V.Ryan © 2021

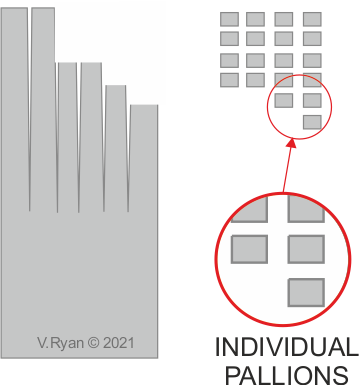

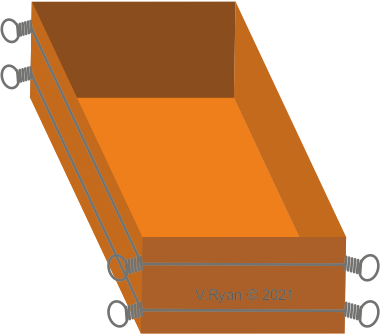

Solder can be bought as a flat strip and cut into ‘pallions’. The diagram opposite shows a solder strip, cut into thinner strips, with a pair of tinsnips and then cut into individual pallions.

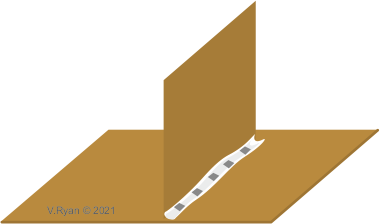

The pallions are then placed along the join line, and soldering takes place.

This is often the preferred soldering technique. It allows the jeweller to concentrate on the use of the gas torch. Also, when the soldering temperature is reached, the solder beings to flow along the joint, without the need to manipulate a solder stick.

Pallions are very useful in certain soldering situations.

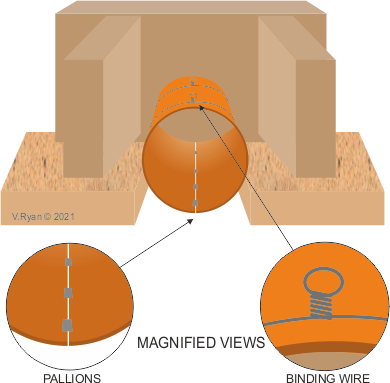

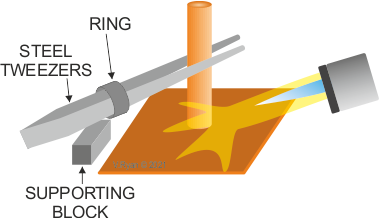

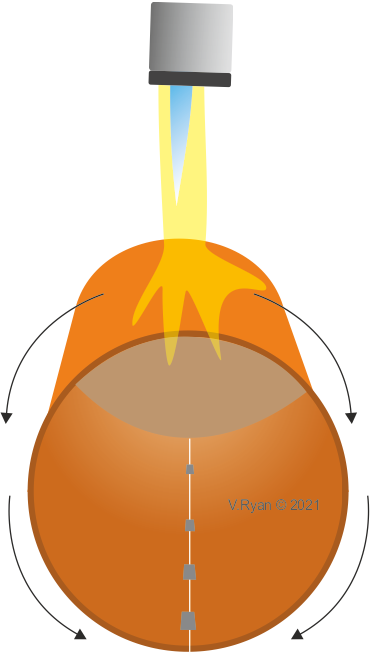

The cylinder shown opposite has been formed from one flat strip of copper, which has been rolled through a jewellery rolling mill. It is held in ‘shape’ by ‘binding wire’. This prevents the join from opening / widening, during the heating process. The binding wire has been ‘wrapped’ tightly around the cylinder and twisted at the top, to hold it in place. It will be removed after successfully soldering of the joint.

Pallions have been placed along the fluxed joint and will melt and run along the joint, when the correct temperature is reached.

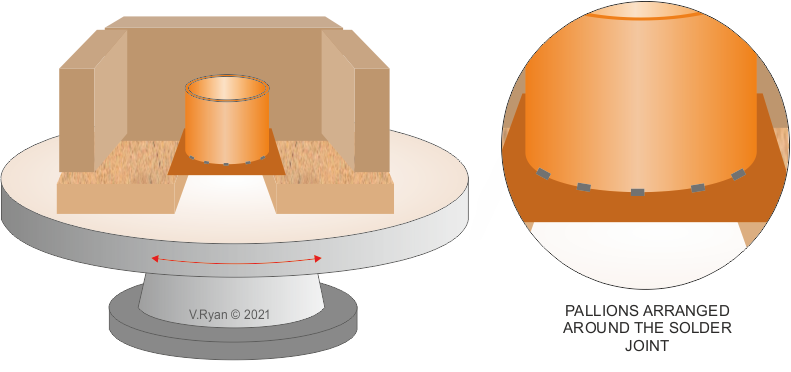

The fire bricks reflect the heat produced by the gas torch, back towards the material. The jeweller can rotate the ‘table’, in order to control the heating of the materials and the flow of the solder.

IMPORTANT: Binding wire must be removed before cleaning the soldered materials, in a pickling bath. Binding wire will contaminate the pickling solution.

Softly heat ‘opposite’ the join first and slowly work the heat of the torch to the seam / join. This will prevent the join from springing apart, as the metal expands. Concentrating the heat from the torch on the join / seam, will inevitably cause the metal on either side to expand and the ‘gap’ at the join / seam, will widen, preventing soldering.