| CLICK HERE FOR INDEX PAGE |

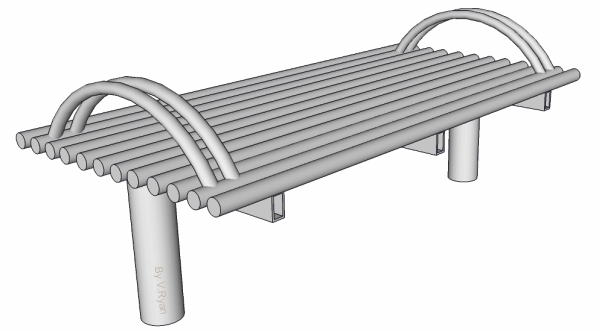

| MILD STEEL BENCH CONSTRUCTION |

| V. Ryan © 2011 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| Below are the stages involved in the manufacture of the mild steel bench. |

|

| CUTTING STEEL TUBE TO LENGTH |

|

The legs are manufactured from mild steel round section

tube. The tube is first cut to length using a machine hacksaw or if speed

is important, a powerful tube cutter is used. This is more like a

guillotine which slices through steel or aluminum with ease. |

|

| The mild steel tube can be cut to length using a power/machine hacksaw. This thickness of material cannot realistically be cut by hand. |

|

| SMOOTHING BURRS AND ROUGH EDGES |

| A hand file is used to smooth all the sharp edges. This can be followed by emery cloth (if required). This will smooth the steel further. |

|

| USING A JIG TO FORM THE CURVES / ARCHES |

| The steel tube arches / curves for the bench, are formed by heating each tube to ‘red’ heat and ‘bending’ on a sturdy steel jig. |

|

| STEEL WELDING WITH AN OXY-ACETELENE TORCH |

| The steel tube frame is gas welded together (oxyacetylene gas mixture). The steel could also be brazed or mig-welded or even welded by electric arc equipment. |

|

| GALVANISED OR SPRAY PAINT |

| The steel frame is galvanise (zinc

coated). This helps prevent rust / corrosion. Steel is galvanised through

a chemical process. The steel is given a zinc coating and as zinc does not

rust - rust cannot take hold. The zinc coating is added to the steel by submerging it in molten zinc. The zinc becomes part of the outer layer of the steel.. |

|

| For an even better weather resistant

finish, the mild steel is galvanised and then spray painted. This is the

most expensive option. Alternatively, spray paint instead of galvanising. Although this will prevent corrosion, if the paint finish is scratched, corrosion will begin. If this option is selected, the surface of the steel is coated with a rust resistant primer first, followed by a top coat. |

|

| THE COMPLETED STEEL TUBE BENCH |

| The bench is then transported to a permanent site. It is bolted to concrete foundations. During the assembly process galvanised nuts and bolts are used. Again, this helps prevent rust. |

|

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE |