brass? | ||

| 5. Bronze was once used for ships fittings. Why? | ||

| 6. Pewter is suitable for casting. Why? | ||

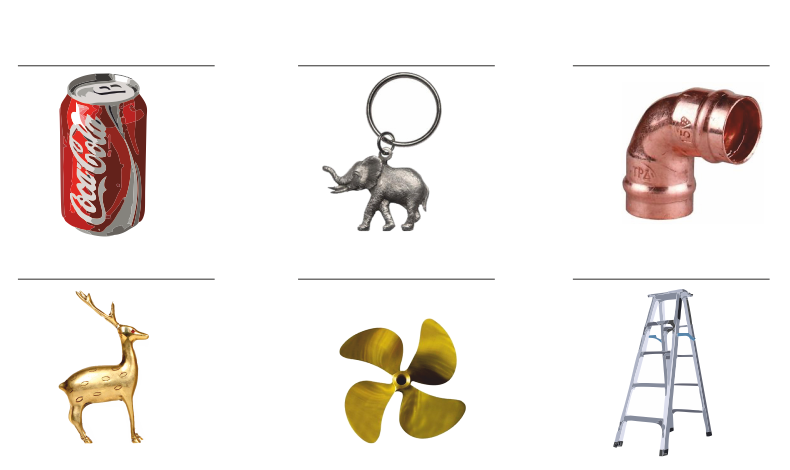

| 7. The products below have been manufactured from non-ferrous metals. Write the name of the most suitable non-ferrous metal, above each product. | ||

|

||

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | ||