| CLICK HERE FOR INDEX PAGE | |

| SINGLE ITEM PRODUCTION | |

| V. Ryan © 2005 - 2023 | |

|

This is when only one item is made and is sometimes called ‘one-off production’. Sometimes a company will make one item and test it to see if it works or if it needs to be improved. This is called a prototype. Single item manufacture usually involves skilled people carefully making a special product for a customer, such as a piece of jewellery. |

|

|

CASE STUDY - SPECIALIST, BESPOKE BENCH MANUACTURERS |

|

|

|

|

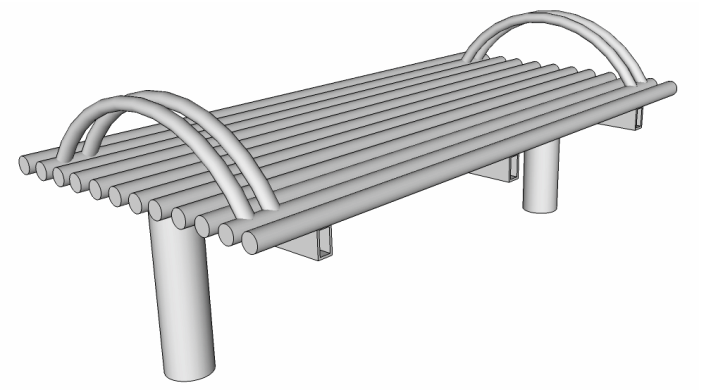

The company described below specialises in manufacturing bespoke / designer benches. These are not mass produced, they are made individually by highly skilled people. They are manufactured from top quality materials and are expensive. Consequently, local councils or the owners of private parks / leisure parks, tend to be the clients / customers. The client (customer) expects a personal service, in which he/she is interviewed several times before a design is produced and manufactured. A specialist item such as a handmade bench may take months to complete. |

|

|

|

|

|

|

|

|

|

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET | |

|

Question: In each of the boxes of the flow chart shown below, write the key words representing each stage. Starting with the customer (client) approaching the company about a design and finish with the completed bespoke bench being handed to the customer. |

|

|

|

|

|

|

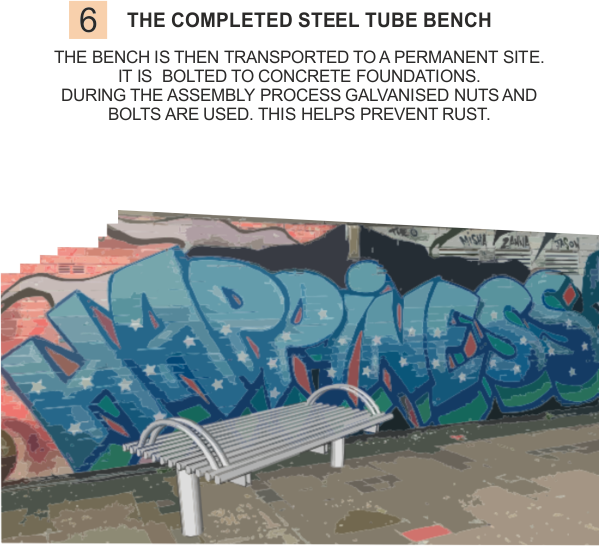

This company is made up of two people. They make bespoke benches for customers that want an ‘exclusive’ design. When made, the bench will be expensive because it will be hand made from quality materials and its manufacture will require practical skills. All this takes a long time. |

|

Usually customers want an unusual or special bench, in this case a council wants a series of benches for a park. An common bench will not spark the public interest, the council is hoping to create. |

|

|

A council is prepared to spend a lot of money on a bespoke series of benches. This means that a series of meetings will take place between council representatives and the manufacturing company. A variety of design will be discussed / considered. |

|

|

When the council representatives have discussed designs, materials and cost with the company, they will make the final decision regarding the design they want. Regular meetings and updates take place. A contract is signed. |

|

|

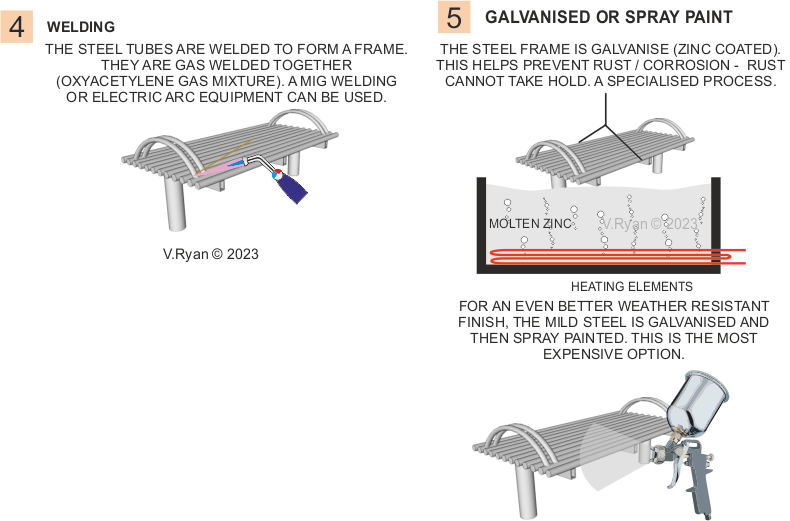

The bench is made by the skilled workers. A month has been agreed regarding manufacturing and delivery of the first bench. |

|

|

Question: |

|

|

|

|