| CLICK HERE FOR INDEX PAGE |

| |

| THE BOW DRILL AND PENDANT DRILL |

V.Ryan © 2021 |

| |

| |

|

|

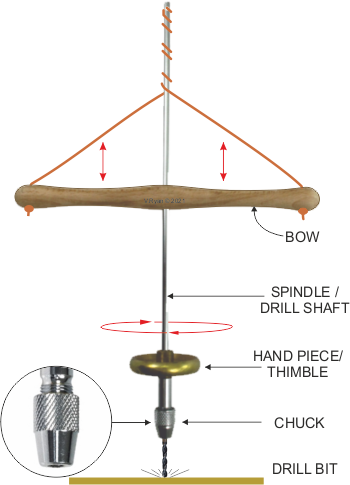

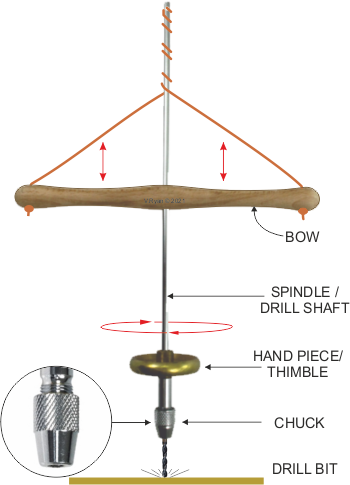

A typical bow drill is made from steel, brass and wood and is the height of a standard 300mm ruler. Rotation of the drill chuck, is achieved by twisting the wooden handle around the steel centre pole, which also twists the cord, providing tension.

When the wooden handle is moved up and down, the chuck rotates at a remarkably fast speed (linear motion converted to rotary motion). One hand operates the motion of the bow, up and down and the other hand holds the work being drilled. The technique is mastered relatively quickly.

Primitive forms of the bow drill, have been in use since the Stone Age.

|

| |

|

|

| |

| THE PENDANT DRILL |

| |

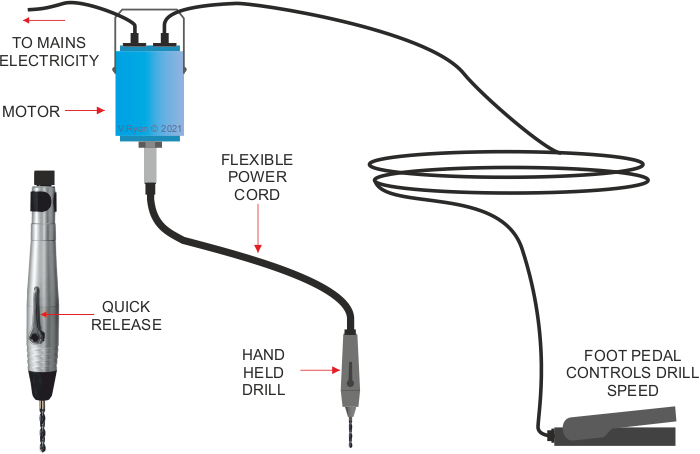

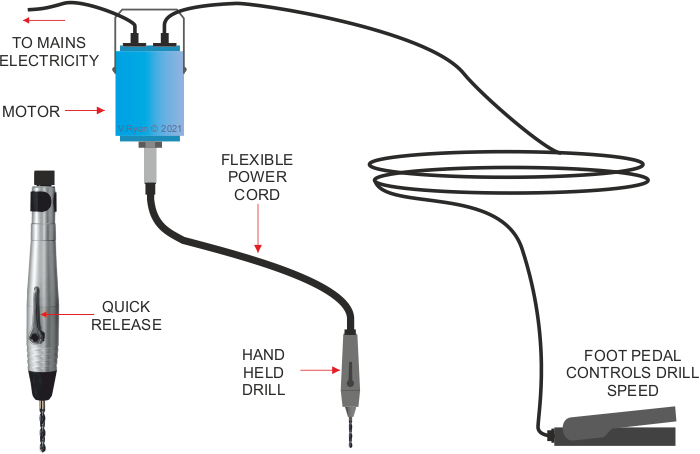

| Pendant drills are very useful, mainly because they have a flexible lead, which means that they can be control by hand easily. The motor is suspended from above, often from a stand. The speed of rotation / the drill bit, is controlled by a foot pedal. |

