| CLICK HERE FOR INDEX PAGE | |

| VENEER | |

| V. Ryan © 2011 | |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

|

|

|

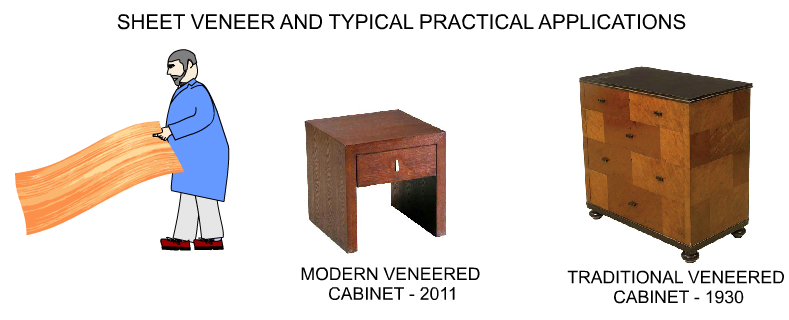

| Veneer is a thin sheet/layer of natural wood, usually a similar thickness to cardboard. It is produced from a tree trunk in a number of ways. The most popular method is to ‘peel’ a layer of thin wood (veneer) with a cutter, whilst the tree trunk revolves on a large lathe. |  |

| ROTARY CUTTING MECHANICAL SINGLE-CHUNK PEELING LATHE,VENEER ROTARY LATHE |

|

|

|

| Veneer is available in two

forms, sheet and rolls. The larger sheet veneer is usually glued onto the

surface of a cheaper manmade board, giving the illusion of expensive

natural wood. In its simplest form, a roll of ‘iron on’ veneer can be used to glue along the edge of a board, providing a quality finish and hiding the cheaper board beneath. |

|

|

|

| HOW TO VENEER THE EDGE OF A BOARD | |

| ‘Iron on’ veneer is purchased

in the form of rolls. It is supplied in a range of widths, lengths and

woods. One side is natural wood and the other is a layer of glue/adhesive. To use: A strip of veneer is cut slightly longer than the edge of the board. It is positioned on the edge of the manmade board, natural wood side facing upwards. A ‘hot’ iron is placed on top of the veneer. This warms and melts the glue. As the iron is pushed along the strip, the veneer is glued to the edge of the manmade board. A craft knife is used to trim the veneer to the exact size. |

|

|

|

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | |