| CLICK HERE FOR INDEX PAGE |

| |

| INLAYING METAL STRIPS AND WIRE |

V.Ryan © 2021 |

| |

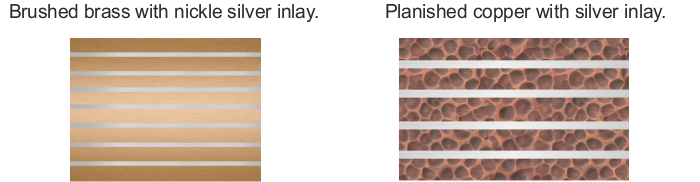

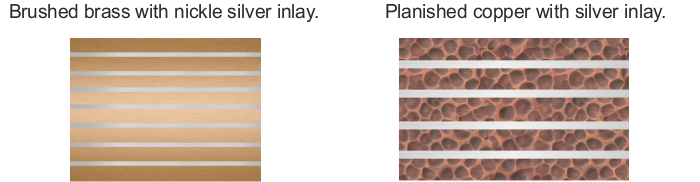

| Inlaying metals is a really interesting way of adding detail to jewellery. This techniques increases contrast between the various inlays, in terms of colour and surface reflection. The basic tools required for this process include; a wedge shaped punch (which can be homemade), a hammer and graver. |

| |

|

| |

|

|

| |

| INLAYING WIRE |

| |

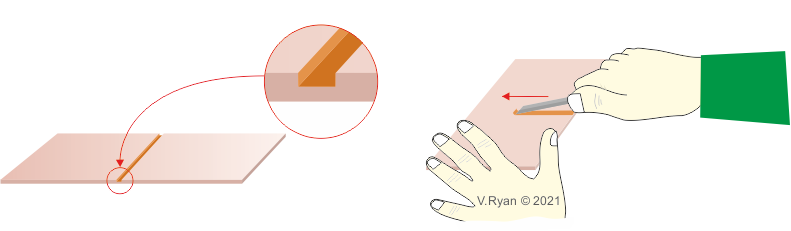

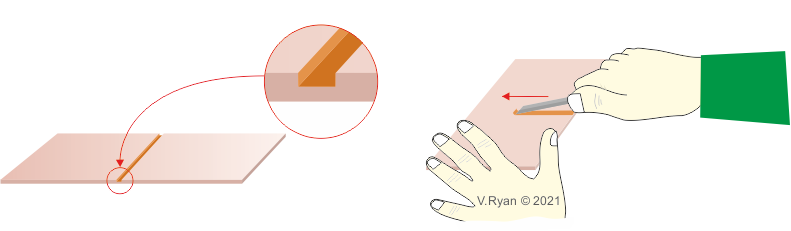

| Using a flat graver, cut a path across the metal. The metal must be annealed first. |

| |

|

| |

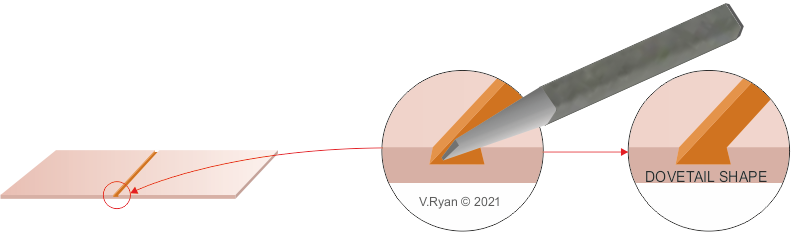

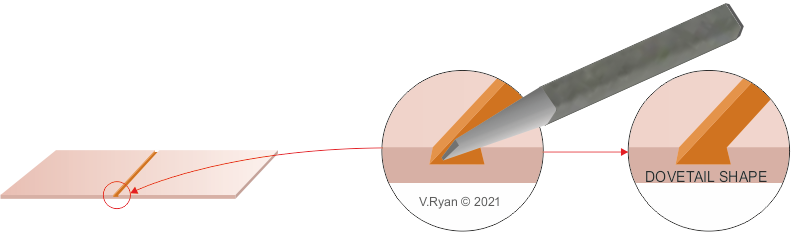

| Using the punch and carefully delivering ‘taps’ from the hammer, undercut the groove produced by the graver. It should resemble a ‘dovetail’ shape when finished. |

| |

|

| |

|

|

| |

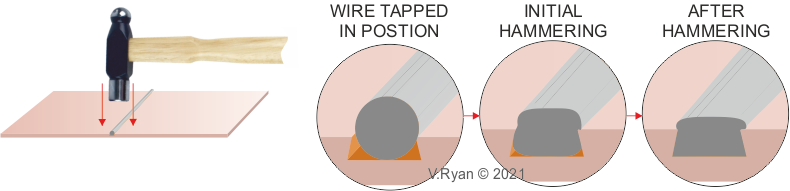

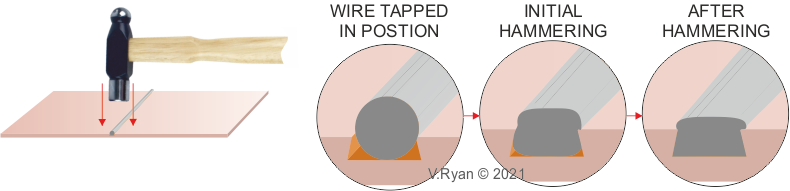

| Annealed wire is put in position. It should fit tightly into the groove, created by the graver and punch. Then, hammer downwards, spreading the wire into the dovetailed groove. Do this along the entire length of the wire. Careful hammering is required, because a poorly directed hammer blow, can damage the surface of the metal. |

| |

|

| |

| Use a suitable file, such as a flat needle file, to remove the excess metal, leaving a flat surface. The surface can be smoothed and polished in the usual way. |

| |

|

| |

|

|

| |

|

|

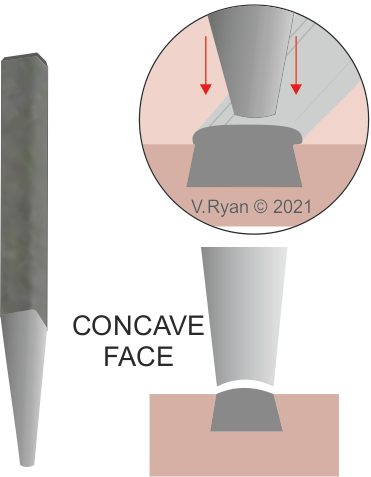

Alternatively, a punch can be used to ‘tap’ down the wire. One advantage, is that the punch can be positioned very accurately. However, if the punch is brought down on the surface of the metal, missing the wire, the resulting ‘dint’, may be impossible to remove / disguise.

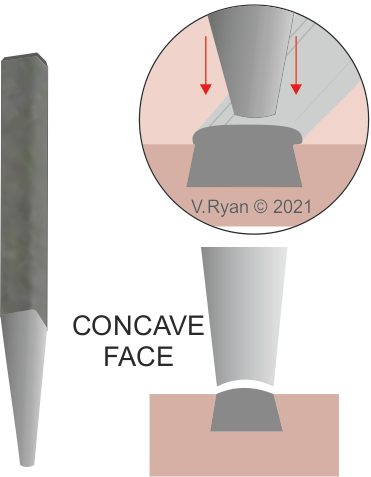

Inlays do not have to be level with the surface metal. With careful filing to remove most of the excess wire, followed by the use of a punch with a concave face, a rather interesting finish can be achieved. The wire ‘protrudes’ above the surface.

|

| |

|

| |

| |

| CLICK HERE FOR JEWELLERY INDEX PAGE |

| |

|

| |

|