V.Ryan © 2021

(WEAR A DUST MASK WHEN SIFTING ENAMEL)

| CLICK HERE FOR INDEX PAGE | ||

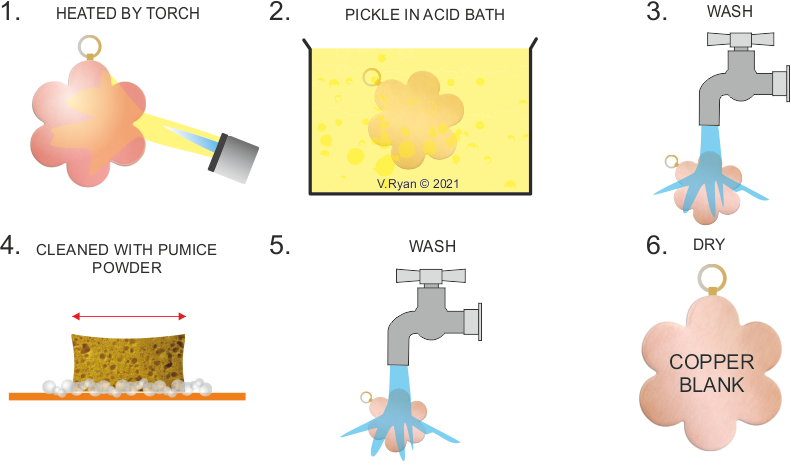

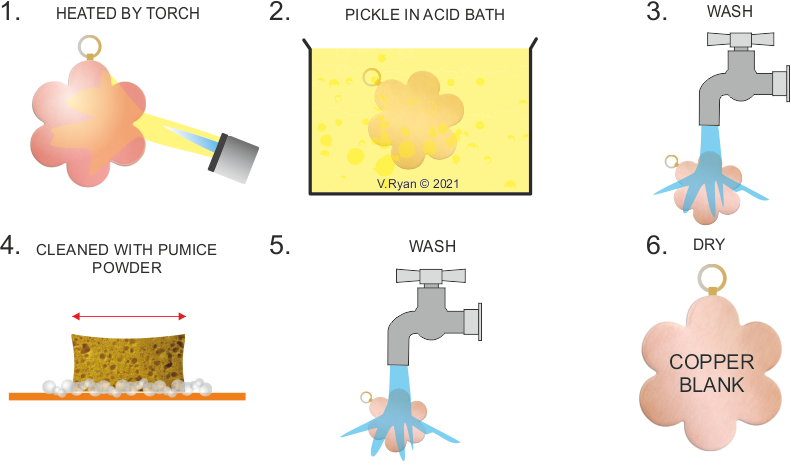

| PREPARING THE METAL FOR ENAMELLING | ||

V.Ryan © 2021 |

||

| Nonferrous metals are sometimes given an enamel finish. The surface of the metal must be prepared carefully, because any ‘dirt’ or ‘grease’, will prevent or damage the enamel process. A metal such as copper, should be heated with a gas torch, to burn away any grease, followed by pickling in an acid bath and washing in clean water. The copper is then cleaned with a water / pumice powder paste, followed by a final wash. If soldering has already taken place, for example a ring for a chain has been added to a back piece, enamel solder must be used. Any other solder will melt during the enamelling process. | ||

|

||

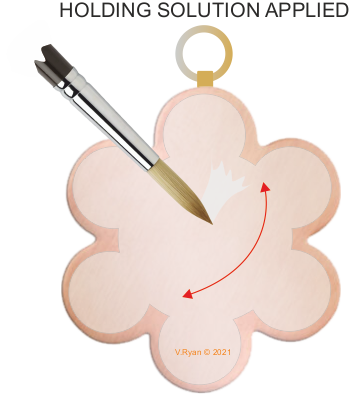

| APPLYING THE ENAMEL | ||

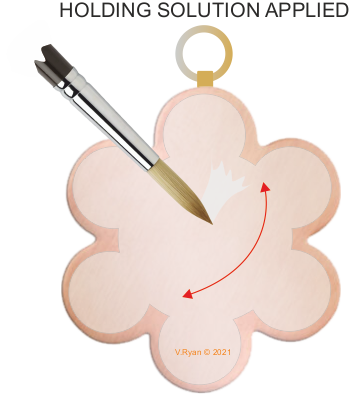

| A ‘holding’ solution (enamel adhesive) is applied to the copper surface to be enamelled. This helps to keep the powdered enamel in place during heating. Traditionally, a solution of gum tragacanth / water, is brushed on to the surface. There are also cheaper, commercial holding solutions / adhesives, that are as easy to apply, such as jewellers cellular adhesive or klyr-fire gum solution. |  |

|

| Before applying the enamel, it should be placed in a bowl. Add water carefully to the enamel powder and swill the mixture around the bowl. Allow the enamel grains to settle and pour away the water. Allow the enamel powder to dry. | ||

|

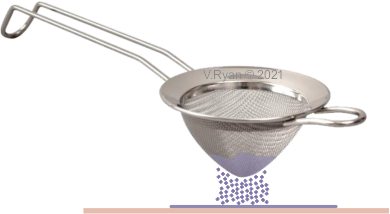

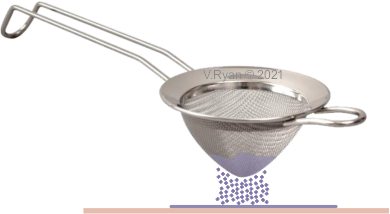

To load the surface with enamel powder, tap the sieve and it will fall through the mesh. Distribute the powder evenly, across the section to be enamelled. Remove excess water / solution with a tissue. (WEAR A DUST MASK WHEN SIFTING ENAMEL) |

|

| CLICK HERE FOR JEWELLERY INDEX PAGE | ||

|

||