| CLICK HERE FOR INDEX PAGE |

| |

| REPOUSSÉ |

V.Ryan © 2021 |

| |

| |

| Repousse is best described as, punching a decorative pattern / feature or character, in the back of a piece of annealed, malleable metal. This creates a design in ‘reverse’. Turning round the ‘repoussed’ metal, reveals the design. Below are some examples of repousse work dated from Egyptian to modern times. This type of work dates back thousands of years and is still a very popular way of adding detail and texture to sheet metals. |

| |

|

| |

|

|

| |

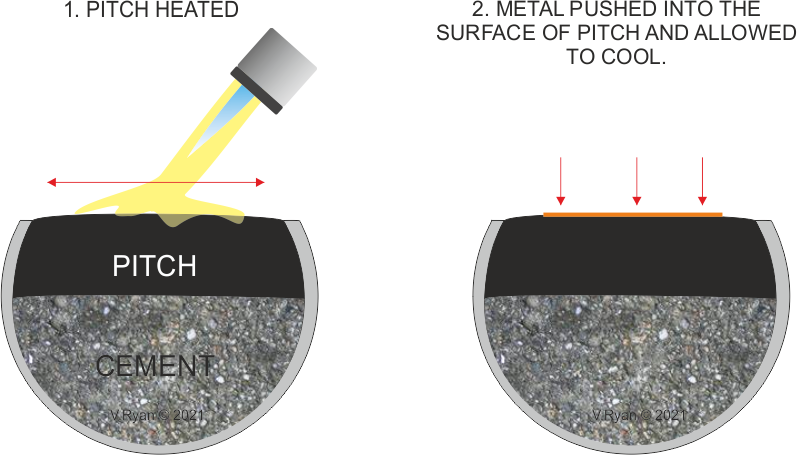

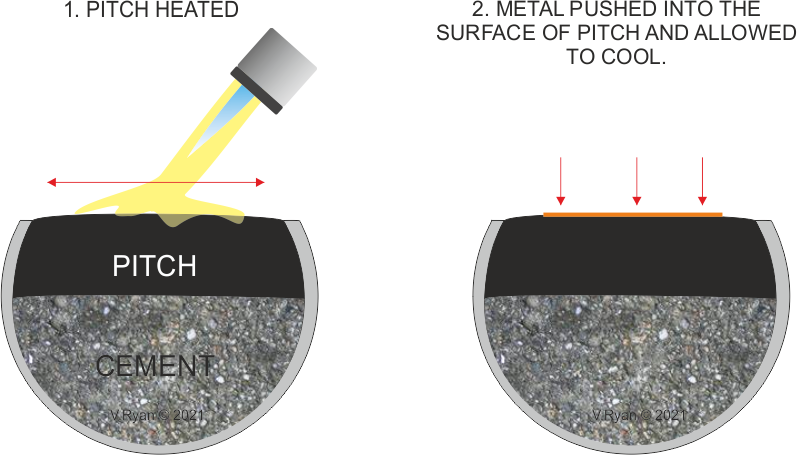

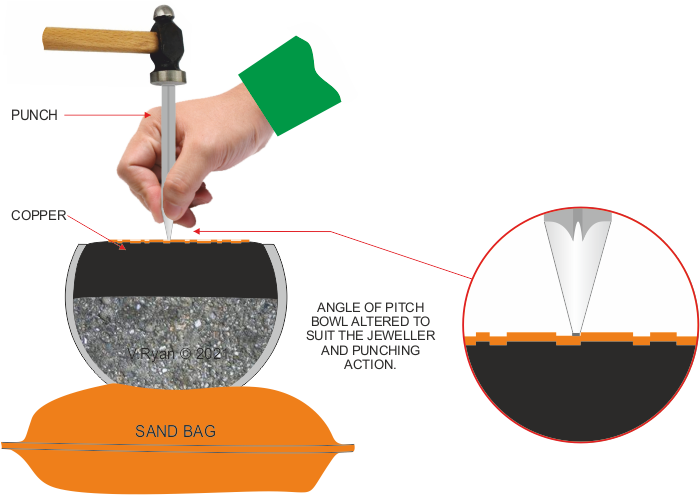

Traditionally, the metal rests on the surface of a bowl filled with pitch (pitch bowl). Pitch is made up of 2 parts pitch (a resin composed of bitchumen or asphalt), 1 part plaster of Paris, with a touch of tallow. This creates a substance that supports the sheet metal and has a small amount of give, which absorbs the punch, as it is hit by a hammer.

