V.Ryan © 2021

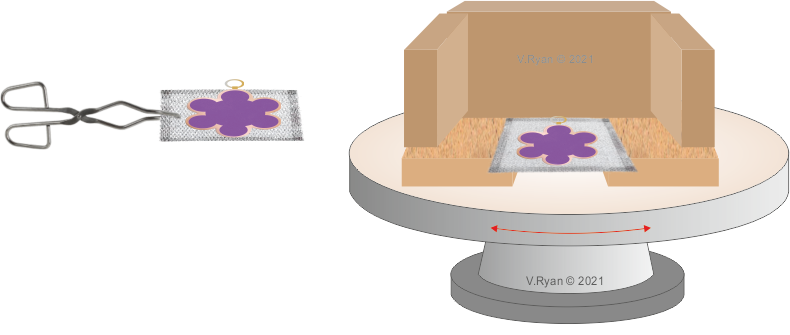

The wire gauze with its metal and enamel, is transferred to and from the brazing hearth, using tongs. It is placed on and surrounded by fire bricks, as shown below. The gap between the fire bricks underneath the metal, allows the flame to heat from below.

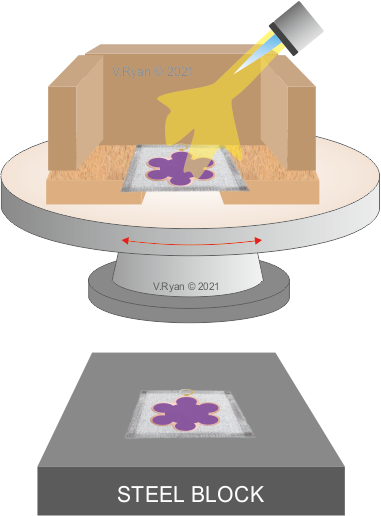

The metal and enamel is gently heated using a broad flame, held at a distance and moved around the metal, from above and below. This allows any remaining moisture to evaporate, without disturbing the enamel powder.

The flame is then slightly focussed and heating continues from below the metal. It is important at this stage, to watch for a change in the enamel. The enamel will darken and then melt, producing a rippled effect (this looks similar to the texture of an ‘orange peel’). The flame should be removed and heating stopped. Allow the metal to cool for a couple of minutes and then move it to a surface, such as an anvil or a steel block.

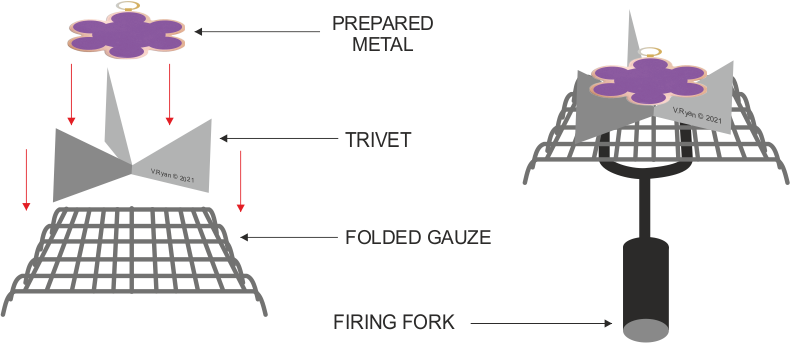

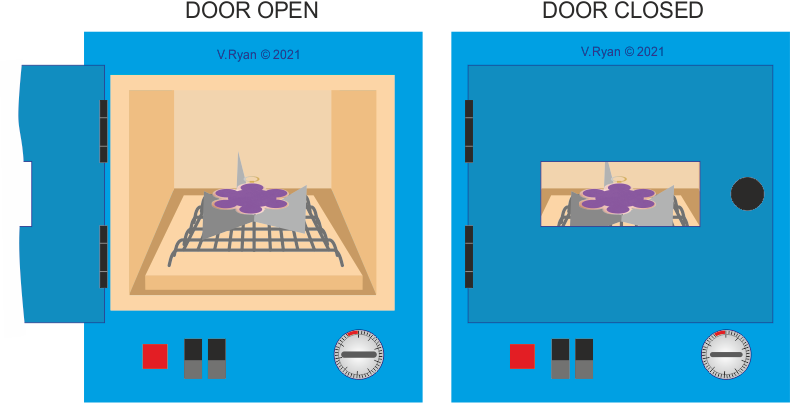

A second coating of enamel can be applied (if required). The heating and cooling process is repeated. This second ‘firing’, produces a level finish to the enamel (called ‘full fuse’). The second firing / heating, is best suited to a kiln, where the heat around the metal is uniformly distributed.

Kilns distribute the heat / temperature evenly around the interior, unlike a gas torch. However, for some enamelling, a gas torch may be the best choice, as it gives the user control to the focus / remove the heat.

GUIDANCE - FIRING TEMPERATURES

Always read the instructions and guidance provided by your enamel supplier.

Opaque: 810C - 830C

Transparent: 820C - 840C

Always use heat resistant gloves.

Wear safety goggles and a leather apron.

Always use extraction in your work area.

Always follow health and safety guidance and laws, associated with the heat treatment of metals.