| CLICK HERE FOR INDEX PAGE |

| |

| PRESS MOULDING |

V.Ryan © 2022 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

| Press moulding can be as simple as ‘pressing’ a mould into a sheet of heated and pliable acrylic, so that it takes on the form of the mould. |

| |

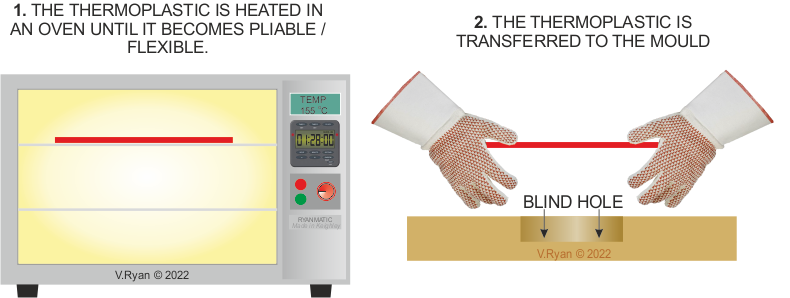

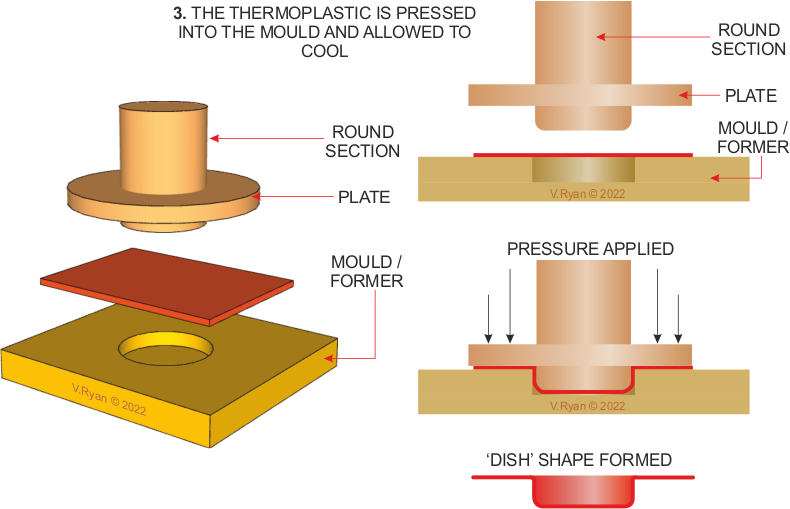

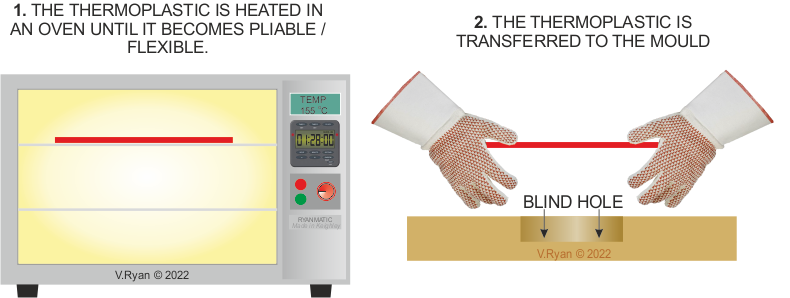

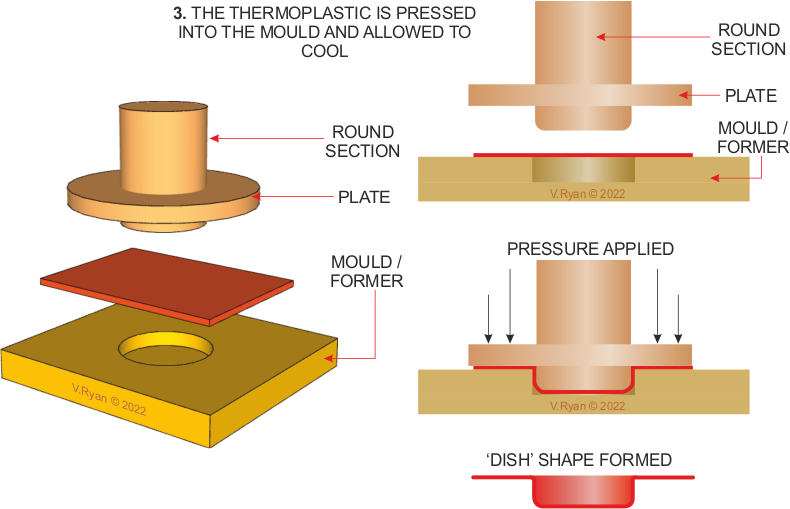

Below, a small strip of heated acrylic is placed on top of a piece of pine, directly over a ‘blind’ hole ( the former / mould ).

A piece of round section of wood is pressed into the acrylic, forcing a portion of the acrylic into the blind hole, forming a ‘dish’ shape.

The ‘plate’ is part of the round section and holds the acrylic ‘flat’ on the surface of the mould. |

