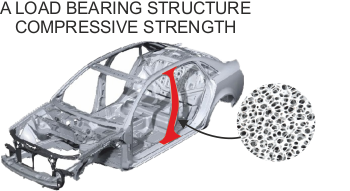

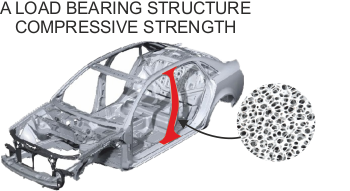

Less metal is required to make the frame and yet it improves its strength and resistance to compression.

If the train crashes, the front crumples, with the metal foam structure absorbing the impact, helping to protect the driver and passengers.

| CLICK HERE FOR INDEX PAGE | ||

| THE PRACTICAL APPLICATION OF METAL FOAMS | ||

| V.Ryan © 2018 | ||

| Video - Metal Foams | ||

|

||

| The colour red, identifies the metal foam area | ||

|

Metal foam is found in the frame / substructure of some cars. This saves weight, but also adds strength to critical areas and provides improved safety, in the event of a crash / accident. Less metal is required to make the frame and yet it improves its strength and resistance to compression. |

|

|

Crumple zones are not a new idea, but if these zones incorporate metal foam, their effectiveness is increased. The saving in weight, is also a positive characteristic. If the train crashes, the front crumples, with the metal foam structure absorbing the impact, helping to protect the driver and passengers. |

|

|

The low thermal conductivity of metal foams, means that they are ideal as the ‘core’ of handles, for kitchen pots and pans. Foams conduct heat very slowly, and dissipate the heat through the air filled pores of the internal matrix. | |

|

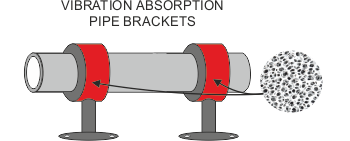

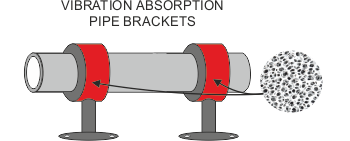

Foam metals absorb vibration really well, making this type of material ideal for the manufacture of special brackets, holding pipes that tend to vibrate. This protects the pipe from fracturing, whilst vibrating. The vibration is adsorbed and dissipated by the foam metal bracket. These brackets are used where vibration could cause a failure, which could lead to a serious accident, e.g. fuel distillation. | |

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | ||

|

||