| CLICK HERE FOR INDEX PAGE |

| |

| FLOCKING - POLISHING (BUFFING) - LASER ETCHING |

V.Ryan © 2019 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

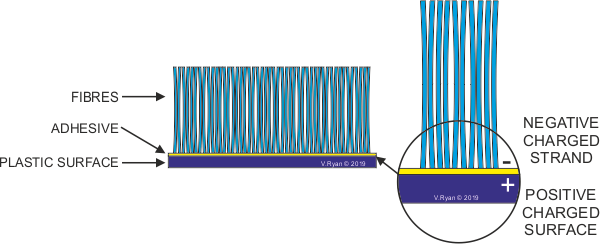

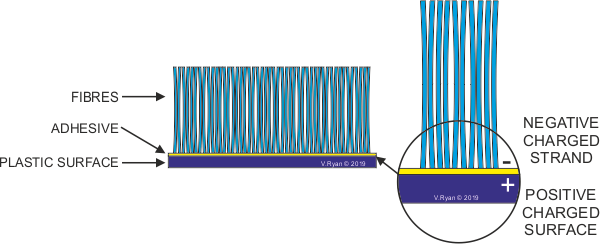

Flocking is a processes whereby, fine synthetic fibres, are applied to a surface. This is achieved by electrostatically charging the fibres, so that they are attracted to the surface, standing on end. Adhesive holds the fibre to the surface. This leaves the surface soft to the touch, like a soft velvet texture. Plastic / polymer products are sometimes flocked. |

| |

|

| |

|

|

| |

| SAMPLE FLOCKED POLYMER PRODUCTS |

| |

|

| |

| |

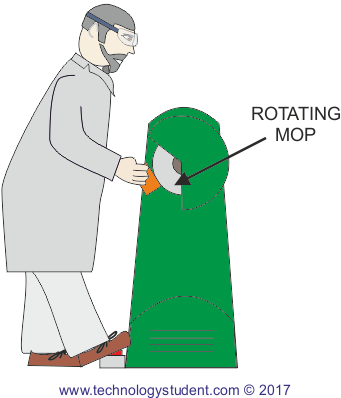

| BUFFING / POLISHING |

| |

Plastics are often given a polished finish. This is normally along edges, achieved through the use of a buffing / polishing Machine. The edge of the plastic is filed, smoothed with wet and dry paper and then finally polished on the ‘mop’ of the polishing machine.

This gives a shiny / reflective surface finish.

Click here for more on Buffing / Polishing |

|

|

| |

|

|

| |

| LASER ETCHING |

| |

A laser cutter can be used to produce an engraved finish. This is where the surface of material has a pattern or texture cut into its surface, but not all the way through. Photographs are often etched into the surface of materials such as plastics. This is achieved by reducing the power of the laser, so that only the surface is ‘etched’. The example below shows a coat of arms, being etched into a decorative plastic panel.

Click here for detail on laser cutters. |

| |

|

| |

| |

| CLICK HERE FOR FINISHES TO MATERIALS INDEX PAGE |

| |

|

| |

|