| PDF FILE - DIE CUTTING - BOX LEARNING EXERCISE |

| |

| Video - Die Cutter |

|

| |

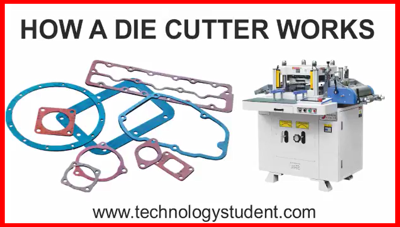

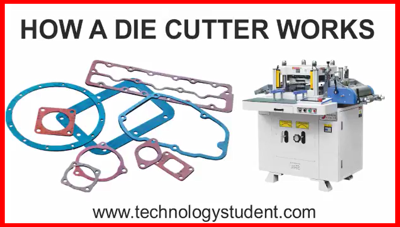

| DIE CUTTERS are normally used to manufacture card

packaging. However, they can also be used to manufacture shapes / nets /

developments from stronger materials. These include materials normally

used for models. The manufacturing techniques for the model aeroplane is exactly the same whether it is made from balsa wood or

polystyrene (Depron or Zepron) |

| |

| INDUSTRIAL MANUFACTURING

TECHNIQUES |

| |

Model gliders / aeroplanes (balsa wood / polystyrene) are usually

manufactured using a steel die cutting machine.

A sheet of thin balsa wood or polystyrene is placed on the machine table

and the die cutter ‘stamps’ out the shape and the material is then

removed. |

| |

|

| |

|

|

| |

| When the balsa wood is removed - the wing, tail and

fuselage can be pushed out of the balsa wood / polystyrene. |

| |

|

| |

Rough edges are removed using glass paper or

wet and dry paper.

Balsa wood is then sealed with PVA and allowed to dry over night.

Paint is then applied, usually by hand. (normally the glider / plane will

be supplied to the customer |

| |

|

| |

|

|

| |

| CLICK HERE FOR

GRAPHICS INDEX PAGE |

| |

| CLICK HERE FOR RESISTANT MATERIALS INDEX

PAGE |

| |