| CLICK HERE FOR INDEX PAGE |

| PREPARATION OF STOCK - PLANING OF BOARDS |

| V. Ryan © 2011 |

|

When ordering natural wood, information such as how it

is to be prepared, must be included on the order form. This includes the

section / size and whether it will be supplied rough sawn or planed. |

|

| PLANED ALL ROUND (PAR) All the sides and edges are planed square, straight and level, leaving a smooth finish and ready to use. |

| PLANED BOTH SIDES (PBS) Both sides are planed but not the edges. The edges are left rough sawn. |

| PLANED SQUARE EDGE (PSE) Only one edge is planed accurately, making marking out and cutting to size more precise. |

| ROUGH SAWN The wood has rough surfaces produced by the circular / band saw, although they are relatively straight and level. |

| PLEASE NOTE: Even though wood may have been machine planed, a real craftsman / craftswoman, will finish the edges and sides by hand, using a smoothing and jack plane. |

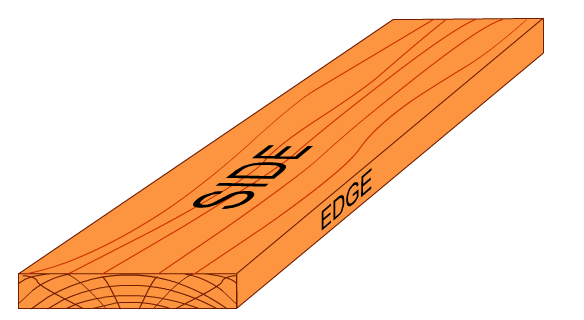

| HOW TO CHECK THAT EDGES AND SIDES ARE ACCURATELY PREPARED |

| A try square is used to check that both the face edge and face side are perfectly flat and level across the width of the wood. It may be necessary to use a plane to remove more wood, ensuring accurately finished surfaces. |

|

| A long steel rule / straight edge is also used to check that the face edge and side are perfectly straight along their entire length. If light shines through at any point of contact, then the surface is not straight/flat. |

|

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE |