| CLICK HERE FOR INDEX PAGE | ||

| REVISION CARDS - SOFTWOODS | ||

| V. Ryan © 2012 | ||

|

PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

||

|

WHAT ARE

SOFTWOODS ? Softwoods are from trees that have needles / exposed seeds, not leaves. They grow quickly, compared to most hardwoods. When sawn and planed they tend to be light/pale in colour. Softwoods also tend to be cheaper than hardwoods. Softwoods are used by the construction industry and are use to produce paper pulp, and card products.  |

SOFTWOODS 1 - PARANA PINE Virtually knot free with straight grain, making it ideal for a range of uses. Light brown. Very easy to cut and shape, meaning accurate work is easier to achieve than with most softwoods and hardwoods. A smooth finish can be achieved. Used in the manufacture of furniture. Often used for turning wood products. Used to manufacture plywood.  |

|

|

SOFTWOODS 2 - SCOTS PINE Sometimes called Red Deal. A popular natural wood. Can be resinous and have plenty of knots. Coloured from light yellow to dark brown. Can be shaped and formed reasonably easily by handtools and machines. Often used for furniture and the construction industry. Used for interior work. One of the most commonly used woods.  |

SOFTWOODS 3 - RED CEDAR Has a pleasant aroma, when cut and machined. Its straight grain means that it works well with tools and machines. Starts as reddish brown in colour, after weathering turns to a silver grey. Used for decking, furniture and general construction. Used for roof shingles, due to its resistance to all weathers.  |

|

SOFTWOODS 4 - YEW Straight grained which means it can be shaped and formed quite easily. However, the grain can sometimes be difficult to work. An oily wood that resists natural degradation from the weather and elements.. Used to manufacture both interior and exterior furniture e.g. chairs, gate posts and wood turning.  |

SOFTWOODS 5 - DOUGLAS FIR A reddish brown wood and relatively knot free. Good to work with handtools and machinery. When smoothed to a fine finish, the grain tends to standout from the surface. Used extensively in the construction industry and in the production of plywood. Also used in a range of joinery work.  |

|

SOFTWOODS 6 - SEQUOIA A reddish to brown wood with a texture that varies from smooth to coarse. Can be worked quite easily with handtools and machines. Glass paper produces a good, smooth finish. Used regularly as roof shingles, due to its resistance to the weather. Used for interior and exterior joinery.  |

SOFTWOODS 7 - LARCH High in resin and straight grained. Pale red to brick red. Can be worked reasonably well with handtools, if knots are avoided. It is a tough softwood and has a range of uses including; boat planking, window frames, floors and staircases.  |

|

| QUESTIONS | ||

| 1. Write a general description of the nature of softwoods. | ||

| 2. Complete the paragraph on Parana Pine, by adding the missing words. | ||

| knot free - grain - Light - accurate - finish - plywood | ||

| 3. Name a popular softwood that is resinous and can have plenty of knots. | ||

| 4. Read the statements below and then name the softwood. | ||

| Has a pleasant aroma, when cut

and machined. Straight grain When newly cut is reddish brown in colour. After weathering turns to a silver grey. |

||

| Softwood name:_____________________________________ | ||

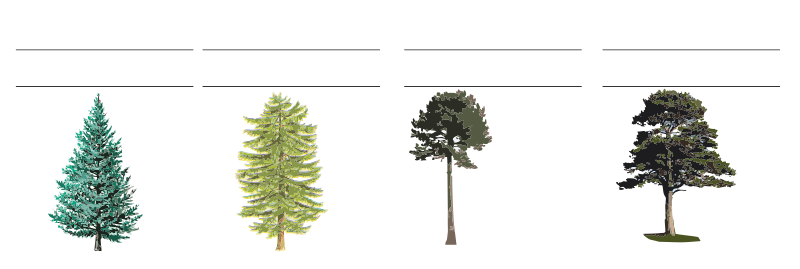

| 5. Study the trees below. Write the correct name above each one. | ||

|

||

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | ||