V.Ryan © 2021

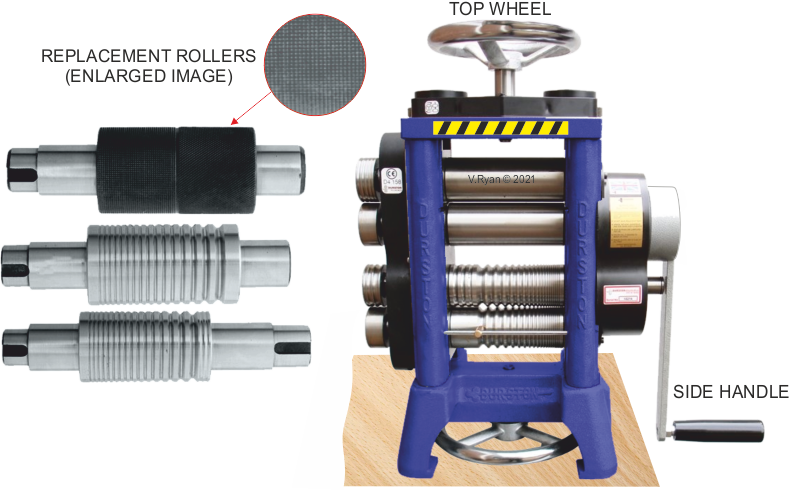

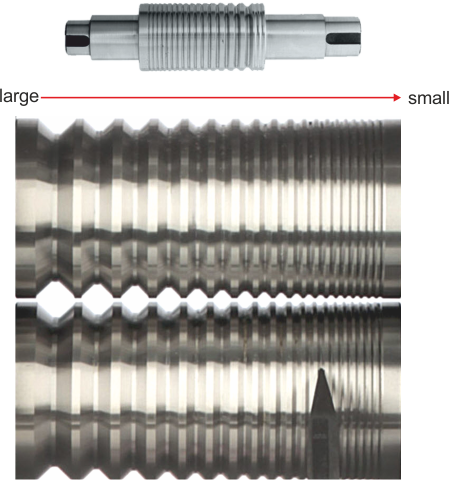

The smooth rollers are for flattening and curving sheet metal. The grooved rollers are for reducing the diameter of wire and for producing a taper. One of the replacement rollers shown below, is a textured roller, which imprints a pattern into the surface of sheet metal.

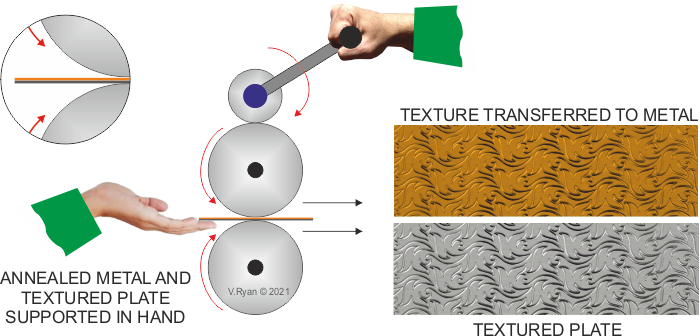

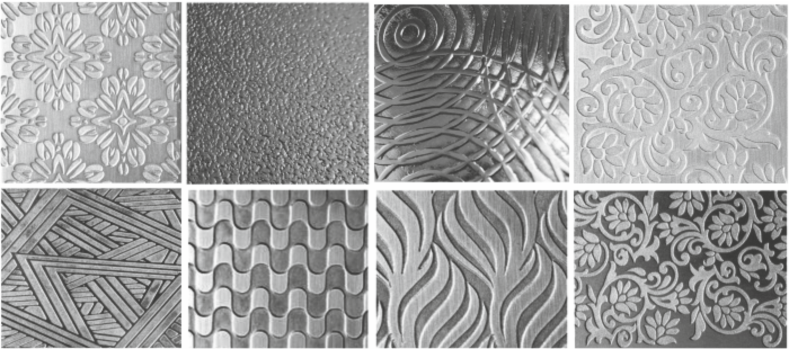

For wire, the grooved rollers are used and for sheet metal the polished rollers. Textured patterns can be purchased or made by hand. If they are fed through the rollers with sheet metal, the pattern / texture is imprinted into the surface (see below).

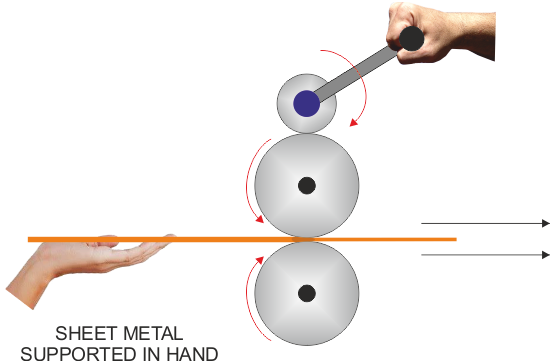

The roller width is adjusted by turning the top wheel. Start by altering the gap, so that the sheet metal just slides between the rollers when pushed by hand. Then, turn the top wheel slightly, to reduce the gap, so that it no longer slides through. Only a slight turn of the wheel is needed.

When the handle is turned, the sheet metal is pulled through the rollers and reduced in thickness. The procedure can be repeated until the desired thickness of metal is reached. The thickness is checked with a vernier caliper.

Alternatively, purchase a textured plate. Then, place the annealed metal sheet on top of the plate and feed them through the rolling mill. The pattern / texture will be transferred.