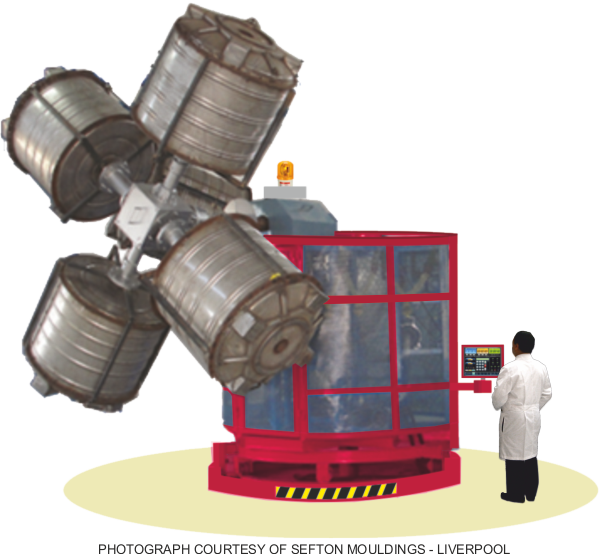

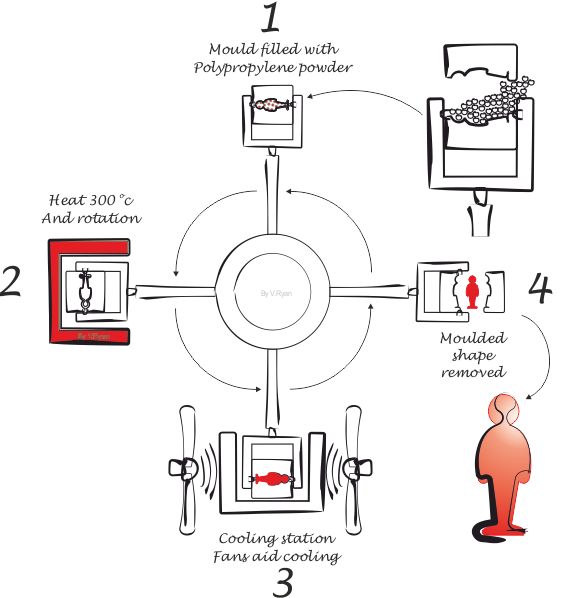

Rotational moulding is a four stage process.

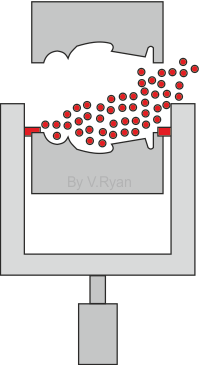

1. The mould opens and is filled with powdered polyethylene or polypropylene and closed. The moulds are usually manufactured from aluminium, on CNC machines . Accuracy is vital, as any fault will be repeated in the finished product, every time one is manufactured.

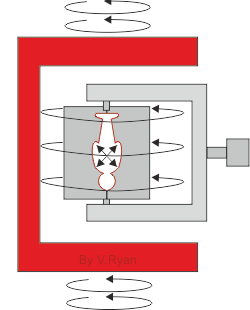

2. The mould moves to the next stage, where it is heated to 300oC. At the same time the mould rotates so that the powder is forced against the wall of the mould.

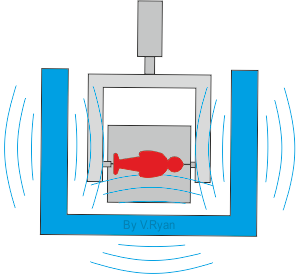

3. The mould moves onto the cooling stage. Cool air is blown around the mould, aided by large fans. The mould cools slowly and solidifies.

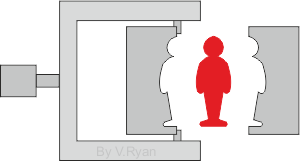

4. The finished product is then removed.

ADVANTAGES:

The investment in equipment and tooling is less than vacuum forming and blow moulding.

It is a profitable process even when manufacturing 100 units.

1

MOULD FILLED WITH

POLYPROPYLENE POWDER

MOULD FILLED WITH THE CORRECT WEIGHT OF POLYETHYLENE / POLYPROPYLENE

2

HEAT 300 DEGREES CENTIGRADE

AND ROTATION

THE MOULD IS HEATED TO 300oC AND ROTATED, FORCING THE POWDER AGAINST THE SIDES OF THE MOULD

3

COOLING STATION

FAN AID COOLING

THE MOULD IS COOLED AND THE CONTENTS OF THE MOULD COOLS DOWN SLOWLY

4

MOULDED PRODUCT REMOVED

THE FINAL PRODUCT IS REMOVED FROM THE MOULD AND THE ROTATIONAL MOULDING PROCESS STARTS AGAIN