To save time, heat up a small amount of pitch, when it becomes ‘runny’, apply it to a wooden board and place the metal on top. When the pitch cools, it will hold the metal in place and retain a degree of pliability, absorbing the hammer blows, applied to a punch.

Engravers Red Pitch is available commercially and is ready for use (requires no mixing with other substances). It has low melting and softening points, which means it can be shaped by hand. It is a nontoxic alternative to black pitch. |

| |

| The pitch bowl has been 3/4 filled with cement and then topped with pitch (or engravers red pitch). The surface is heated with a blow torch, until it melts. The sheet metal is then set in to the surface and the pitch is allowed to cool. A design should have already been drawn / scribed onto the surface of the metal. |

| |

|

| |

|

|

| |

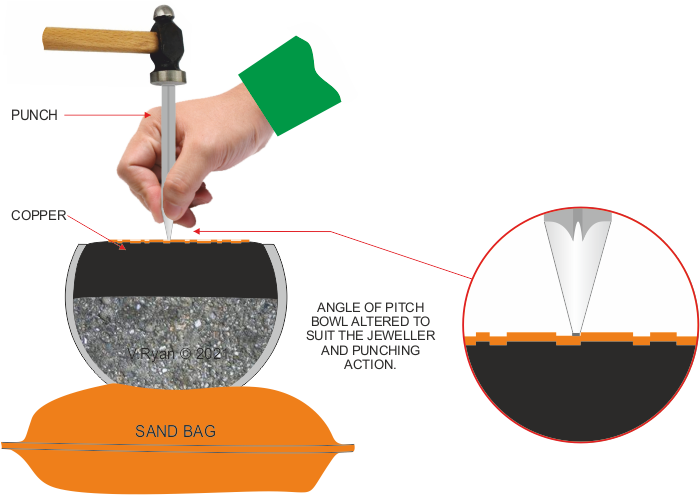

| The pitch bowl is placed on a sand bag. This supports the bowl during the hammering of the punch and also allows for 180 degrees of movement. |

| The magnified view, shows the punch making an indentation in the sheet metal. The jeweller carefully controls the repousse work, as he / she creates a detailed pattern / design. |

| |

|

| |

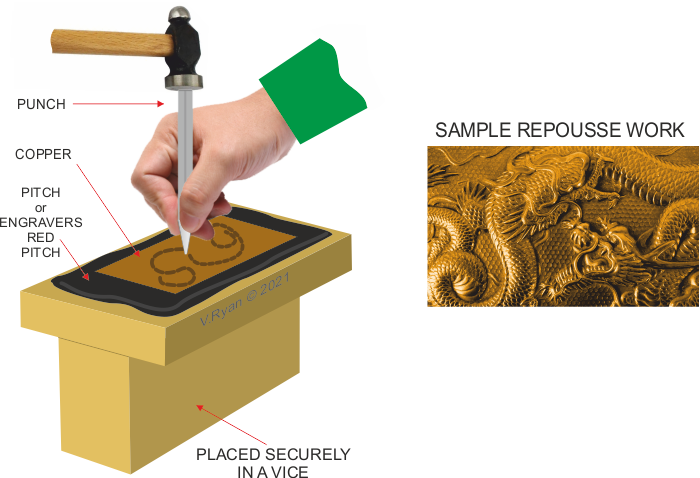

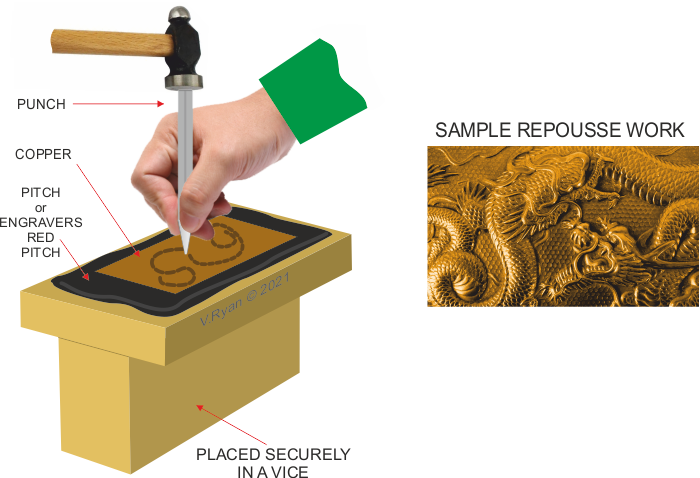

| Pitch has been applied to the surface of this wooden block (below) and a piece of sheet copper embedded in its surface. A punch is then used to start the repousse. When the repousse work is complete, after the skilled application of several types of punch, the pitch is heated up and the copper removed. When the metal sheet is turned over, it reveals the repousse design. |

| |

|

| |

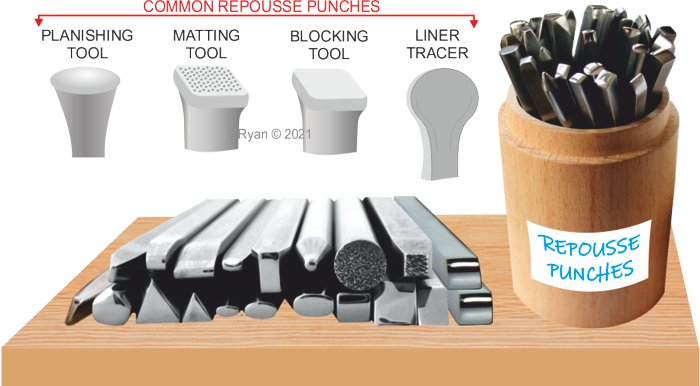

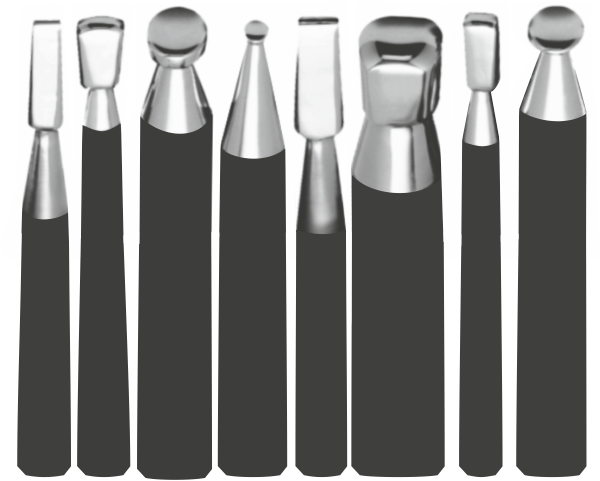

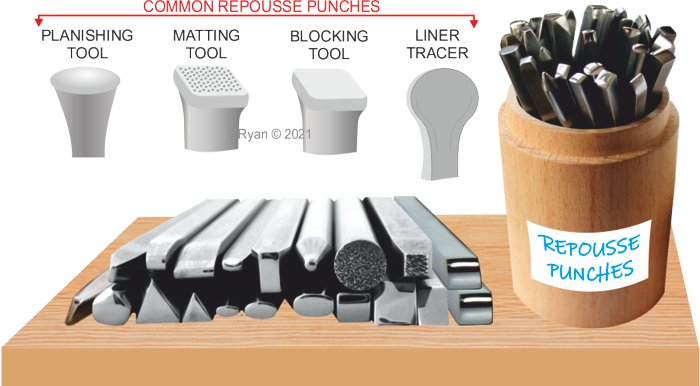

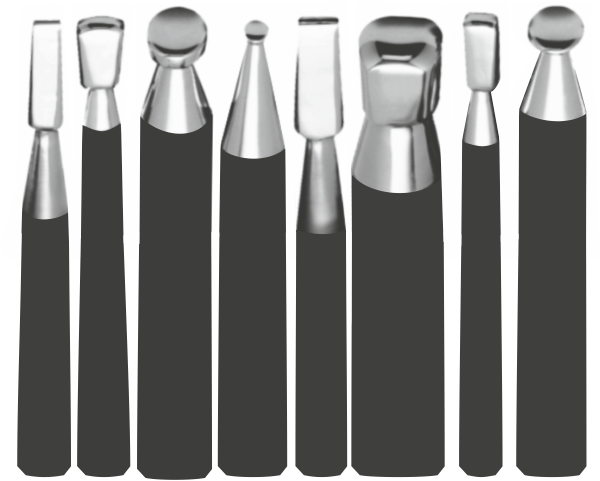

| Often, a series of punches are used, to produce one piece of detailed repousse work. Two sets of repousse tools are seen below and they include a small range of available punches. The four most popular / common types of punch are; line tracer, blocking, matting and planishing. A jeweller may decide to make punches, for a specialist piece of repousse work. |