| |

|

| |

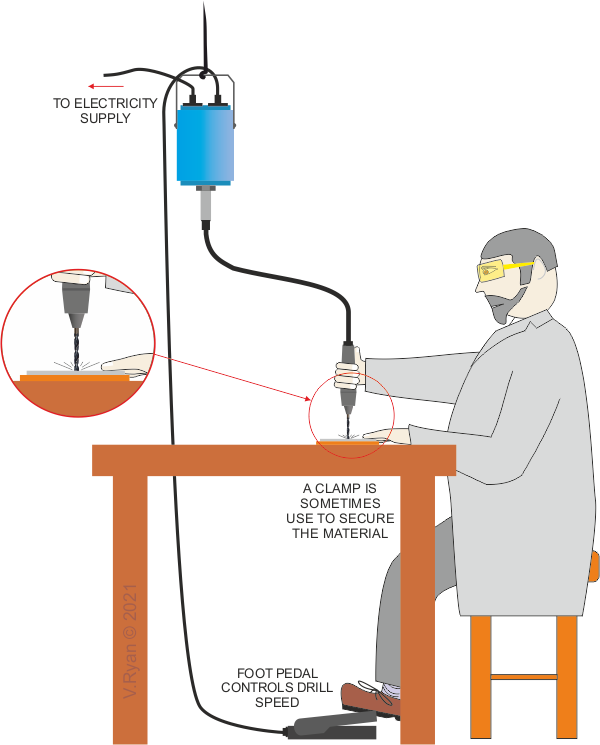

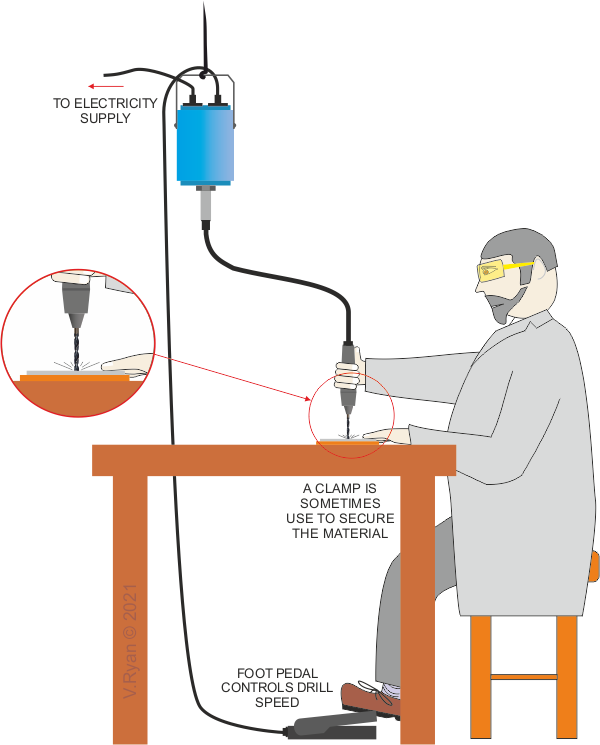

This pendant drill is being operated by a jeweller. He holds the material being drilled in one hand, at the same time operating the drill and controlling its position. He uses the foot pedal to control the speed (rpm).

Pendant drills can be used for a range of techniques, including polishing, grinding, sanding, in addition to drilling. Some of the available attachments are shown below. |

|

| |

|

|

| |

| PENDANT DRILL ATTACHMENTS |

| |

|

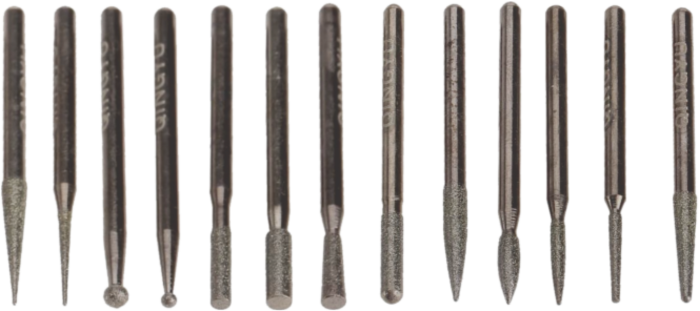

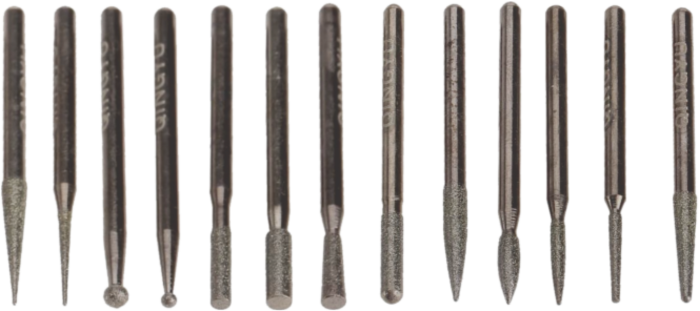

| Below is a selection of diamond coated grinding bits, ideal for use with a pendant drill. They are suitable for grinding, cutting, engraving and polishing a range of resistant materials including, tungsten steel, jade, ceramics, glass, carbide and stone. |

| |

| 3MM SHANK DIAMOND COATED GRINDING BITS |

| |

|

| |

|

|

| |

| CLICK HERE FOR JEWELLERY INDEX PAGE |

| |

|

| |

|