| CLICK HERE FOR INDEX PAGE | |||||||

| CORDED HAMMER DRILLS | |||||||

| V. Ryan © 2006-2023 | |||||||

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |||||||

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET | |||||||

| Corded Hammer Drills have a wide range of uses. Corded drills are powered directly by plugging into the main electricity supply and this means that extra care must taken regarding safety. | |||||||

|

|||||||

| SAFETY | |||||||

|

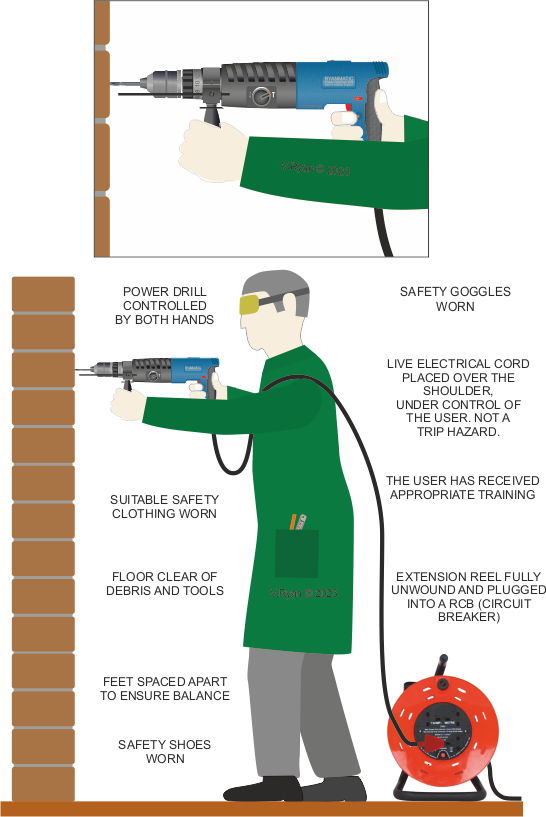

1. The cord is carefully laid out so

that it cannot trip the person using the drill. |

|||||||

|

|

|||||||

|

4. When using a

corded drill hold both the normal handle and front handle securely. This

will help steady the drill as it vibrates during use. It also allows the

user to put pressure against the drill as it is used to drill holes in

difficult materials. |

|||||||

|

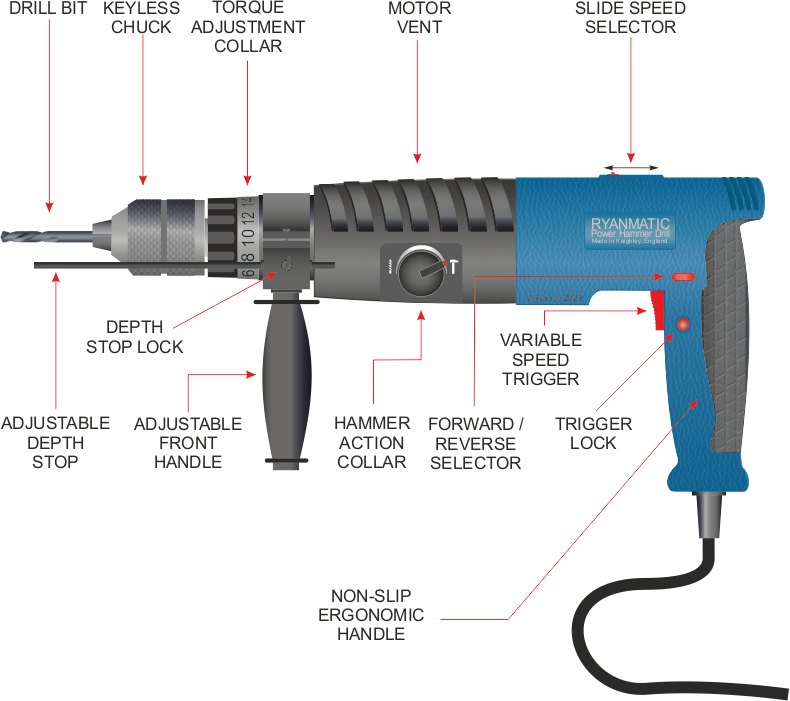

A basic corded drill is shown below. Even basic drills are provided with accessories. For instance, corded drills usually have a front handle that can be fitted if required. It is strongly recommended that the front handle is fitted as it provides extra support an makes it more likely that the drill will be used safely. If both hands are holding the drill then it is impossible for the user to accidentally place his /her hand in the way of the drill whilst it is in use. |

|||||||

|

|

|||||||

|

The drill speed (rpm, revolutions per minute) can be changed according to the material being drilled. On the example shown above the speed is changed by turning the dial on the on/off switch. This will vary depending on the model of drill being used. |

|||||||

|

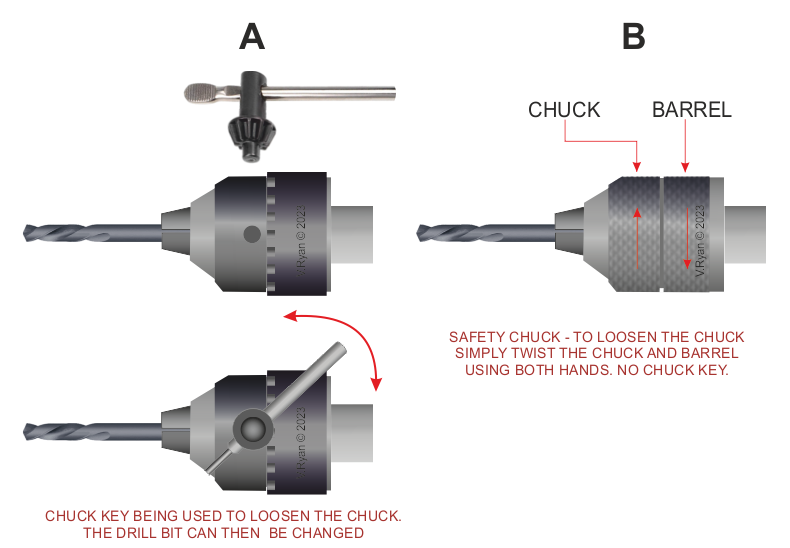

A. The drill bit is changed by using a chuck key to loosen the chuck. The bit is normally changed if a larger diameter is needed OR a different type of drill bit. For example, a normal HSS drill bit is use to drill wood / metals. However, for masonry and brick / stone a ‘masonry’ bit is required. |

|||||||

| B. Safety / self-locking chucks are very common. These do not need a chuck key and are used by simply turning the chuck and the barrel by hand, in opposite directions. The drill bit locks in position. | |||||||

|

|||||||

|

Most corded drills will have at least two basic settings - normal and hammer. This allows the drill to be used on a range of materials such as natural woods, manmade boards, metals, masonry, brick and stone. |

|||||||

|

|

|||||||

|

|||||||

|

TIP |

|||||||

|

When drilling a difficult material such as stone. Fit a masonry drill bit and start drilling on a normal setting. Once a small hole has been started, switch to the ‘hammer’ setting. If the ‘hammer’ setting is used right at the beginning, the drill bit can slip as it vibrates at high speed. |

|||||||

| USING A CORDED POWER DRILL | |||||||

|

|||||||

|

|

|||||||