V.Ryan © 2021

| CLICK HERE FOR INDEX PAGE |

| METAL SPINNING TOOLS |

V.Ryan © 2021 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| The spinning tool shown below, is one of the most common. The ‘roller’ spins as it is pressed against the rotating metal on the lathe. The heat created by contact between the ‘roller’ and the metal, is minimised by the rotation of the roller. Wide rollers are used to smooth the surface of the spinning metal, whereas, thinner rollers are used in the initial shaping. |

|

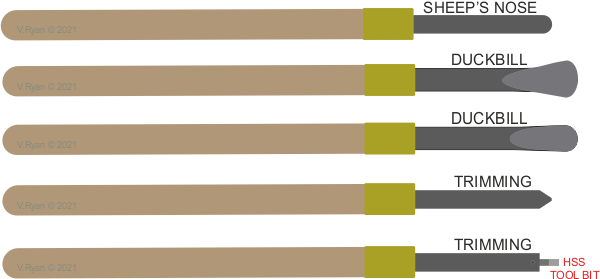

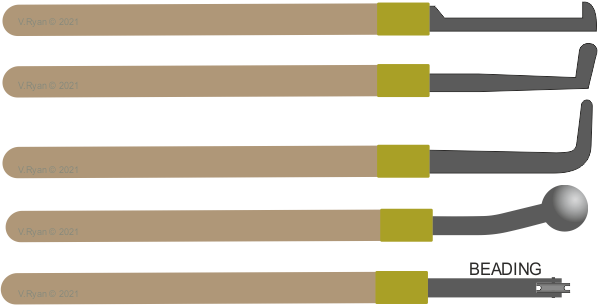

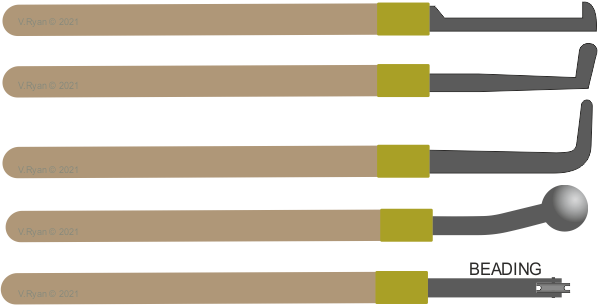

| A metal spinning tool is occasionally referred to as a ‘spoon’. They are made from hardened steel, when spinning aluminium. Brass is the preferred material for the tool, when spinning steel. Some of these spinning tools have names, but professional metal spinners, often make tools to suit their needs and the shapes they are forming. |

|

|

| LUBRICANTS FOR SPINNING |

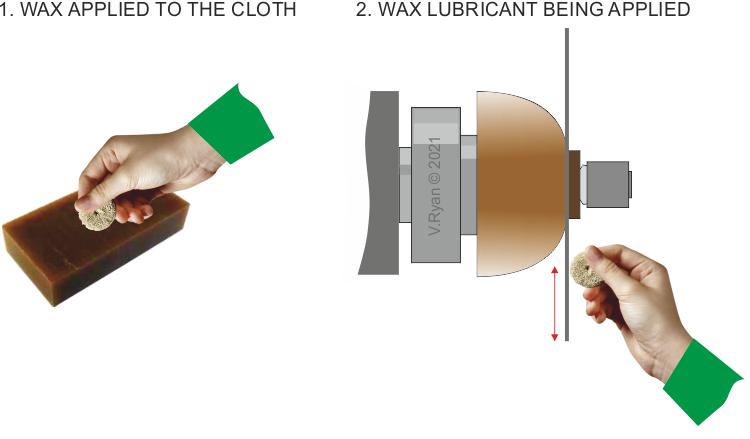

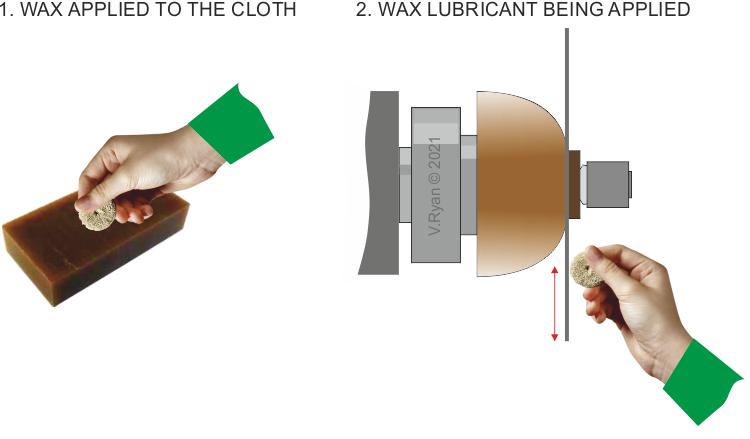

| When metal spinning tools are pressed against the rotating metal, friction is created. To reduce this, a lubricant is applied to the metals surface, with a brush or cloth . A variety of waxes (e.g. brown spinning wax) and greases can be used. Solid wax bars, that are a blend of beeswax and other ingredients, are also suitable for this process. The lubricant helps produce a fine glossy surface and prevents tearing of the metal. |

|

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

|