V.Ryan © 2021

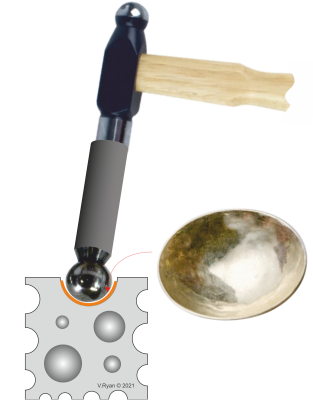

The punch should be moved around the surface of the metal in a uniform way, ensuring the selected area is hammered / punched, with the same force / effort.

| CLICK HERE FOR INDEX PAGE | ||

| DOMING BLOCK AND PUNCHES | ||

V.Ryan © 2021 |

||

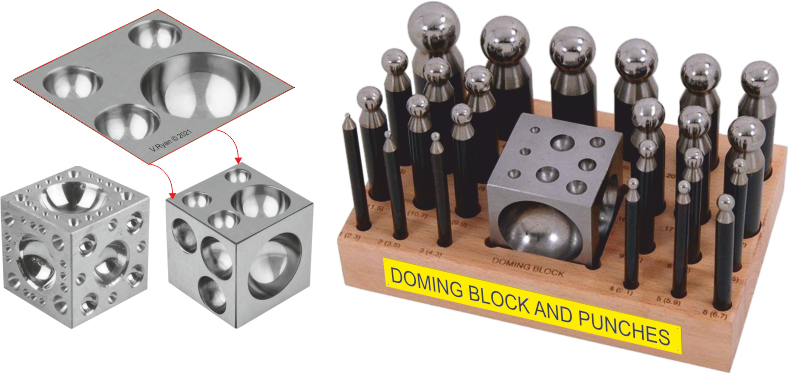

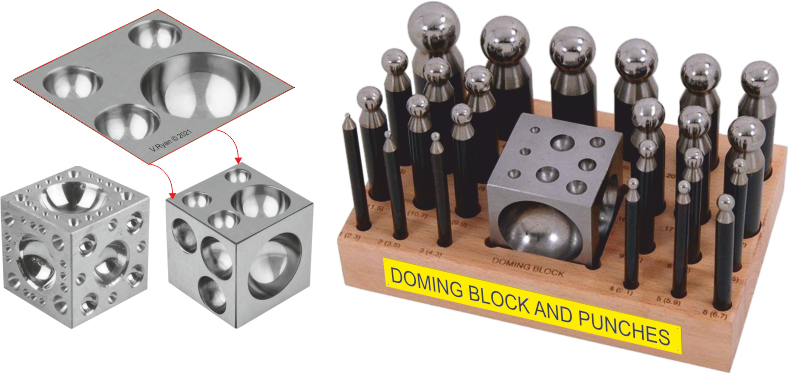

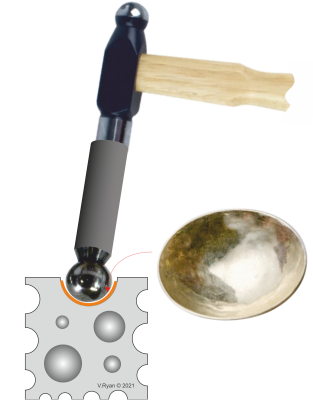

| A doming block, is a polished cube and on each side are graded hollows (semi-spherical holes). They are used for creating accurate curves / domes in sheet metal. The punches have polished heads. It is very important to ensure that the blocks and punches, remain in perfect condition and that they do not become damaged in any way. Scratches on either the punch or block, will be transferred to the metal being worked. | ||

|

||

|

When doming annealed metal, the first stage is to select the largest punch and to work in the largest hole in the block. The punch and hole can be reduced one at a time, until the desired size is reached. The punch should be moved around the surface of the metal in a uniform way, ensuring the selected area is hammered / punched, with the same force / effort. |

|

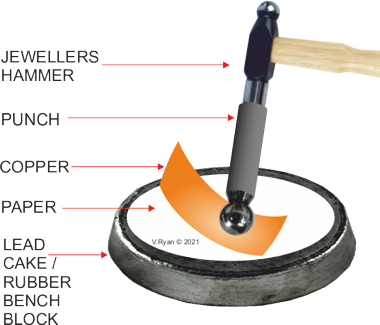

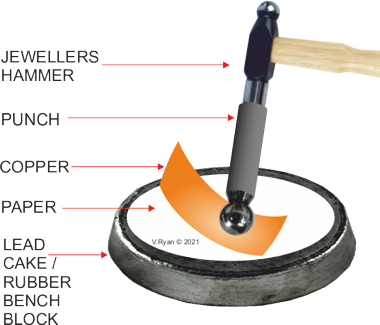

| A lead cake / lead block is very useful (or the modern lead free equivalent, called a rubber bench block), especially when working with punches to produce curves in metal. The lead / rubber absorbs the force of the punch, without damaging the surface of the metal being formed. However, it is important to cover the lead surface with a piece of paper, to prevent the lead contaminating the metal being worked. A rubber block does not present this problem. |  |

|

| CLICK HERE FOR JEWELLERY INDEX PAGE | ||

|

||