V.Ryan © 2021

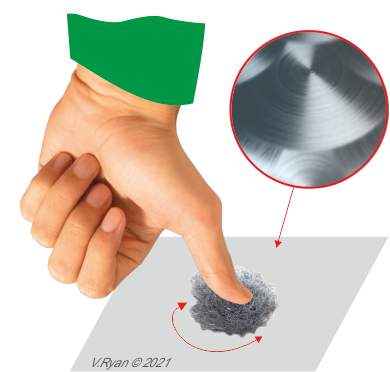

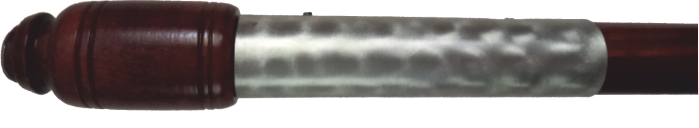

Place wire wool on your thumb, press into the surface of the metal. Then, rotate your thumb / hand right and left. Repeat this, until the surface area is covered with the resulting pattern. The pattern looks a little like a ‘hammered’ finish. The walking stick handle shown below, has a finished produced by this technique.

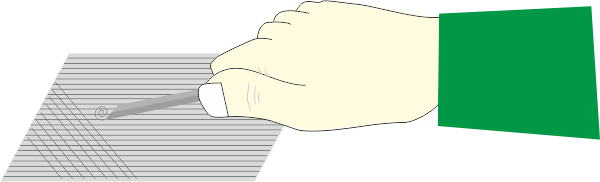

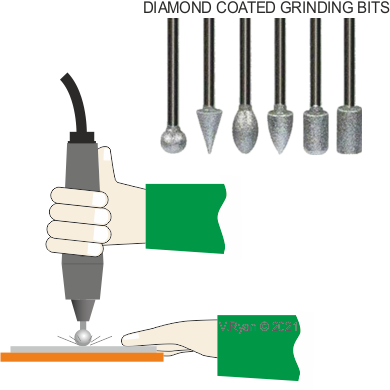

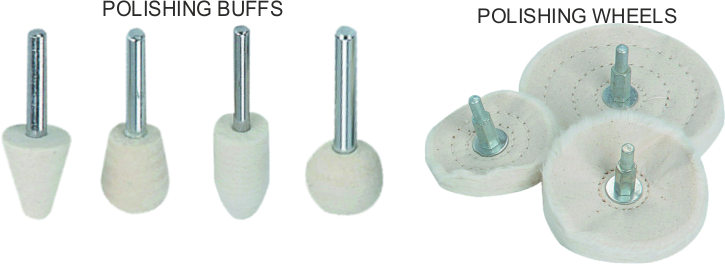

A small grinding bit, fitted to a pendant drill, can be used to produce a textured finish, more defined, than the wire wool technique. Polishing mops also produce interesting finishes.

A small selection of diamond coated grinding bits for a pendant drill, are show opposite. Each one will produce its own unique texture on the surface of metal.

When polishing, selecting the correct ‘compound’ is important. Compounds are usually suitable for non-ferrous metals.

Tripoli is for removing imperfections in nonferrous metals.

Emery is a coarse compound, ideal for de-burring and surface texturing.

White compound is for a high quality finish.

Jeweller’s Red is normally used for polishing precious metals.