| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

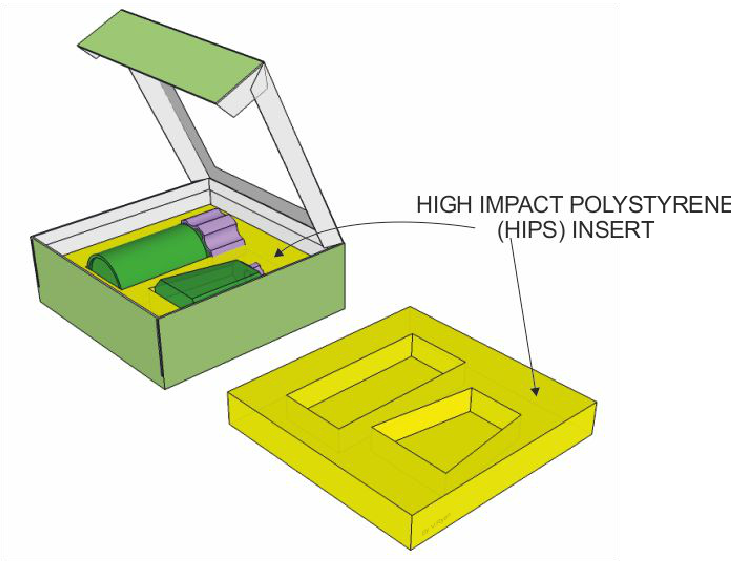

| Study the packaging for perfumed products seen below. | |

|

|

| 1. Explain why high quality card is needed to manufacture the box. | |

|

High quality card will ensure that the colours printed on its surface,

will appear bright and sharp. Quality card has a superior feel when

handled by potential customers, suggesting that there is a quality product

inside the packaging. Good quality card is less flexible than cheaper card and can be scored and folded without the surface breaking or being damaged. Flat surfaces hold their shape and are less likely to warp, crease or bend out of shape. Printing adheres more accurately to good quality card because the cards surface is resistant to bending and breaking. This gives a flat surface on which to print. |

|

| 2. Name a material that is suitable for the polymer insert of the mobile phone packaging. | |

| High Impact Polystyrene (HIPS). | |

| 3. Why is the material you have named, the most suitable? | |

|

High Impact Polystyrene (HIPS) is the most suitable as it is available

in transparent form and can be moulded accurately, to the shape of the

insert. Vacuum forming is the manufacturing process through which the shape can be manufactured. HIPS can be recycled relatively easily, if disposed of in the relevant recycling bin. HIPS has a short life cycle. |

|

| 4. List other polymers that could be used for the polymer insert. | |

|

Other materials that could be used are: Plastic forming films such as polyvinyl chloride (PVC), polypropylene (PP) and polyester (PET) are formed through the use of heat, and are usually colourless and transparent. |

|

| CLICK HERE FOR PRODUCT DESIGN INDEX PAGE | |