| |

|

| |

|

|

| |

|

| |

| ANOTHER EXAMPLE OF PRESS MOULDING |

| |

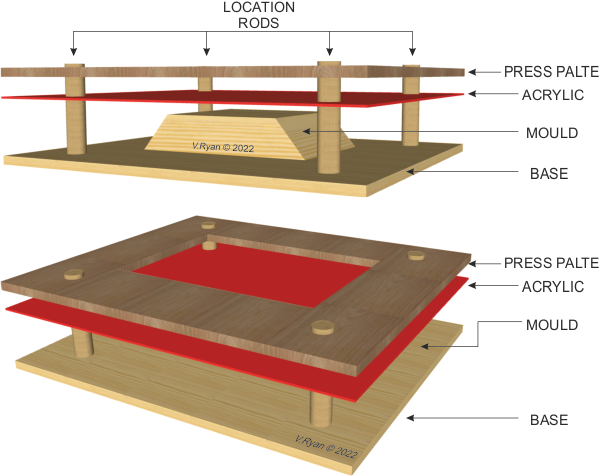

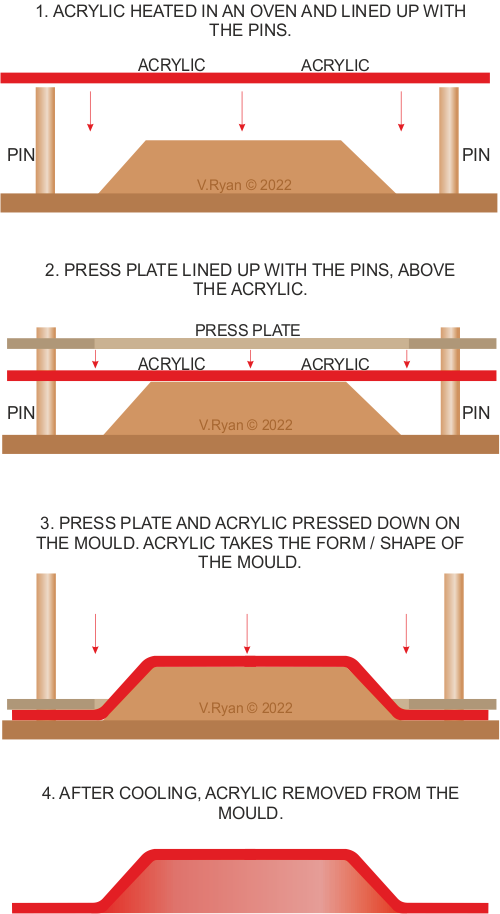

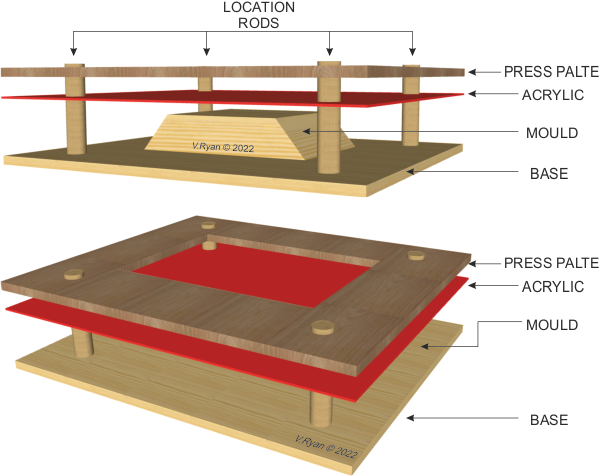

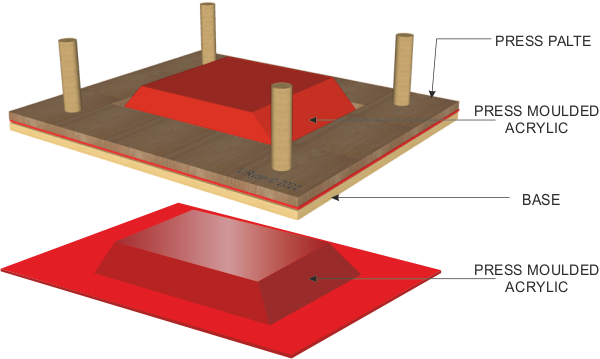

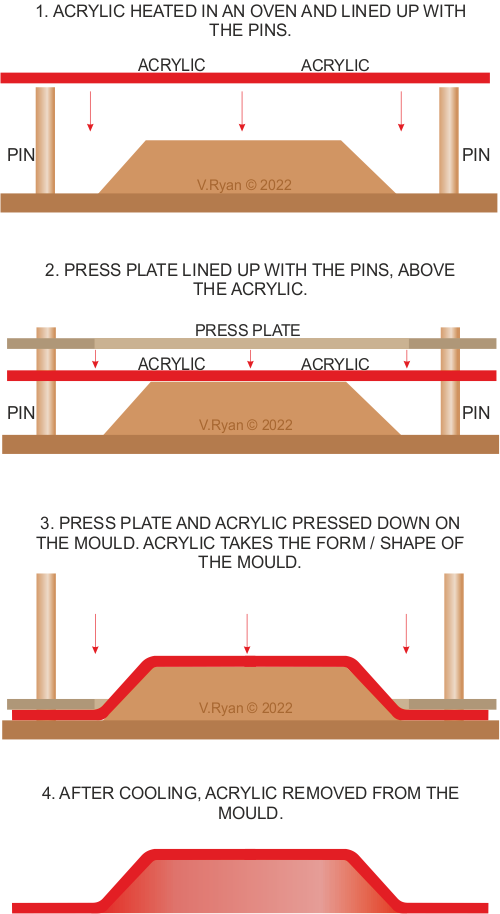

| Press moulding can be more sophisticated, as seen below. A sheet of acrylic is drilled at each corner. The holes line up with the location pins on the mould. A press plate is also drilled in the same positions, in each corner. The acrylic is heated until it becomes pliable and it is placed above the mould, with the press plate placed above it. |

| |

|

| |

|

|

| |

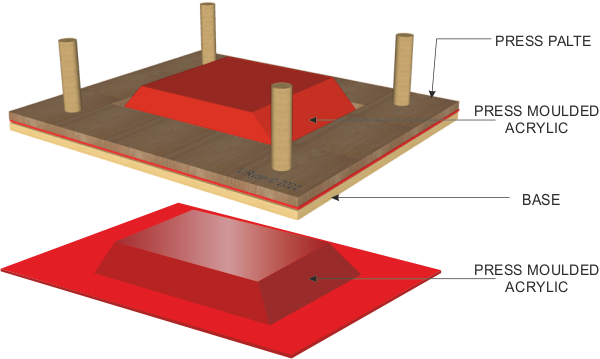

| The acrylic and press plate are pushed down on to the mould, forcing the acrylic to take its shape. When cooled, the formed / shaped acrylic is removed. |

| |

|

| |

| ANIMATION OF THE PRESS MOULDING OF PLASTICS |

| |

|

| |

|

|

| PRESS MOULDING - STAGE BY STAGE |

| |

|

| |

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|