| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

|

Large bins usually have

wheels to ensure that they are easy to move. When the bin is standing the

wheels are off the ground. However, if the bin is tilted backwards by the

handle the wheels come into contact with the ground. The bin can then be

moved fairly easily. Bins of this type are normally manufactured from Polyethylene (PEHD) / polypropylene. This ‘plastic’ is normally pigmented - so that the final product is coloured. The two wheels are normally fixed to an axis. |

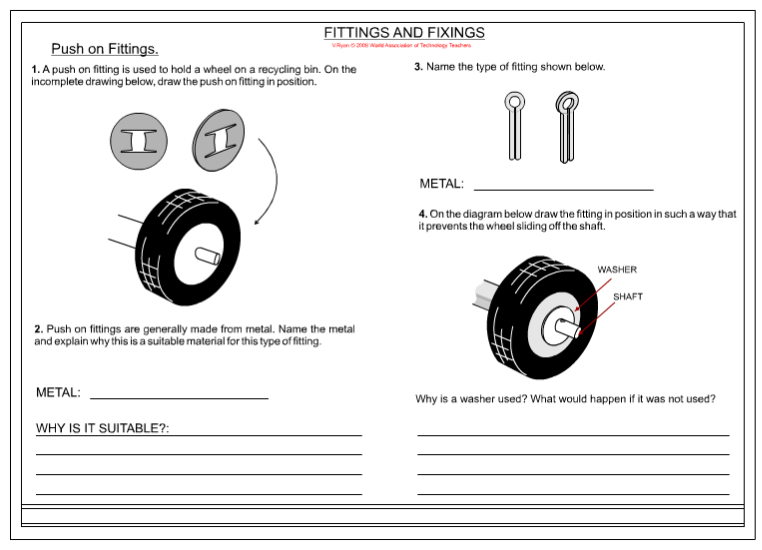

| PUSH ON FITTINGS | |

|

Push on fittings are very popular as they are simply pushed onto the steel / plastic shaft. They are made from hardened spring steel which makes them tough and flexible. They can only be pushed in one direction only(forwards). To remove them they must be forced backwards, this will damage them so that they cannot be used again. As they are very cheap and disposable, they can be replaced. They are suitable for light wheeled vehicles such as light trolleys. |

|

Split pins are very

common as they are easy to use and effective. Often they are found on

self-assembly trolleys, light wheel barrows, lawn mowers and similar

items. They are usually made from ‘soft’ steel or aluminium and they come

in a range of sizes. The shaft/axle is normally drilled so that the split pin can drop through or can be ‘tapped’ through with a hammer. The legs of the split pin are then bent to form an angle, holding the split pin and wheel in place. A washer can be used to reduce friction between the split pin and the wheel. Split pins are strong but after time they can wear and break. |

| EXAMINATION QUESTION | |

|

|

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | |