| |

| CLICK HERE FOR INDEX PAGE |

| |

| MACHINE ROUTERS |

| V. Ryan © 2006 - 2023 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

| Machine routers are extremely versatile machines.

They are generally used to cut grooves in natural wood and manmade

boards. They have a cutter that rotates at high speed - as the operator

pushes the router forwards the cutter removes the wood in its path. They

can be very dangerous if not used with care and attention to safety

rules. |

| |

|

| |

|

|

| |

1. The mains

electric cord is carried over the shoulder of the operator so that it

does not get in the way of the router as it is pushed forward.

2. It is good practice to use a

circuit breaker. This will cut power if any electrical fault in the

router is detected.

3. Always wear safety goggles to

protect the eyes. Never operate equipment like this without eye

protection. Wear a face mask to prevent breathing in the dust that is

created.

4. Hold both handles when using the

router. It is possible to switch the router on/off with the thumb of the

left hand (see example above).

5. Push the router forward slowly.

Look carefully at the diagram shown above - this shows the direction to

move router. If this is done incorrectly, the wood will be pulled into

the cutter rapidly. This can be very dangerous and it will also damage

the wood being worked on.

6. Always seek instruction /

training from an appropriately qualified instructor before using any

tools, especially power tools. |

| |

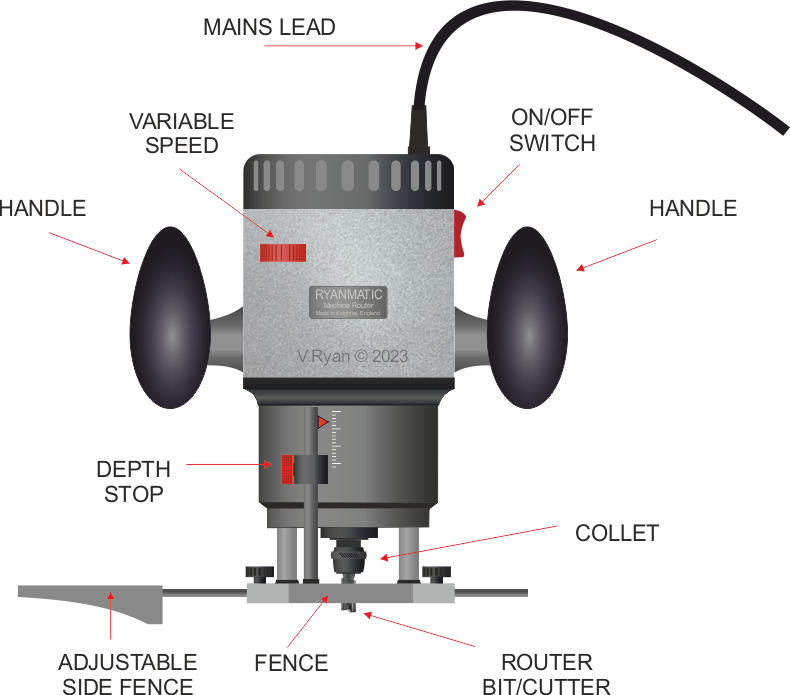

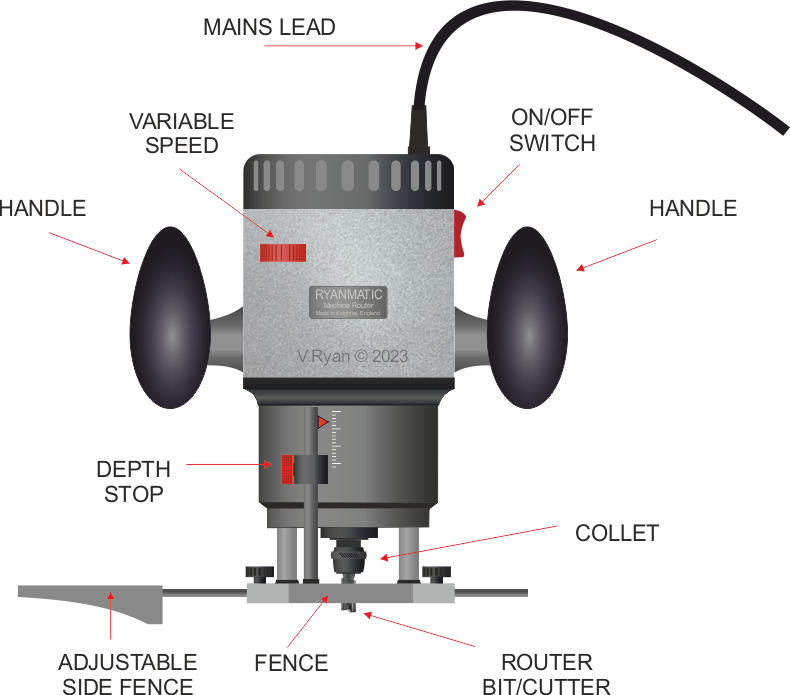

| The diagram below shows a typical machine router. A

wide range of cutters are available and they are fitted in the collet,

using a couple of small spanners. |

| |

|

| |

|

|

| |

Diagram A and B show the same typical

plain router bit. The router bit has two hardened steel cutters,

ground to an angle of approximately 30 degrees. As they rotate

they remove the waste wood.

Sometimes a bearing will be fitted to the router bit (DIA. B). This is normally done when

the outside edge of a piece of wood is to be rebated or a mould

applied to the edge. |

| |

|

| |

| CLICK HERE FOR POWER TOOLS INDEX PAGE |

| |