| CLICK HERE FOR INDEX PAGE | |||||||||

| SHEET SANDERS | |||||||||

| V. Ryan © 2006 - 2023 | |||||||||

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |||||||||

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET | |||||||||

|

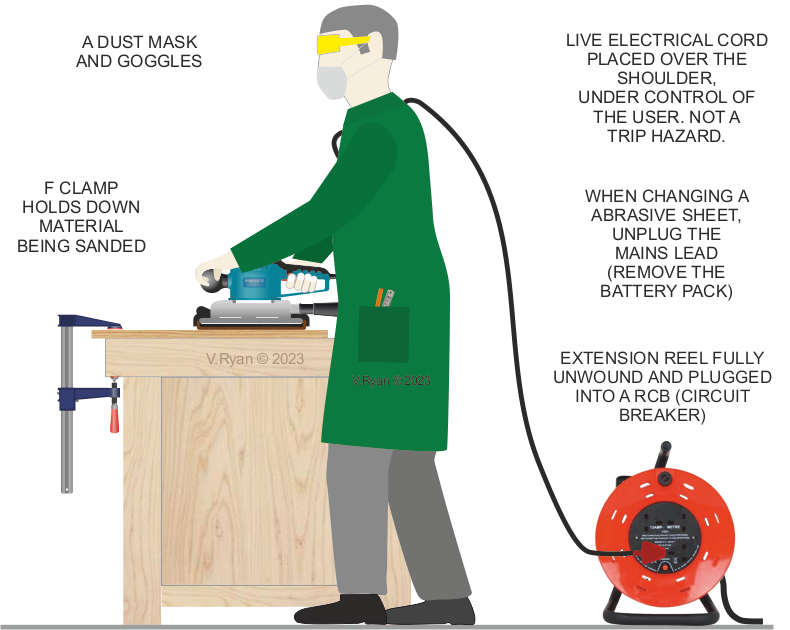

Sheet sanders are used to sand / smooth wood surfaces although they can be used to sand / smooth materials such as plastics and metals as well. When sanding wood, glasspaper is ‘clipped’ into the sheet sander. If the surface requires a lot of sanding then start with ‘coarse’ glasspaper rather than fine - as this will reduce the amount of time required. Fine glasspaper can be used to finish the surface so that it is smooth to touch. When in use the rectangular base vibrates at 1200 rpm (revolutions per minute). This ‘sands’ the surface of any material beneath it. |

|||||||||

|

|||||||||

|

|||||||||

|

1. Always plug

power tools into a RCB (circuit breaker) as a safety measure against

electrical faults. |

|||||||||

| SHEET SANDER AND GLASSPAPER | |||||||||

|

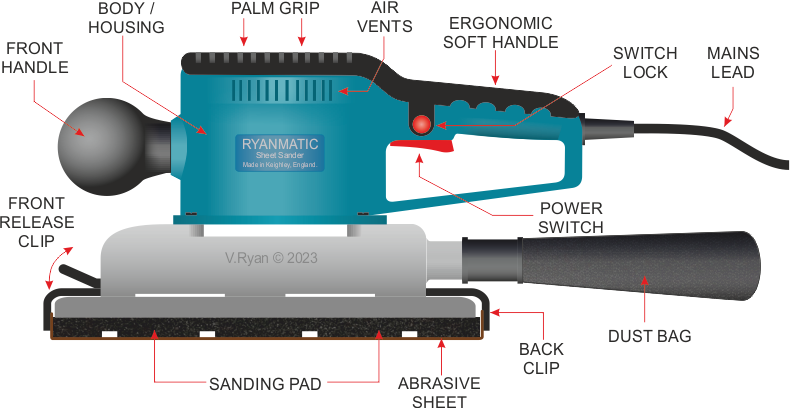

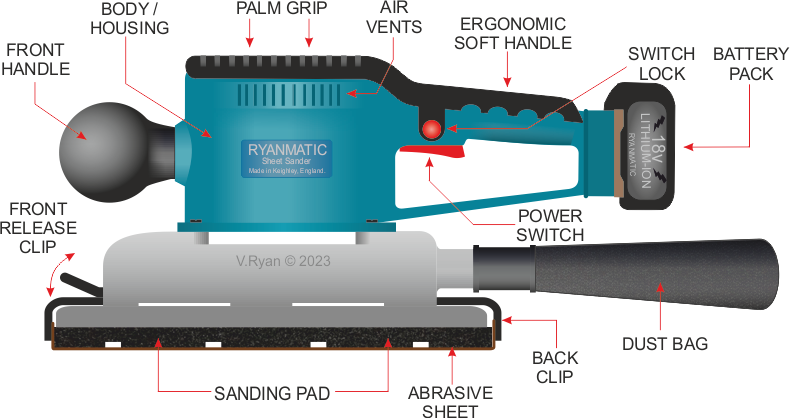

A large range of sheet sanders are available from DIY stores and catalogues. When selecting a sander ensure that it is provided with a dust extraction bag system and always plug into a RCB (circuit breaker). Modern, cheap sanders are usually good quality but if you intend to carry out a lot of sanding invest in a more expensive and better quality version. |

|||||||||

| CORDED / MAINS VERSION | |||||||||

|

|||||||||

| CORDLESS / BATTERY VERSION | |||||||||

|

|||||||||

|

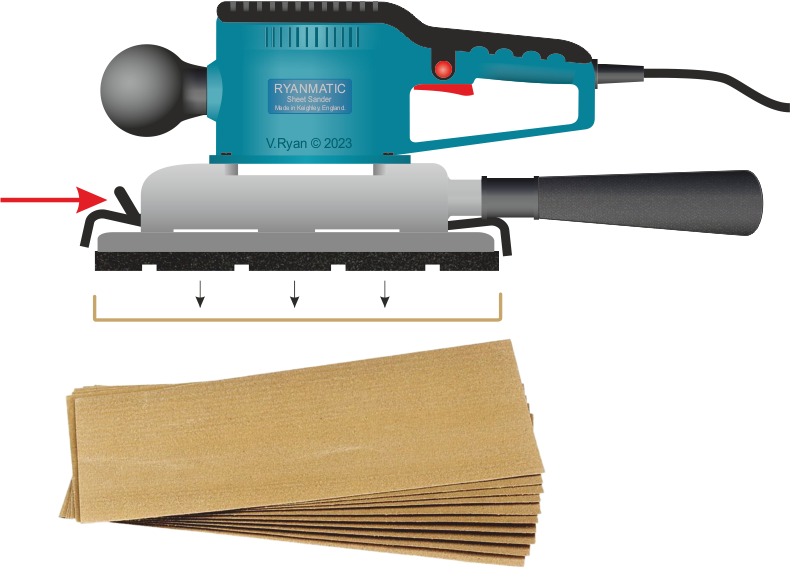

REPLACING THE GLASS PAPER |

|||||||||

| To replace worn glasspaper, press the clip at the front of the sander and pull out the glasspaper. Do exactly the same with the front clip. Clip fresh glass paper in position. | |||||||||

|

|||||||||

|

Glasspaper is manufactured from crushed glass glued to a suitable backing such as cloth or paper. People often call glasspaper ‘sandpaper’. However, the last people to make sandpaper were the Egyptians, over 4000 years ago. The various grades of glasspaper are shown below: |

|||||||||

|

|||||||||