| CLICK HERE FOR INDEX PAGE | |

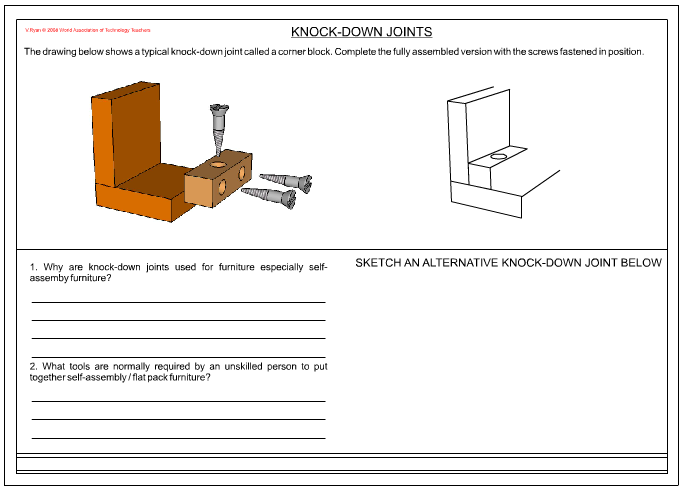

| KNOCK-DOWN (K/D) JOINTS | |

| V. Ryan © 2003 - 2008 | |

|

Knock-down fittings are those that can be put together easily, normally using only a screw driver, a drill, a mallet/hammer and other basic tools. They are temporary joints although many are used to permanently join together items such as cabinets and other pieces of furniture that are purchased in a flat pack. |

|

|

PLASTIC CORNER BLOCK (FIXIT BLOCKS): The corner block is pressed against the two pieces of material (normally wood based). Screws are used to fix the block into position. This type of joint is used to fit modern cabinets such as those found in a kitchen. It is a relatively strong joint although it has the advantage that it can be dismantled using a screwdriver. |

|

|

|

|

NATURAL WOOD FITTING (SQUARE SECTION BATTEN): A piece of material such as pine can be drilled and screws can be passed through these holes. This gives a cheap and effective knock-down joint. The screws are normally countersunk into the knock-down fitting. |

|

|

TWO BLOCK FITTING (LOK-JOINTS): These are made from plastic. A bolt passes through the first fitting into the thread of the second. As the bolt is tightened it draws the two fittings together. The pins help keep the fitting straight. This gives a very strong joint and it can be dismantled using a screwdriver. |

|

|

|

|

|

RIGID JOINT: These are normally moulded in plastic which makes them strong. Screws pass through the four holes which hold the sides at each corner firmly together. |

|

|

|

|

PDF FILE - CLICK HERE FOR PRINTABLE VERSION OF EXERCISE SEEN BELOW |

|

|

|

|

|

QUESTION: Draw two examples of knock-down fittings and explain how they are used. Include diagrams and notes. |

|

|

|

|