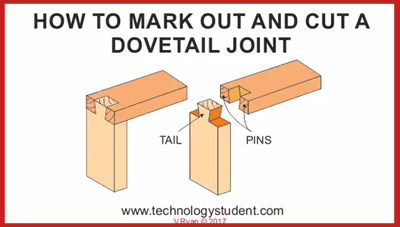

MARKING AND CUTTING OUT THE

DOVETAIL JOINT (THE TAIL)

| CLICK HERE FOR INDEX PAGE | ||

MARKING AND CUTTING OUT THE DOVETAIL JOINT (THE TAIL) |

||

| V. Ryan © 2003 - 2017 | ||

| YouTube Video - Marking Out and Cutting a Simple Dovetail Joint | ||

|

||

|

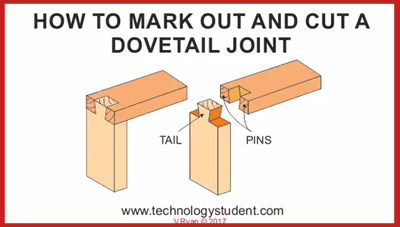

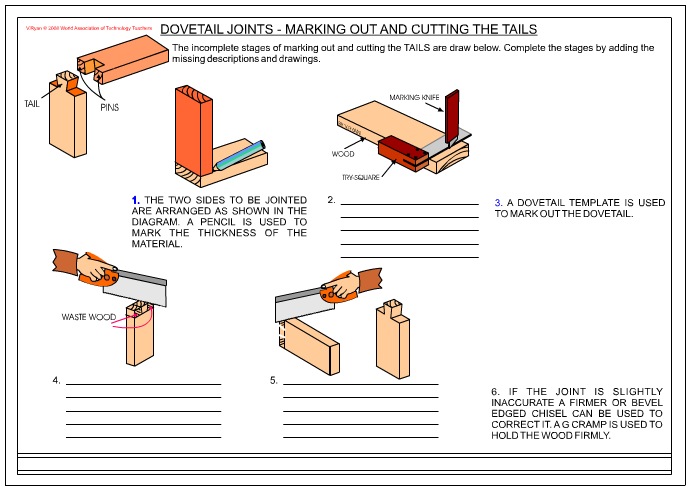

The ‘DOVETAIL JOINT’ is very strong because of the way the ‘tails’ and ‘pins’ are shaped. This makes it difficult to pull the joint apart and virtually impossible when glue is added. This type of joint is used in box constructions such as draws, jewellery boxes, cabinets and other pieces of furniture where strength is required. It is a difficult joint which requires practice. There are different types of dovetail joint and when cut accurately they are very impressive and attractive. The joint is strong especially when used with a good quality glue such as PVA (woodworkers adhesive) or cascamite. The marking out and cutting procedure is outlined below. | |

|

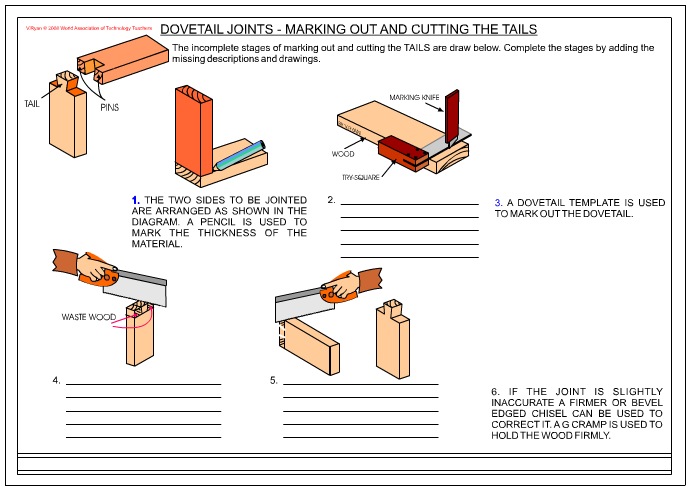

1. The two sides to be jointed are arranged as shown in the diagram. A pencil is used to mark the thickness of the material. | |

|

2. A marking knife and a try square are used to mark all the way round the material. It is possible to use only a pencil but a marking knife is more precise and it has the advantage of cutting the wood fibres. This means when a saw is used to cut the joint the surface of the wood is less likely to split. | |

|

3. A dovetail template is used to mark out the dovetail. A sliding bevel can be used also by setting it to the required dovetail angle. The waste wood should be shaded with a pencil. This will help you avoid cutting away the wrong part of the joint. | |

|

4. The wood is placed in a vice. It must be vertical so that the dovetail or tenon saw is always cutting down in a straight line. Avoid putting the wood in the vice at an angle as it will be virtually impossible to use the saw accurately. When cutting it is important to cut on the waste wood side of the line. It should be possible to see the marking out lines after the saw has been used. | |

|

5. The wood is then turned sideways in a vice and the waste material is finally removed using a dovetail or tenon saw. | |

|

6. If the tail is slightly inaccurate a firmer or bevel edged chisel can be used to correct it. A G cramp is used to hold the wood firmly. Scrap wood is placed underneath to protect the surface of the bench from the chisel. The first side of the joint should now be complete. | |

| PDF FILE - CLICK HERE FOR PRINTABLE VERSION OF EXERCISE SHOWN BELOW | ||

|

||

| CLICK HERE FOR MARKING OUT AND CUTTING THE PINS | ||

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | ||