| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

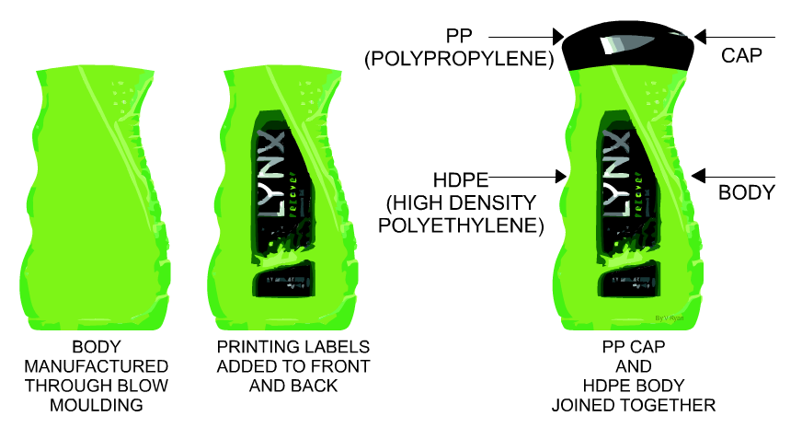

| The body of the perfumed product (shower gel) container, has been manufactured through a process called ‘blow moulding’. | |

|

|

| HDPE is supplied in a range of colours. It is relatively cheap compared to other plastics. HDPE is a thermoplastic and it can be moulded when heated. It can be recycled (down cycled) into other products. | |

|

|

|

1. Granules of HDPE are added to the hopper. 2. The granules fall on to the archimedean screw which pushes them through the heater. 3. The granules melt and become mouldable. 4. As the molten HDPE is forced into the mould, a ‘jet’ of compressed air forces it to the outside wall of the mould, forming the body of the container. 5. When the HDPE cools, it can be removed from the mould. |

|

| CLICK HERE FOR PRODUCT DESIGN INDEX PAGE | |