| CLICK HERE FOR INDEX PAGE |

| |

| CASTING AND SOLDERING WITH CHARCOAL |

V.Ryan © 2021 |

| |

| Charcoal’s low heat conductivity, makes it an ideal material, as a base for soldering. It can also be carved relatively easily, making it suitable for casting. The diagram below shows a typical use. A small eyelet / ring, is being soldered to a copper jewellery blank. The charcoal block does not conduct the heat from the metal, ensuring that the metal quickly reaches soldering temperature. |

| |

|

| |

|

|

| |

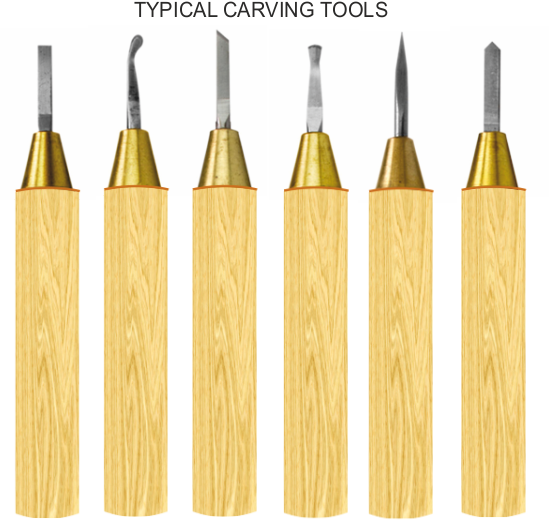

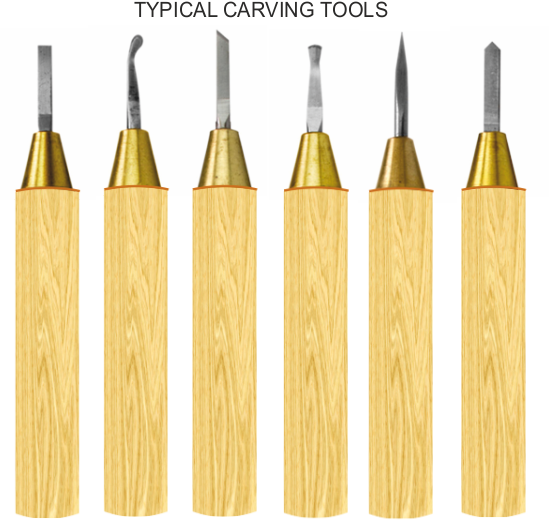

| Charcoal is relatively soft, making it easy to carve. Carving jewellery designs in the surface, can be achieved with simple tools and even homemade tools. The set of tools shown below, are actually wood carving tools, but they perform well with charcoal. |

| |

|

| |

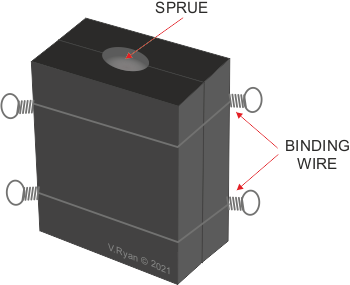

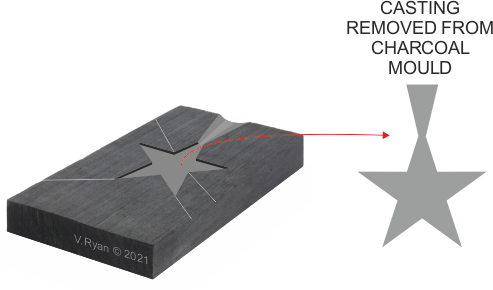

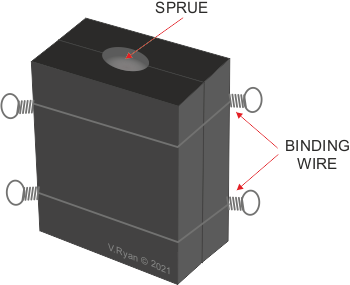

Notice a ‘sprue’ has been cut to allow the molten metal to flow into the carved cavity, of the charcoal mould. Also, thin vents are scratched into the surface, enabling air and gases to escape during the pouring of the molten metal.

A second charcoal block is prepared, by carving the second half of the sprue shape. |

| |

|

| |

|

|

| |

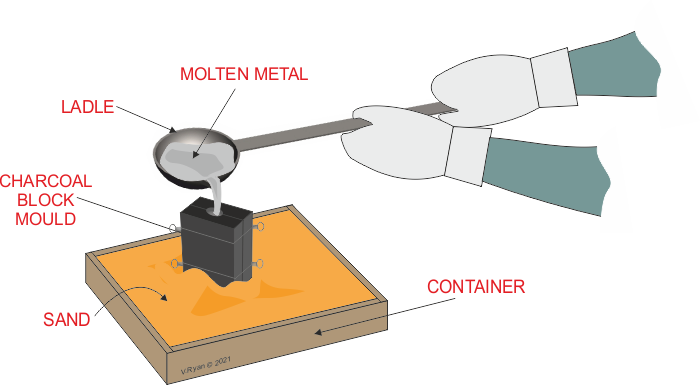

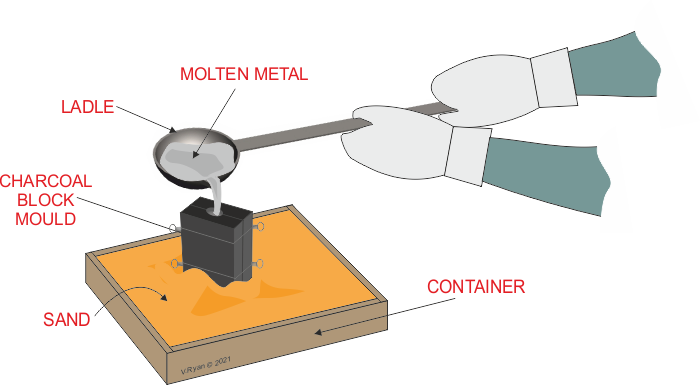

| The two charcoal blocks are wired together (or clamped). The diagram below, shows the completed mould, embedded in sand. This holds the mould in the vertical position securely. If a molten metal flows down the side of the mould or misses it completely, it will run on to the sand, harmlessly. |

|

|

| |

|

| |

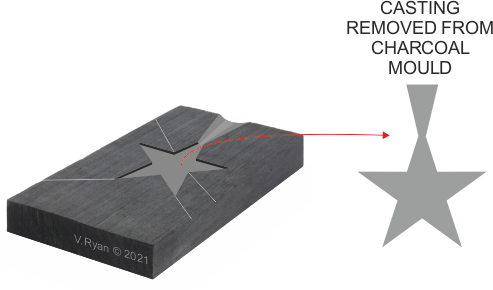

The casting is allowed to cool and the charcoal mould is split open. The casting may still be warm, so it should be placed on a steel surface / steel block to finally cool.

it is ready for finishing with files, abrasives and polishing. |

| |

|

| |

|

|

| CLICK HERE FOR JEWELLERY INDEX PAGE |

| |

|

| |

|