| |

|

| |

|

|

| A line tracing punch / tool, is used to follow the outline of the pattern, that has already being ‘scribed’ into the surface of the metal. Blocking punches are for adding depth, over an area and are ‘wider’ in comparison to a line tracer. Matting tools have a patterned ‘face’. They are for adding texture to a surface. The patterns vary according to the texture being added to the repousse work. Planishing punches are used to smooth areas. |

| |

| Recommendation: Hold the punch, as if holding a pen / pencil. Start with a line chaser, following the ‘scribed’ lines on the metal’s surface, slowing increasing the depth of the ‘impression’. Other punches are selected and used, as and when required. It may be necessary to anneal the metal a number of times during the repousse process. To do this, simply heat up the ‘pitch’ with a gas torch and remove the metal with tweezers. Then anneal the metal and return it to the pitch. |

| |

|

|

| |

| HOMEMADE PUNCHES |

| |

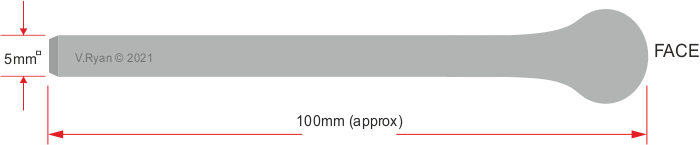

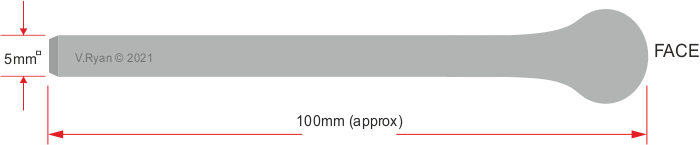

| Professional jewellers tend to make their own individualised punches. Start by filing a suitable section of tool steel (100mm x 5mm x 5mm). Form a chamfer at the end that will be hit with a hammer. The opposite end (the face), can be filed to produce the shape required OR as in this case, forged on an anvil and then filed. |

| |

|

| |

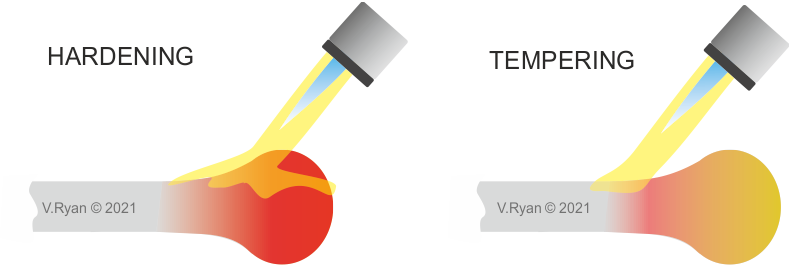

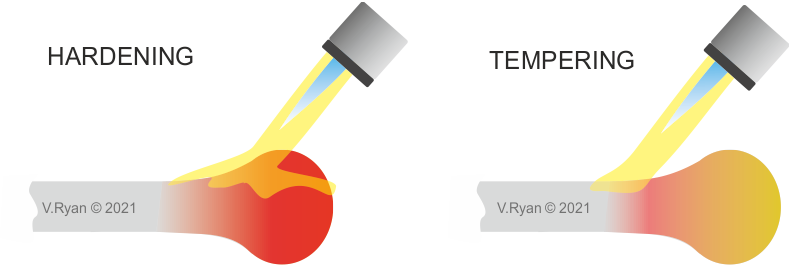

The ‘face’ is then hardened and tempered, to give it the strength and durability required for the repousse process. To do this:

To ‘harden’ the face, heat it up with a torch, until it changes in colour to ‘bright red’ and plunge it into clean, cold water.

To ‘temper’ the face, clean the metal so that is has almost a polished finish. Then start heating about 20mm from the face. Carefully watch for a colour change, as the metal heats up. When the face changes to a light straw colour, quench in clean cold water.

Finally clean and polish and the punch is ready for use. |

| |

|

| |

| This selection of jeweller’s punches show how highly polished they need to be, when carrying out professional level repousse work. |

| |

|

| |

| |

| |

| |

| |

| |

| CLICK HERE FOR JEWELLERY INDEX PAGE |

| |

|

| |

|